Electrochemical in-situ film conductivity measurer

An in-situ film and conductivity technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of limited application range of polyester film solvent resistance, low data communication rate, poor instrument integration, etc., to achieve Convenient technical measurement, efficient technical measurement, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

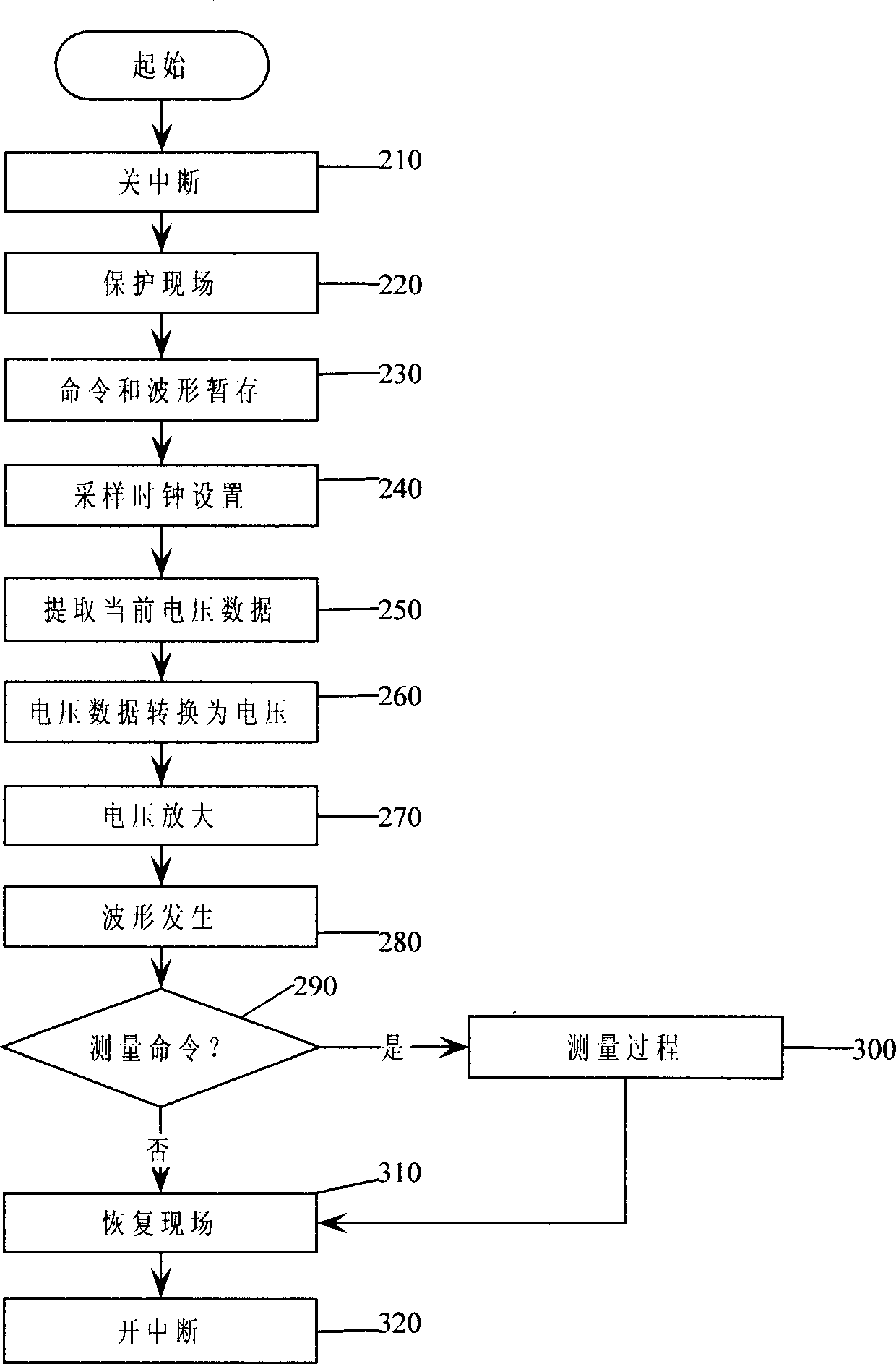

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

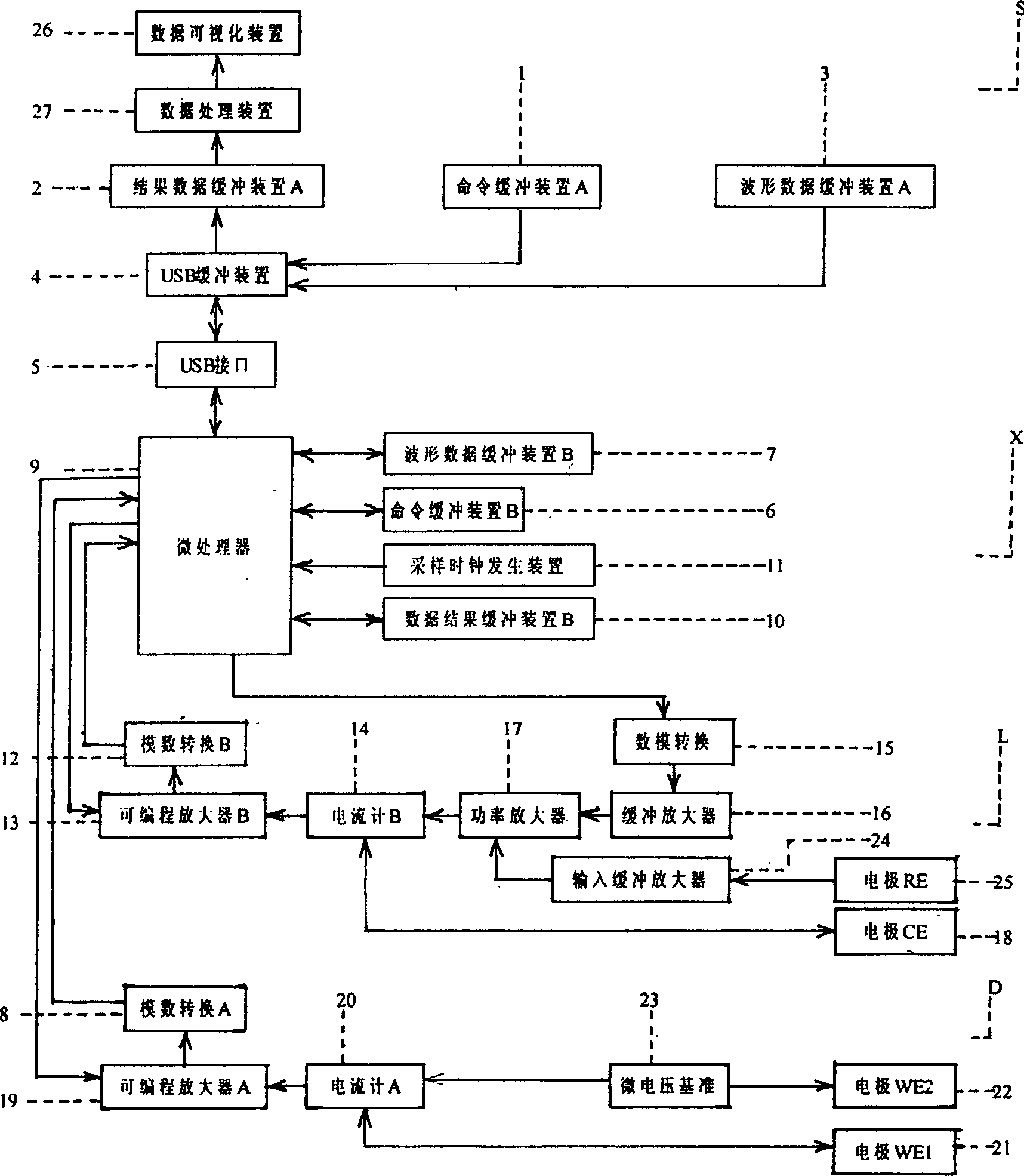

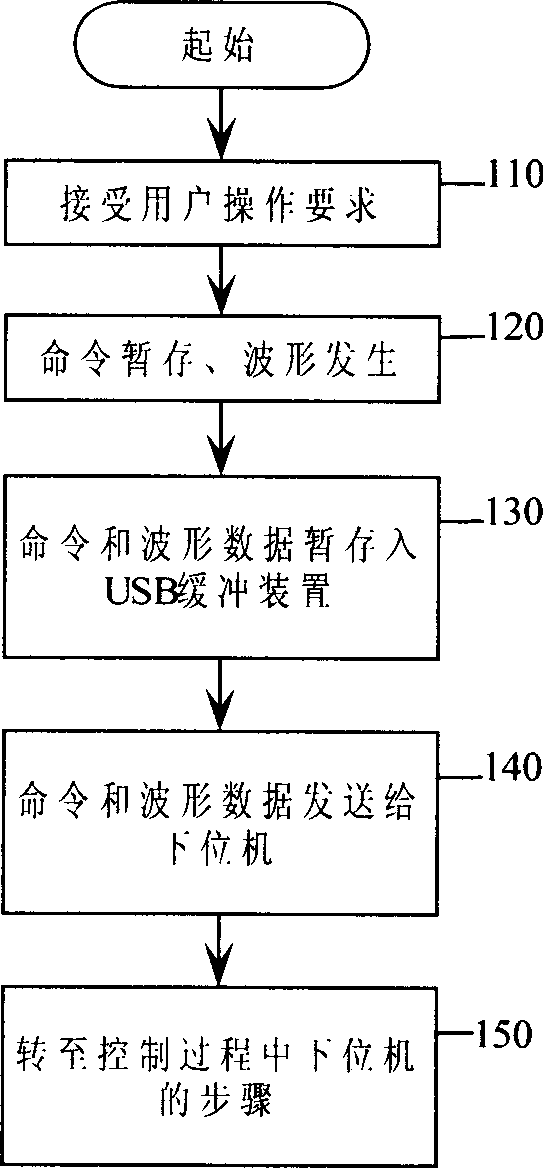

[0037] The upper computer unit S is a general-purpose personal computer. Part of the software programs of the present invention are stored and run in the computer constituting the upper computer unit S. Including command program, waveform data running program, result data running program, data processing running program, data visualization running program. Therefore, the corresponding upper computer unit S includes the following devices: a command buffer device A1 for storing commands, a waveform data buffer device A3 for storing waveform data, a result data buffer device A2 for storing result data, and a USB buffer device 4 , a data processing device 27 for storing data processing, and a data visualization device 26 for storing data visualization.

[0038] These devices of the upper computer unit S store and operate the result data receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com