Method for optimizing structure of shaft part based on immune genetic algorithm

A technology of immune genetic algorithm and shaft parts, applied in the field of mechanical design, can solve the problems of low precision and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

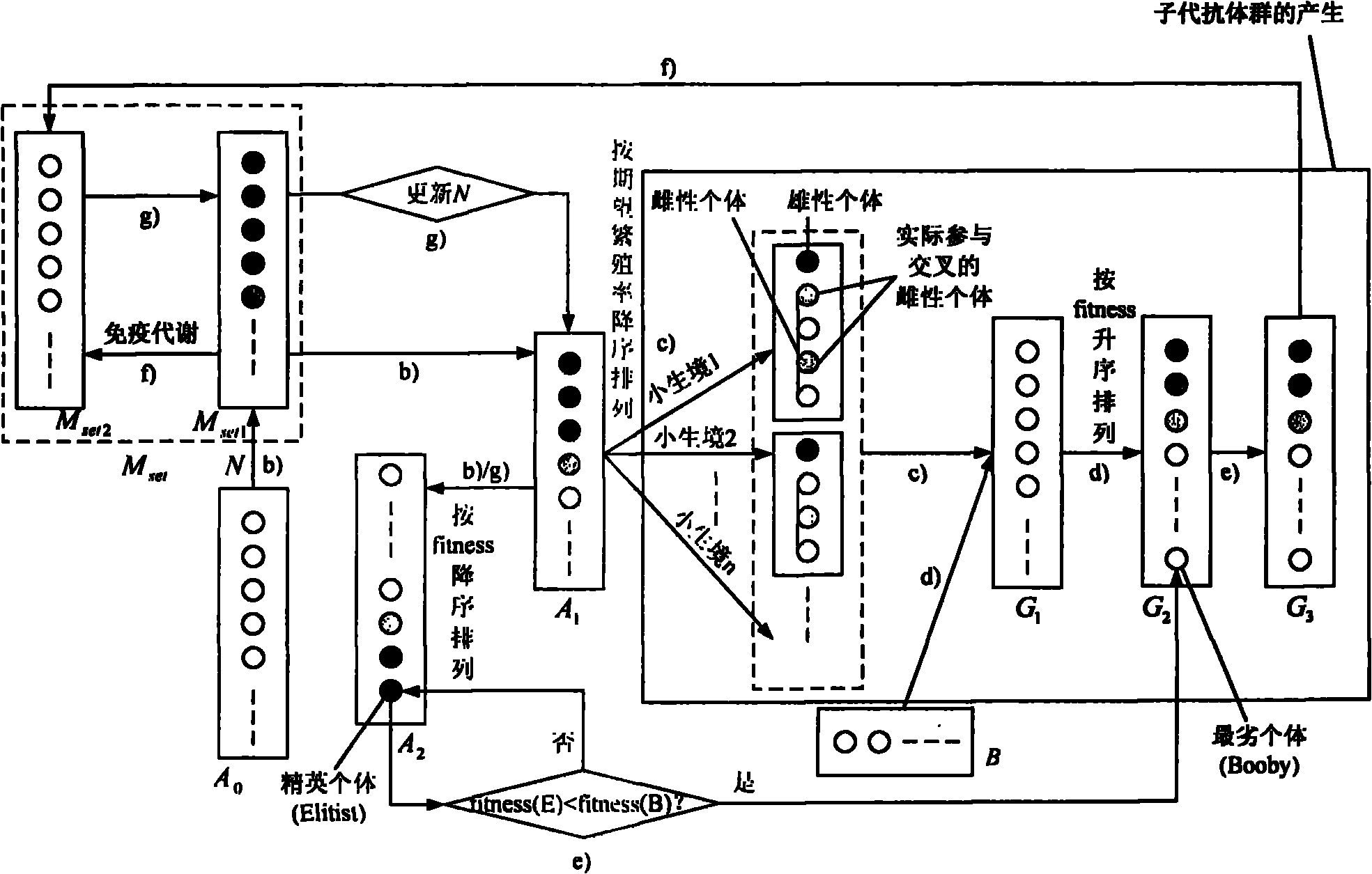

Method used

Image

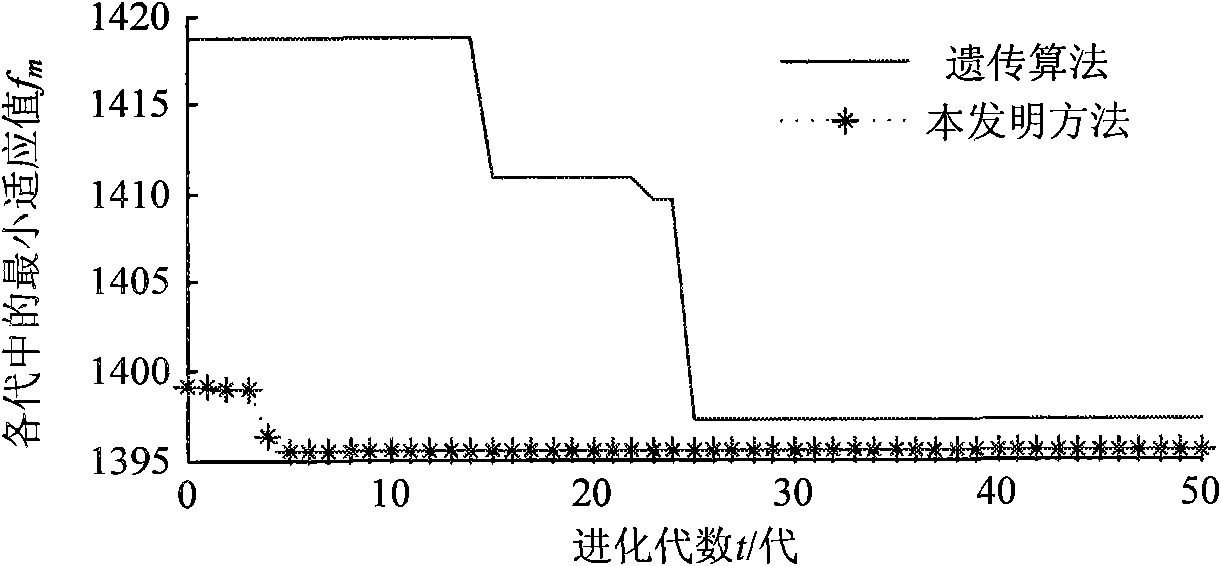

Examples

Embodiment

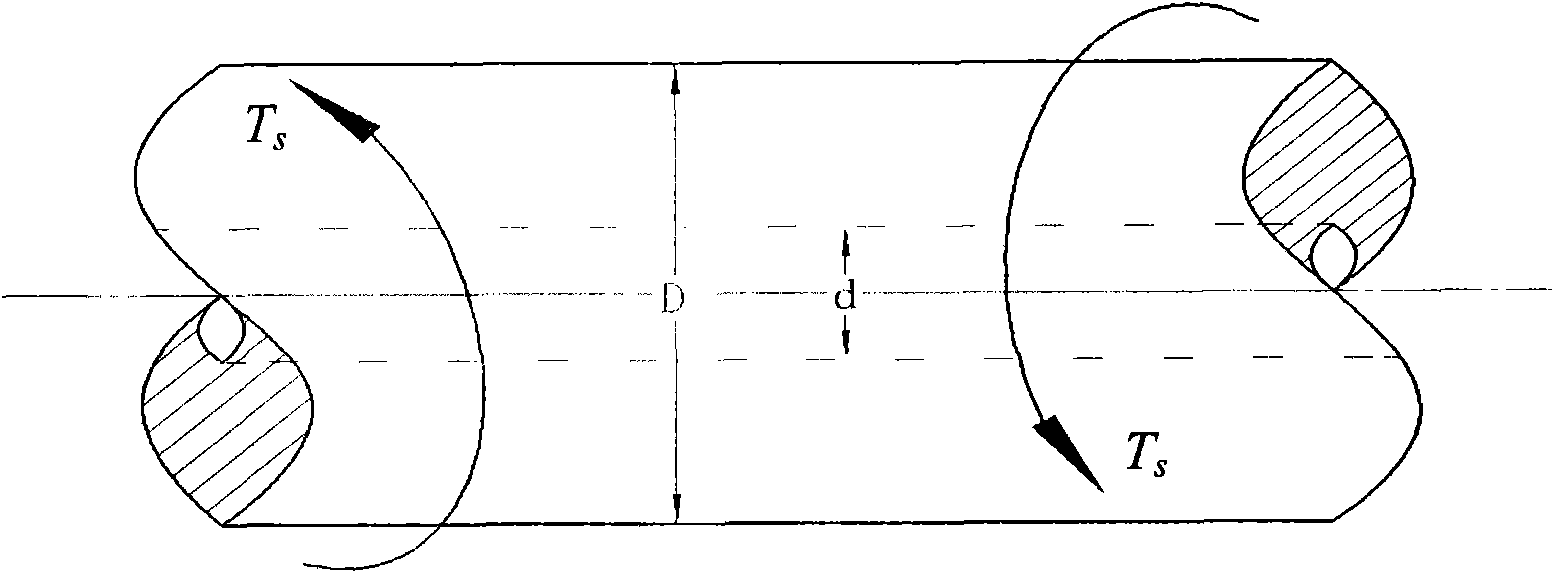

[0068] The three-stage planetary reducer of an earth pressure balance shield machine, the material used for the shaft is 17CrNi2MoAl, the three-stage shaft is hollow, the input torque is 1489N.m, the input speed is 1145.6rpm, the average value of the shaft shear strength and variance are 128Mpa and 16.64Mpa respectively, and its mechanical model is as follows figure 2 shown. In the three-stage planetary reducer, the torque of the upper-stage shaft is transmitted to the next-stage shaft through the spline, and the length of the three-stage shaft has been determined. The first to third-stage shafts are 120mm, 163mm and 241mm respectively, and their original basic dimensions The design parameters are:

[0069] The first stage shaft: the outer diameter is 63mm, the inner diameter is 15mm;

[0070] The second shaft: the outer diameter is 96mm, the inner diameter is 20mm;

[0071] Tertiary shaft: outer diameter is 117mm, inner diameter is 20mm.

[0072] The design requirement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com