A liquefied gas tank with a central hub in the bottom structure

A liquefied gas, structural beam technology, applied in gas processing applications, fixed-capacity gas storage tanks, outer walls of container structures, etc., to achieve the effect of convenient disassembly, easy installation, and avoidance of shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

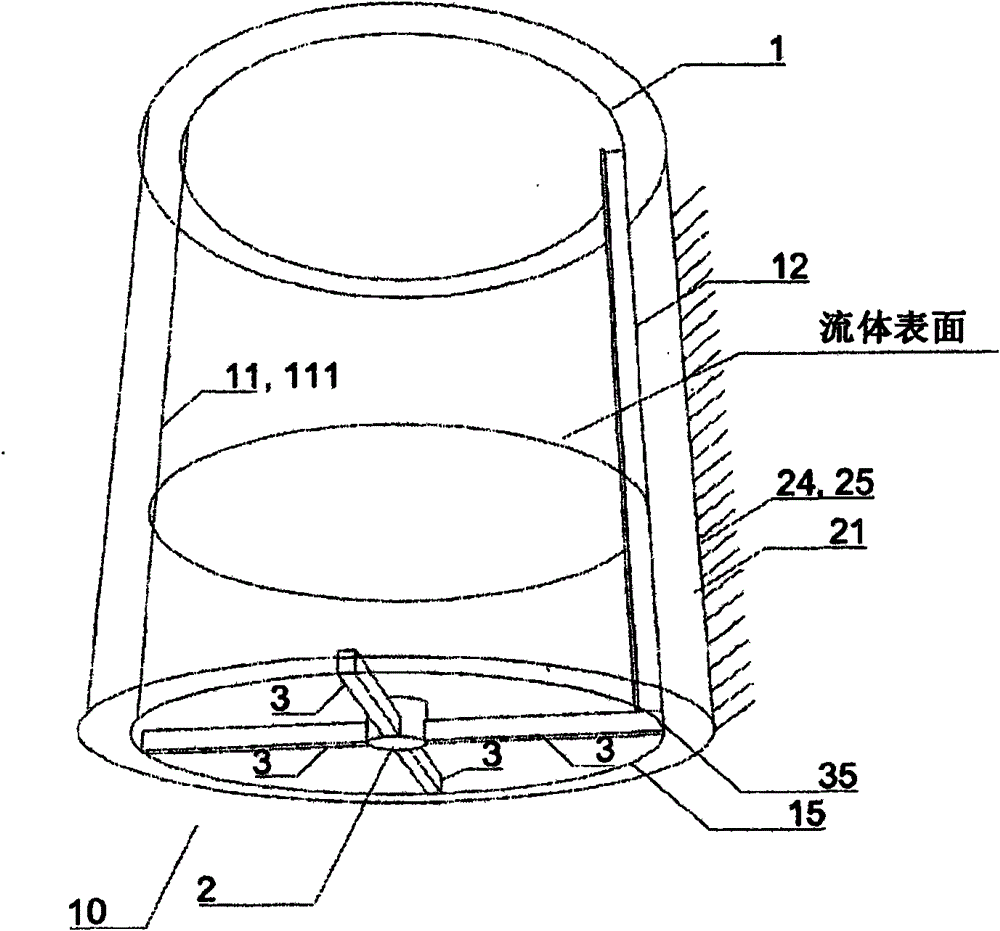

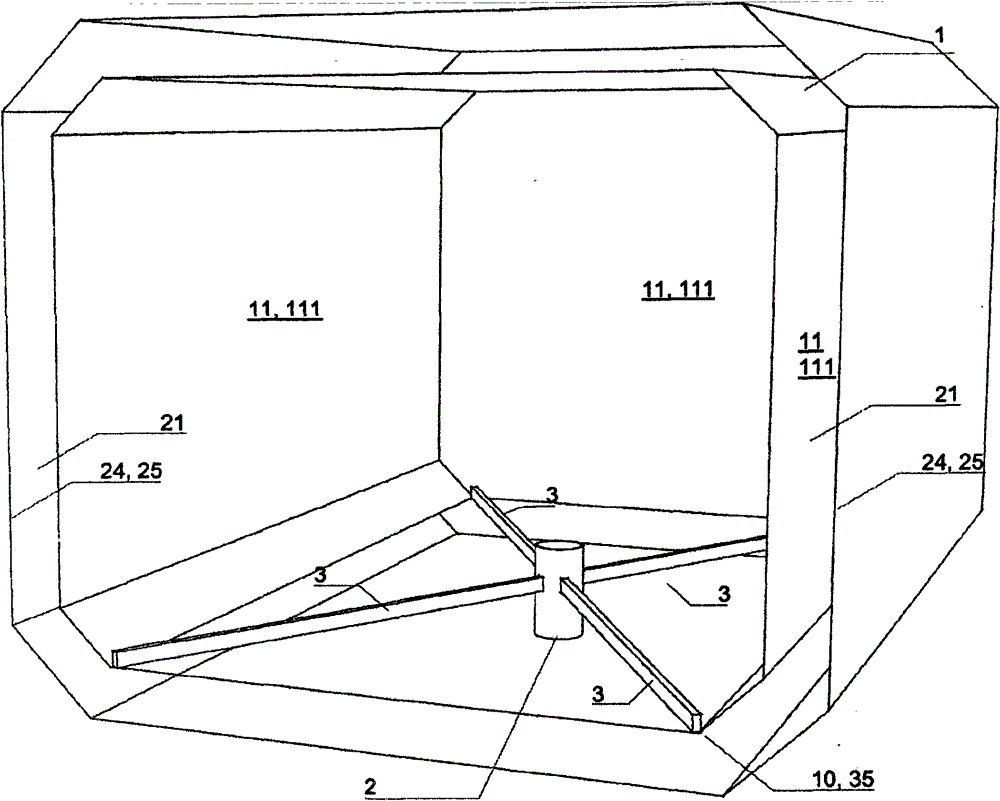

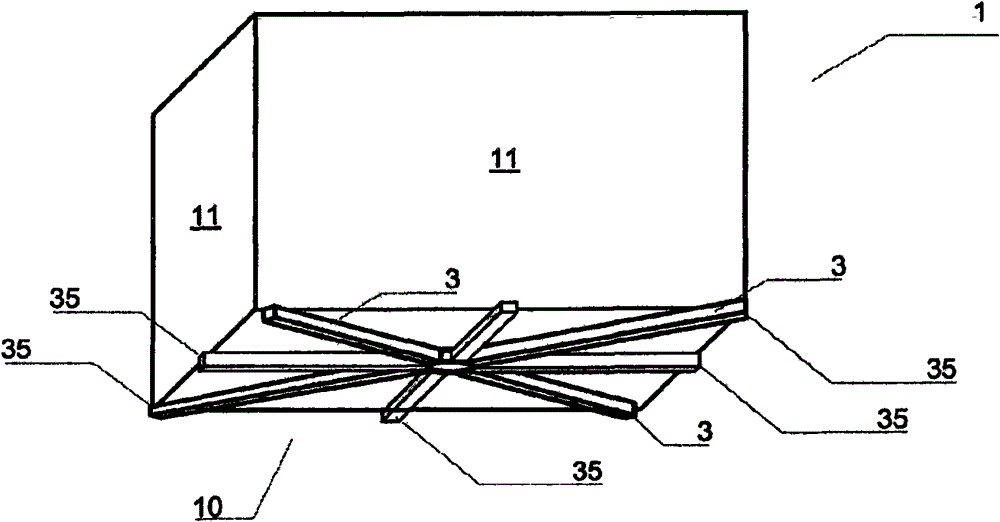

[0052] The invention comprises a tank 1 for liquefied gases such as liquefied methane (LNG), liquefied ethane, liquefied propane (LPG) or other liquefied gases. The tank 1 according to the invention is used in a ship or other marine vessel. The term "ship" or "marine vessel" as used in this specification also includes floating and semisubmersible petroleum production or storage vessels. Furthermore, the tank according to the invention can be arranged on a stationary ship structure. The tanks described are designed for use at atmospheric pressure, but pressurized tanks are also contemplated. The tank according to the invention is generally referred to below as cryogenic tank 1 , but the invention is not limited to tanks in the cryogenic range, but for liquefied gases such as the gases mentioned above. The tank 1 for liquefied gas is provided with a tank bottom structure 10 and a tank wall structure 11 which is arranged around a periphery 15 of said tank bottom structure 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com