Rotating handle operating device of moulded case circuit breaker

A molded case circuit breaker and rotary handle technology, which is applied in the direction of protection switch operation/release mechanism, etc., can solve problems such as difficult installation and debugging, seizure, inflexible transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

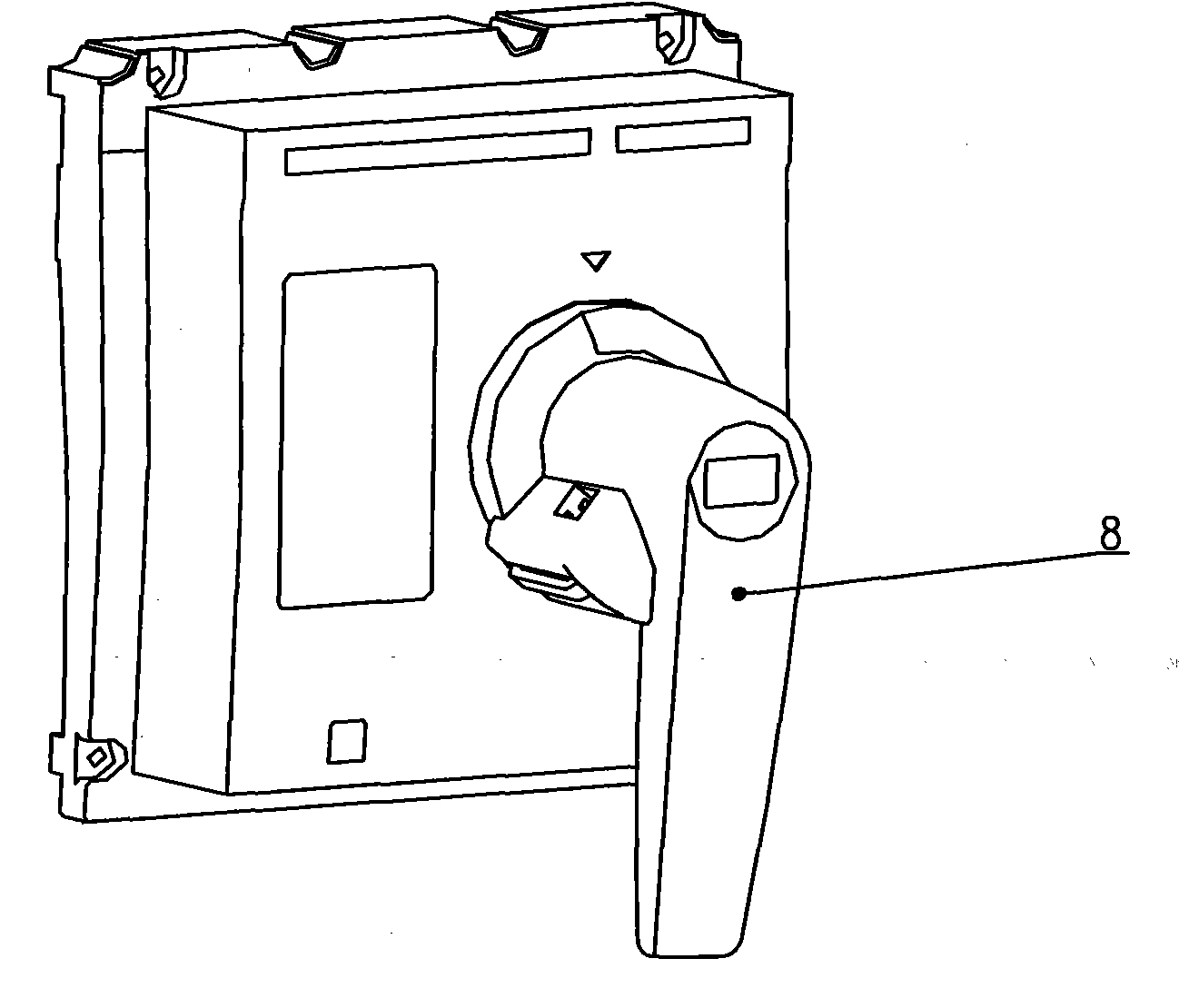

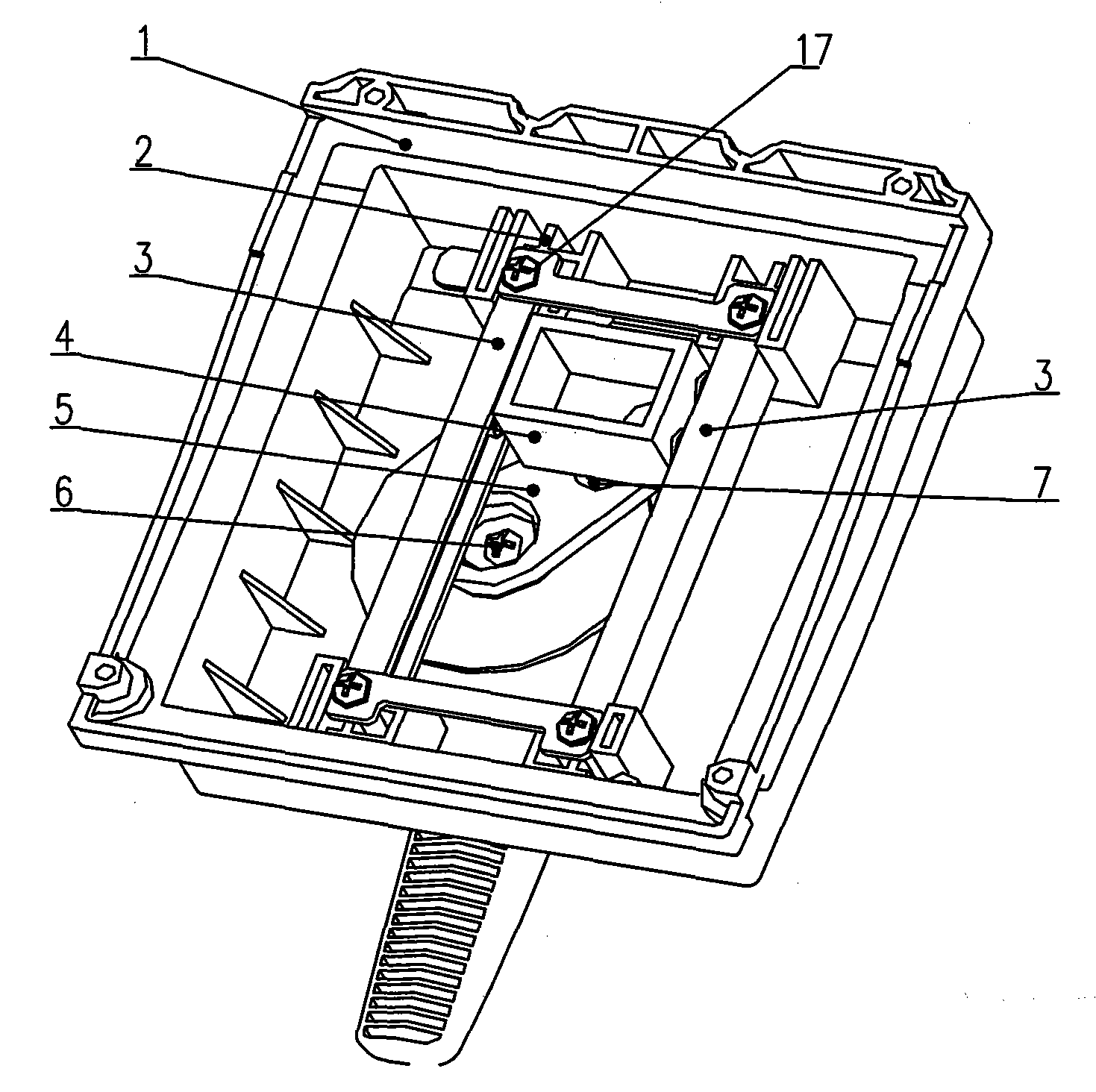

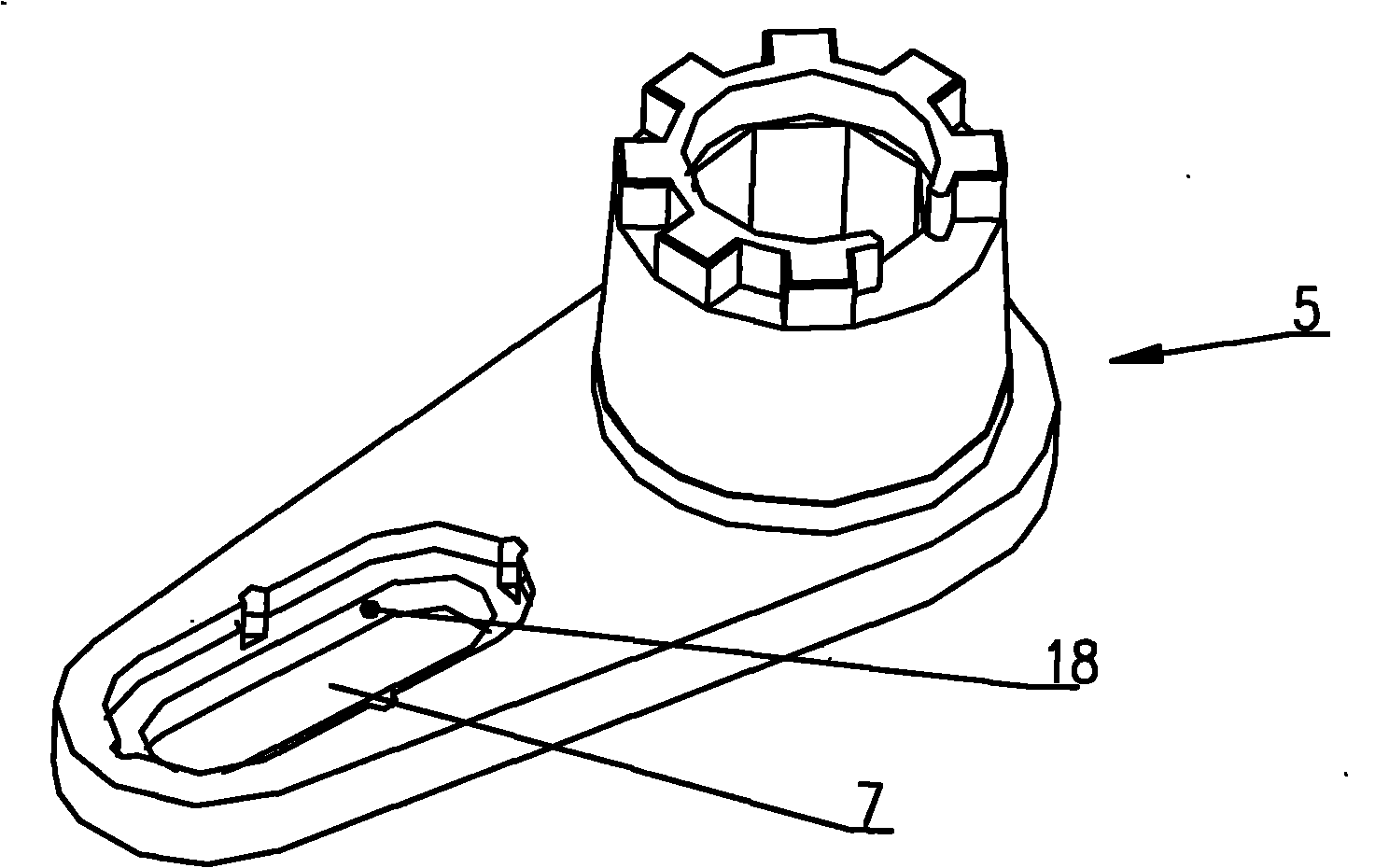

[0017] attached Figures 1 to 5 What is shown is an embodiment of the rotary handle operating device of the molded case circuit breaker of the present invention, and the rotary handle operating device of the molded case circuit breaker of the present invention is not limited to this embodiment.

[0018] Such as Figures 1 to 5 As shown, the rotary handle operating device of the molded case circuit breaker of the present invention includes a cover 1, a rotary handle 8, a rocker arm 5, a guide plate 4 with a socket 11, a guide rail 3 and four A guide mechanism composed of a support shaft 9 and four bearings 10, a toggle mechanism composed of a chute 7, a toggle shaft 12 and a first rolling bearing 13, the cover 1 and the molded case circuit breaker (not shown in the figure) ) can be fixed directly. After the cover plate 1 of the rotary handle operating device of the present invention is installed and fixed on the molded case circuit breaker, the handle (not shown in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com