A kind of anti-oxidation film and preparation method

An anti-oxidation, thin-film technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the loss of silver protection, the aging degradation of protective film, and the unsatisfactory weather resistance of silver discoloration agent. and other problems, to achieve the effect of improving the antioxidant effect, good film-forming performance, and improving the antioxidant capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Inorganic nano film of the present invention, SiO 2 , B 2 o 3 , ZnO and K 2 The weight ratio of O is 45:10:15:30.

[0027] Its specific preparation process includes the following steps:

[0028] 1) Preparation of precursor solution: weigh 20g TESO (tetraethyl orthosilicate), 200g H 2 O and 40g polyethylene glycol, after mixing uniformly in a 500ml beaker, adjust PH=9 with ammonia water, stir at room temperature for 12h, slowly add 0.97g (CH 3 O) 3 B, 0.57g Na 2 [Zn(OH) 4 ] and 1 g K 2 O, after the stirring is completed, a transparent sol-like solution is obtained, which is the precursor.

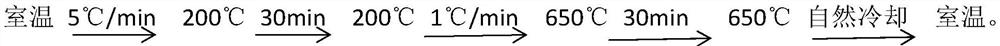

[0029] 2) Preparation of anti-oxidation silver: immerse pure silver in the precursor solution, coat with a pull coater, dry naturally, and perform heat treatment according to the following heating procedure:

[0030]

[0031] After the heat treatment, the anti-oxidation silver is obtained. The anti-oxidation silver will not be corroded and discolored in the atmosphere, sw...

Embodiment 2

[0033] Inorganic nano film of the present invention, SiO 2 , B 2 o 3 , ZnO and K 2 The weight ratio of O is 50:10:10:30.

[0034] Its specific preparation process includes the following steps:

[0035] 1) Preparation of precursor solution: weigh 100g TESO, 1000g H 2 O and 200g polyethylene glycol, after mixing uniformly in a 2500ml beaker, adjust PH=9 with ammonia water, stir at room temperature for 12h, slowly add 4.5g (CH 3 O) 3 B, 1.74gNa 2 [Zn(OH) 4 ] and 5g K 2 O, after the stirring is completed, a transparent sol-like solution is obtained, which is the precursor.

[0036] 2) Preparation of anti-oxidation silver: immerse pure silver in the precursor solution, coat with a pull coater, dry naturally, and perform heat treatment according to the following heating procedure:

[0037]

[0038] After the heat treatment, the anti-oxidation silver is obtained. The anti-oxidation silver will not be corroded and discolored in the atmosphere, sweat, hydrogen sulfide atmo...

Embodiment 3

[0040] Inorganic nano film of the present invention, SiO 2 , B 2 o 3 , ZnO and K 2 The weight ratio of O is 60:5:15:20.

[0041] Its specific preparation process includes the following steps:

[0042] 1) Preparation of precursor solution: weigh 200g TESO, 2000g H 2 O and 400g polyethylene glycol, after mixing uniformly in a 5000ml beaker, adjust PH=9 with ammonia water, stir at room temperature for 12h, slowly add 3.7g (CH 3 O) 3 B, 4.2gNa 2 [Zn(OH) 4 ] and 4.9 g K 2 O, after the stirring is completed, a transparent sol-like solution is obtained, which is the precursor.

[0043] 2) Preparation of anti-oxidation silver: immerse pure silver in the precursor solution, coat with a pull coater, dry naturally, and perform heat treatment according to the following heating procedure:

[0044]

[0045] After the heat treatment, the anti-oxidation silver is obtained. The anti-oxidation silver will not be corroded and discolored in the atmosphere, sweat, hydrogen sulfide atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com