X-ray sensor and fabrication method thereof

A manufacturing method and sensor technology, applied in semiconductor/solid-state device manufacturing, radiation control devices, instruments for radiological diagnosis, etc., can solve the problem of low data acquisition rate of X-ray sensors, and achieve the effect of improving the data acquisition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Aiming at the problem that the prior art X-ray sensor adopts a single-line scanning mode, which leads to a low data acquisition rate, the present invention provides an X-ray sensor, which realizes The working mode of multi-line scanning is used to improve the data acquisition rate of the X-ray sensor.

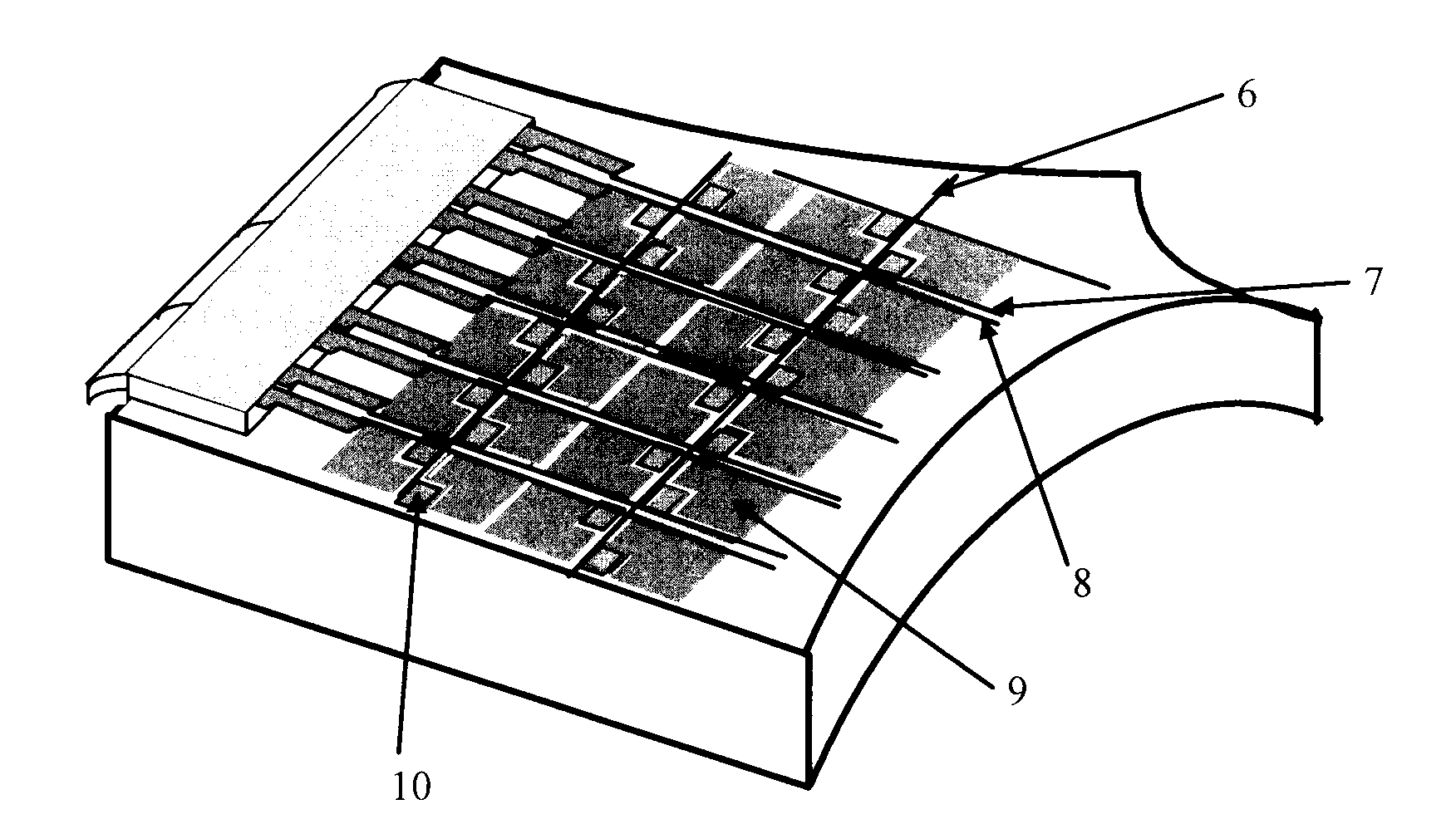

[0034] refer to image 3 As shown, an embodiment of the X-ray sensor of the present invention includes: an array of pixel units, wherein each pixel unit is composed of a photodiode 9 and a field effect transistor 10 . There are two data lines 7 and 8 between two adjacent columns of pixel units, and one scanning line 6 between two adjacent rows of pixel units. The field effect transistors in the two adjacent rows of pixel units share the same scan line, and the field effect transistors in each row of pixel units and the field effect transistors in the adjacent pixel units are respectively connected to different adjacent data lines. For example, the field effect transist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com