Mould for molding magnetic core of soft ferrite

A soft ferrite and forming mold technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high labor intensity of workers, waste of raw materials, affecting product performance, etc., to save labor costs, reduce The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

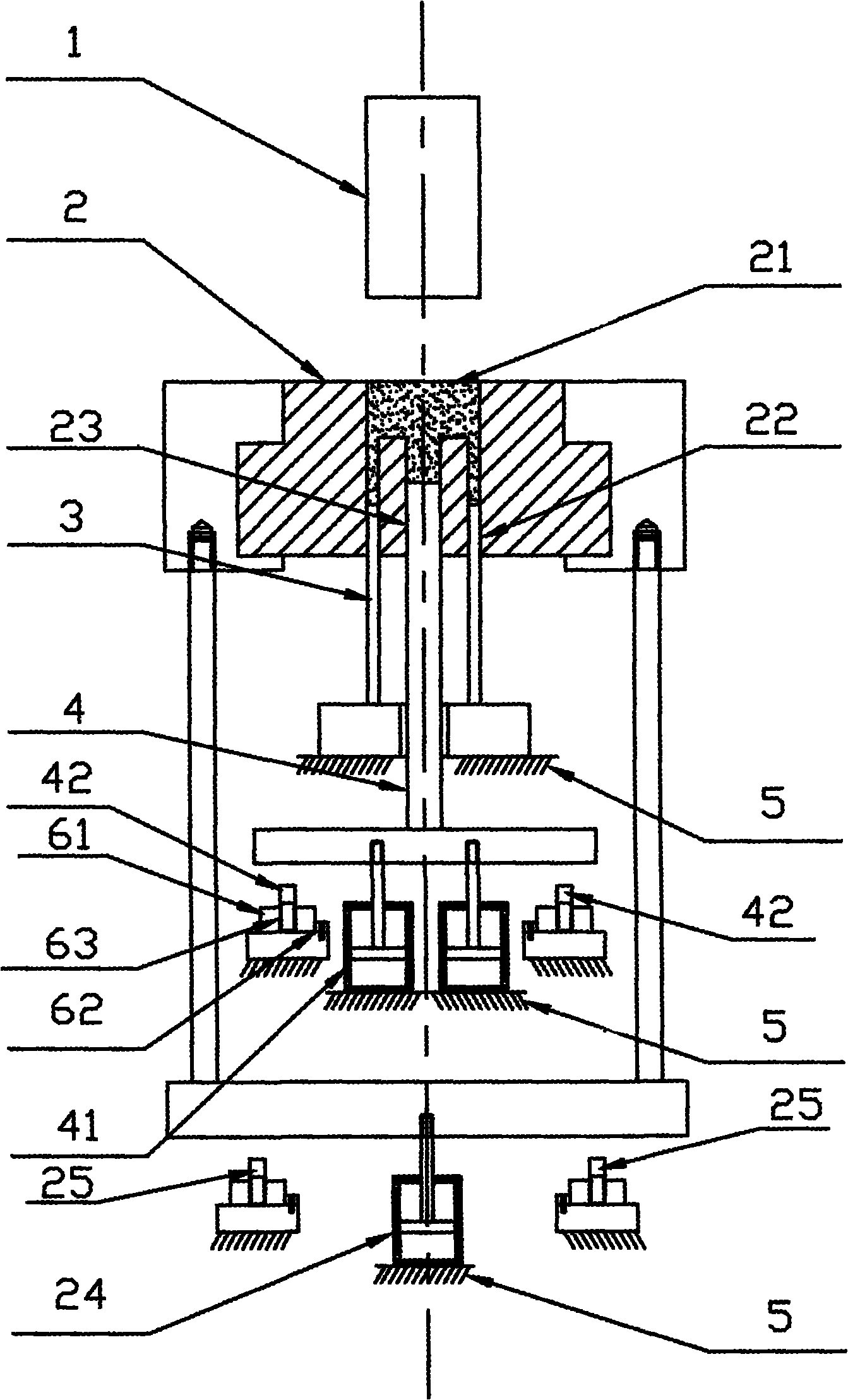

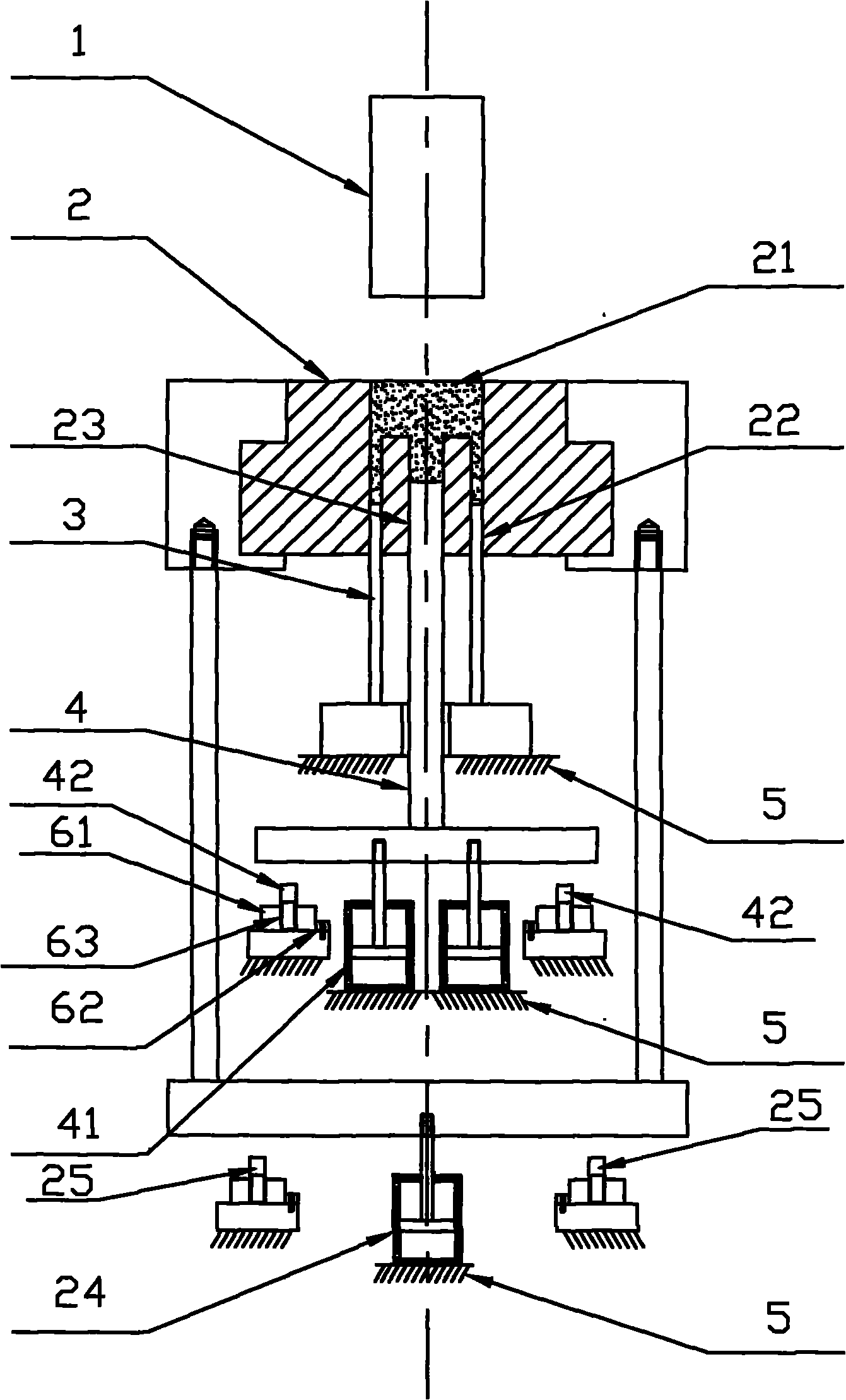

[0011] Embodiment: A mold for forming a soft ferrite core, including an upper punch 1, a middle die 2, a lower punch 3, a lower second punch 4, and a mold frame 5. Based on the direction of use, the middle die 2 can slide axially The set distance radial stop is positioned on the mold frame 5, the upper side of the middle mold 2 is provided with a forming groove 21, and the lower side of the middle mold 2 is respectively provided with the next punching hole 22 and the second punching hole 23. The upper end of the punching hole 22 and the lower two punching holes 23 communicate with the forming groove 21 of the middle mold 2, the lower end of the next punch 3 is fixed on the mold frame 5, and the upper end of the next punch 3 is axially slidable and inserted in the lower mold In the first punching hole 22, the lower end of the lower second punching 4 can slide axially at a set distance and the radial stopper is positioned on the mold base 5, and the upper end of the lower second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com