Composition for resin and optical lens obtained therefrom

一种组合物、树脂的技术,应用在光学、光学元件、光学部件等方向,能够解决组合物粘度升高、材料色调变差、浇铸聚合操作困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

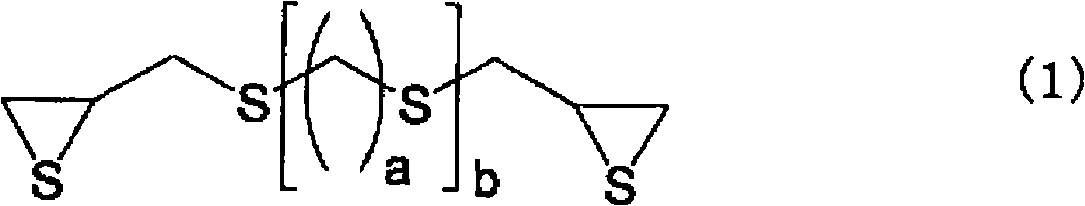

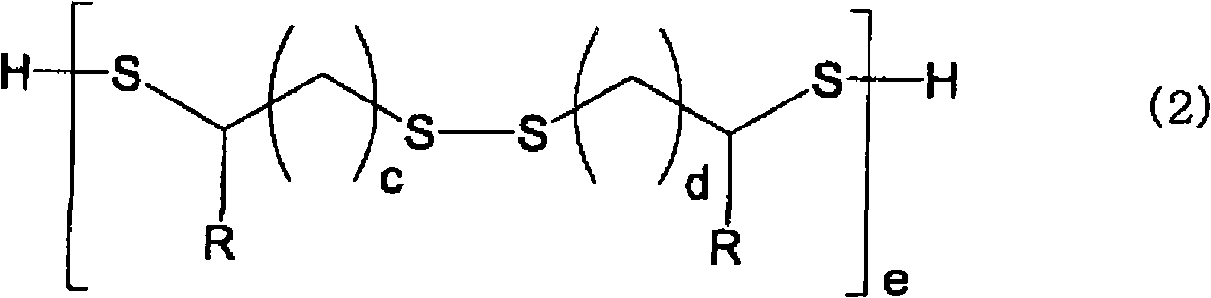

[0168] At 50°C, 29 parts by weight of sulfur as compound (a) (hereinafter referred to as "compound a-1"), and 71 parts by weight of bis(β-epithiopropyl) sulfide as compound (b) (hereinafter referred to as referred to as "compound b-1"), and 14 parts by weight of bis(mercaptomethyl)disulfide (hereinafter referred to as "compound c-1") as compound (c) were thoroughly mixed until uniform. Next, 0.15 parts by weight of 2-mercapto-1-methylimidazole was added as a prepolymerization catalyst, and the prepolymerization was carried out while fully stirring at 50°C until no sulfur was precipitated even after cooling to 30°C. The time required for the reaction was 30 minutes. Thereafter, at 30° C., 1 part by weight of compound c-1 (15 parts by weight in total), 0.03 parts by weight of tetrabutylphosphonium bromide as compound (d), 0.1 parts by weight of 1 part of di-n-butyltin dichloride as compound (e), mixed thoroughly to form a homogeneous mixture. This mixture was degassed at 100 T...

Embodiment 2

[0171] Example 1 was repeated except that the added compound c-1 was changed from 14 parts by weight to 19 parts by weight. Table 1 shows the evaluation results of the viscosity of the resin composition after the degassing treatment and after 2 hours, the refractive index and Abbe number of the obtained optical material, heat resistance, and color tone.

Embodiment 3~14

[0187] In Example 1, compound a-1, compound b-1 and compound c-1 were changed to the compounds shown in the following table 2, and the addition amount of each compound was changed to the amount shown in the following table 2, Other than that, the resin composition was prepared in the same manner as in Example 1, the viscosity of the resin composition after the degassing treatment and after 2 hours, the refractive index and Abbe number of the obtained optical material, heat resistance, and color tone The evaluation of was carried out in the same manner as in Example 1.

[0188] Table 2

[0189]

[0190] According to the present invention, since the viscosity of the resin composition containing an inorganic compound having a sulfur atom and / or a selenium atom can be reduced, the casting polymerization operation including the filtration step becomes easy, and the color tone of the obtained optical material becomes good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com