High-precision friction dynamic process testing device and method

A testing device and dynamic process technology, which is applied in the direction of measuring device, measuring force, power measurement, etc., can solve the problems of low friction test accuracy, difficulty in testing static and dynamic friction of the measured object, and inability to test friction, etc., to achieve simple structure , friction testing is accurate, and the operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

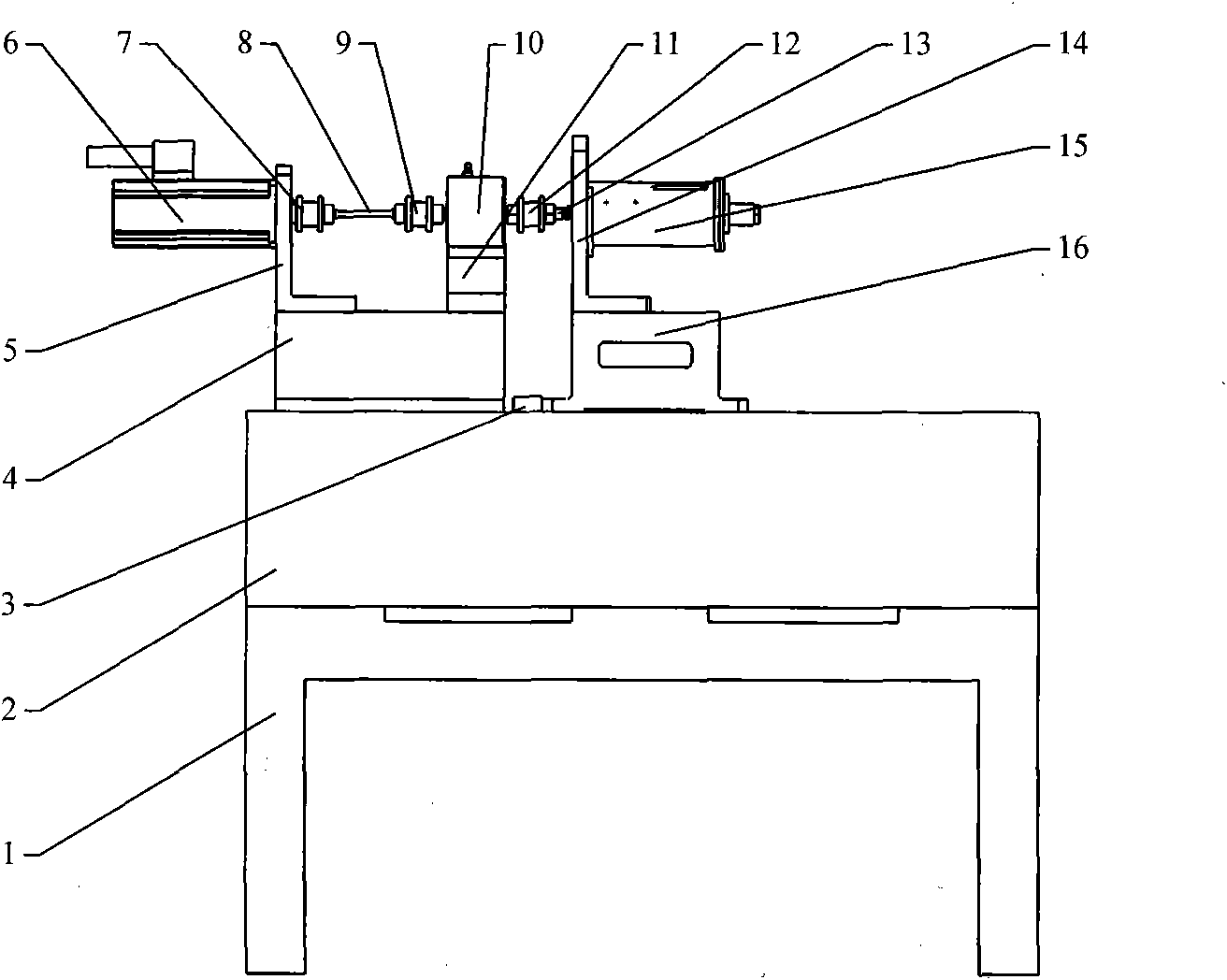

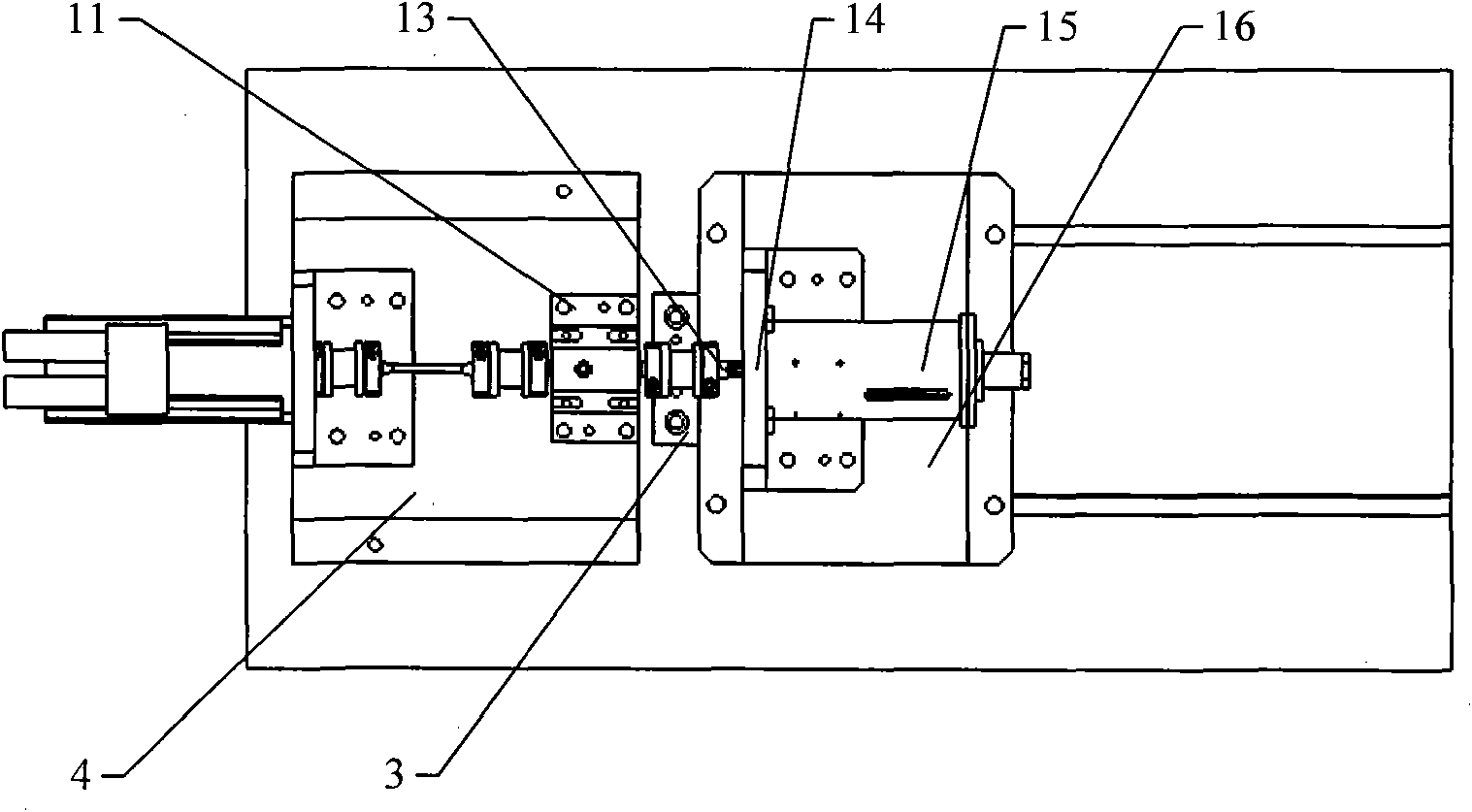

[0041] This embodiment is a device for testing the dynamic process of the friction force of the lead screw pair, including a bench, power components, tooling components of the tested piece and a control system.

[0042] Such as figure 1 , figure 2 As shown, the stand includes a bracket 1 , a table top 2 and a positioning bar 3 , and the bracket 1 is fixed to the ground, and the table top 2 is fixed on the bracket 1 . The strip-shaped positioning bar 3 whose end face is rectangular is fixed on the middle part of the upper surface of the table top 2 along the width direction of the table top 2; a pair of T-shaped slots are arranged on the upper surface of the table top 2, and the T-shaped slots are located on one side of the positioning bar 3 and are aligned with the positioning bar. Bar 3 is vertical.

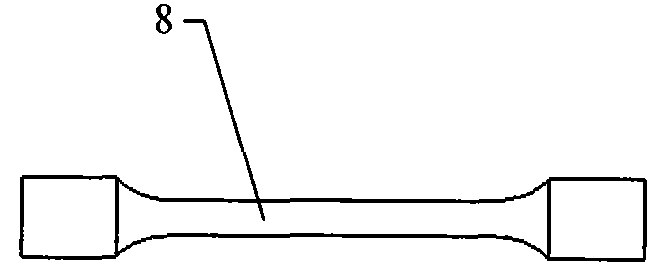

[0043]The power component includes a power component support 4, a servo motor 6 and a motor support base 5, a motor coupling 7, a torsion bar spring 8, a sensor coupling 9, ...

Embodiment 2

[0058] This embodiment is a device for testing the dynamic process of friction force of a gear pair, including a bench, a power component, a tooling component of a test piece and a control system.

[0059] Such as Figure 5 , Image 6 As shown, the stand includes a bracket 1 , a table top 2 and a positioning bar 3 , and the bracket 1 is fixed to the ground, and the table top 2 is fixed on the bracket 1 . The strip-shaped positioning bar 3 whose end face is rectangular is fixed on the middle part of the upper surface of the table top 2 along the width direction of the table top 2; a pair of T-shaped slots are arranged on the upper surface of the table top 2, and the T-shaped slots are located on one side of the positioning bar 3 and are aligned with the positioning bar. Bar 3 is vertical.

[0060] The power component includes a power component support 4, a servo motor 6 and a motor support base 5, a motor coupling 7, a torsion bar spring 8, a sensor coupling 9, a torque senso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lead | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com