Wet air control master valve

An air-controlled, wet-type technology, applied in the direction of control valve and air release valve, lift valve, valve details, etc., can solve the problems of easy adhesion of impurities, no filter screen in the intake chamber, and deviation of the piston coaxiality, to avoid valve Core sticking and seal damage, preventing impurities from entering the valve body, and ensuring a high degree of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

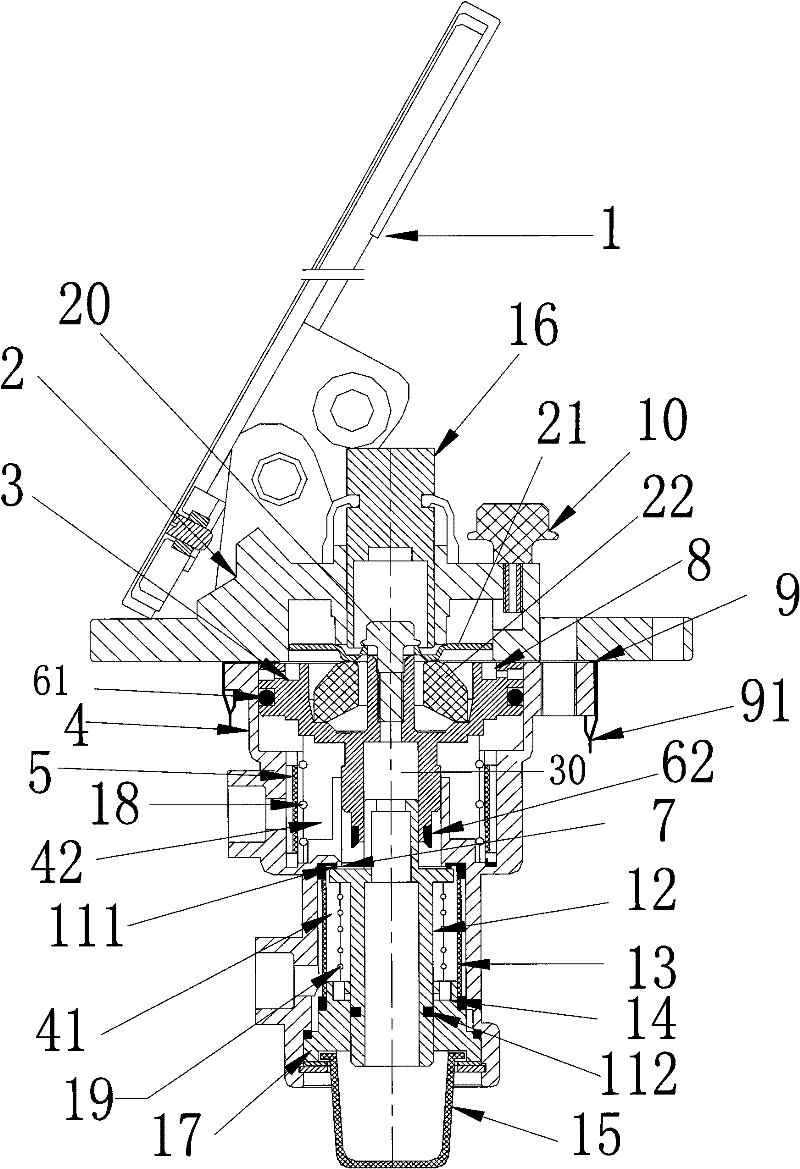

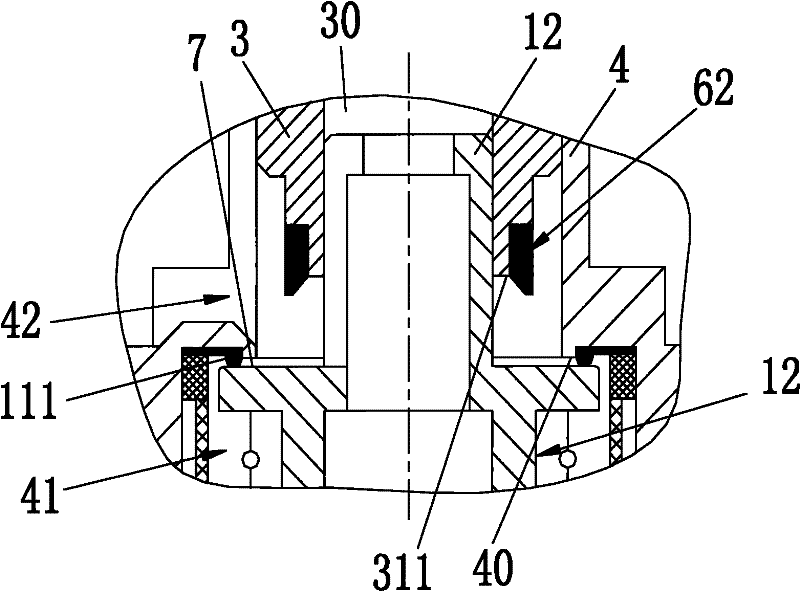

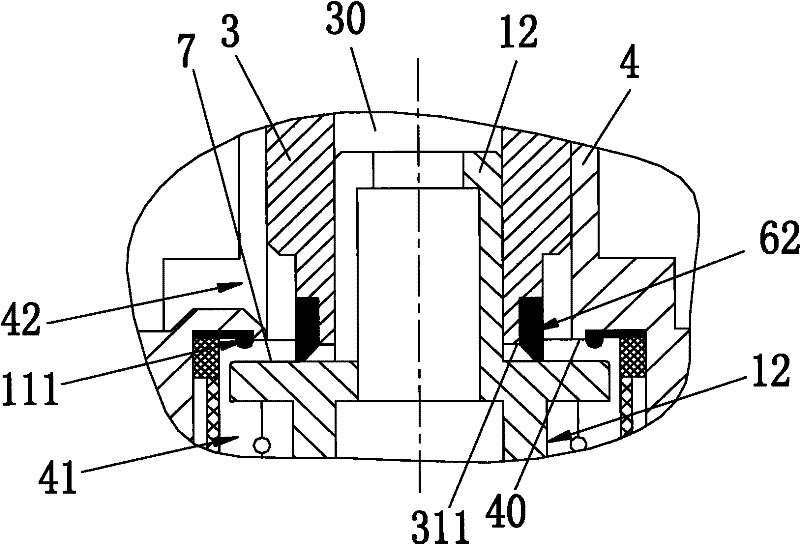

[0040] see Figure 1~3 , the embodiment of the present invention is provided with a pedal 1, a mounting plate 2, a push rod 16, a piston 3, a valve body 4, a valve core 12, a base 17, a piston return spring 18, a piston seal, a valve core return spring 19, a valve Core seal, air intake cavity filter screen 13 and air outlet cavity filter screen 5 etc.

[0041] Mounting plate 2 is fixed on the car body ( figure 1Not shown in the middle), the pedal 1 is located on the top of the mounting plate 2, and the lower end of the pedal 1 is connected with the mounting plate 2 in rotation. The push rod 16 is disposed in the mounting plate 2 and is slidingly matched with the mounting plate 2 . The pedal 1 is stepped on, and the push rod 16 is pressed to move downward. A pressing plate 21 and an elastic body 22 are arranged below the push rod 16 , and the pressing plate 21 and the elastic body 22 are connected by a fastener 20 . The push rod 16 moves downward to press the pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com