Solar cell manufacturing method, solar cell manufacturing device, and solar cell

A technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve problems such as damage, and achieve the effect of repairing defective parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the manufacturing method of the solar cell according to the present invention, and the manufacturing apparatus of the solar cell of the present invention used for the method will be described with reference to the accompanying drawings. In addition, the present embodiment is specifically described for better understanding of the gist of the invention, and is not intended to limit the present invention unless otherwise specified.

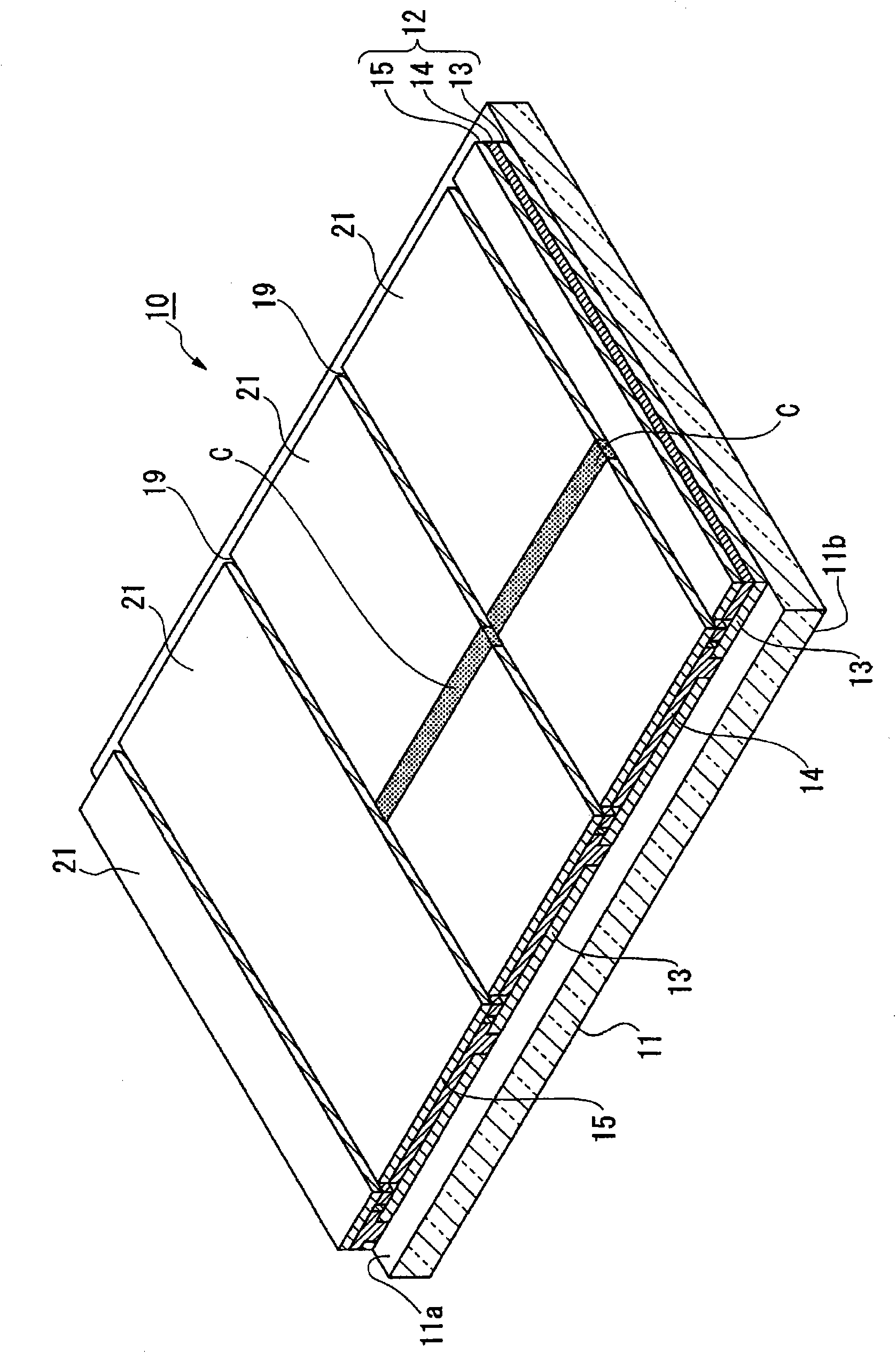

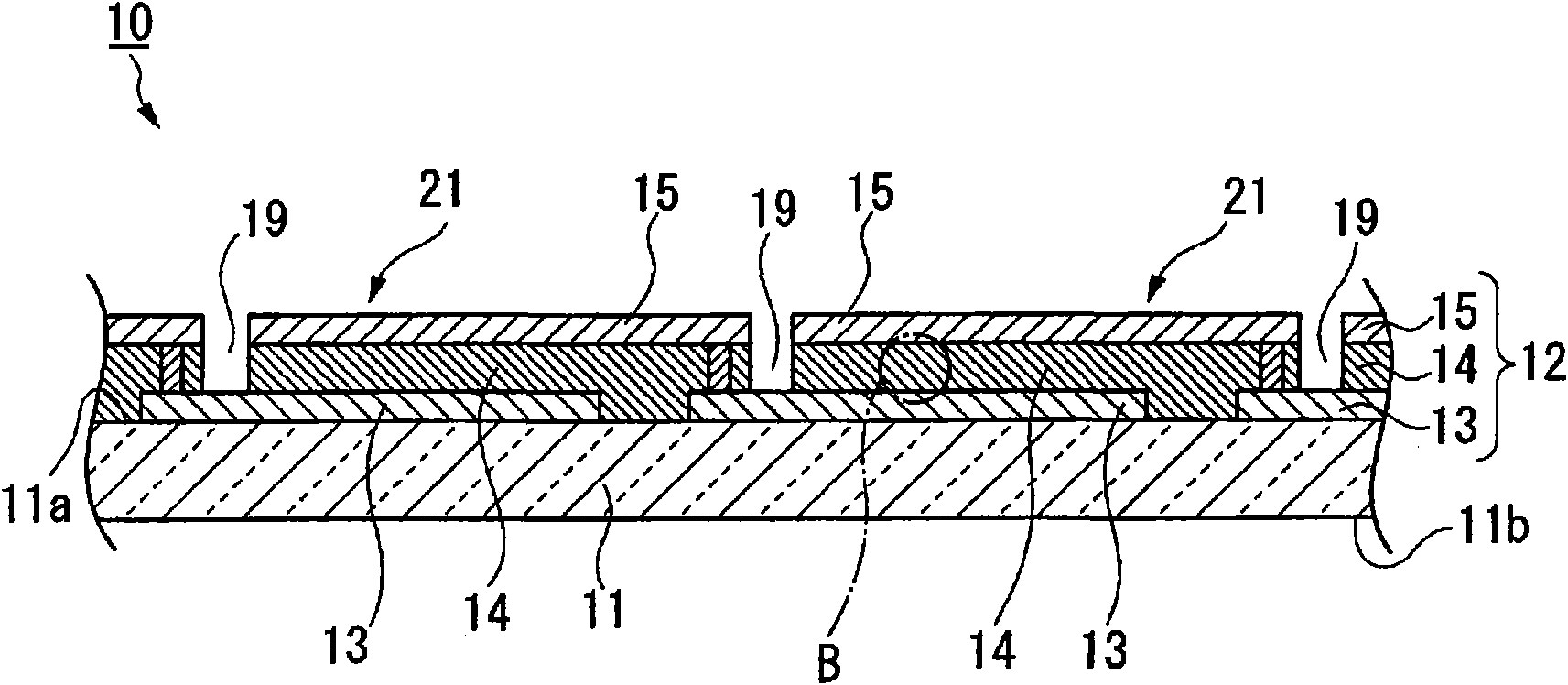

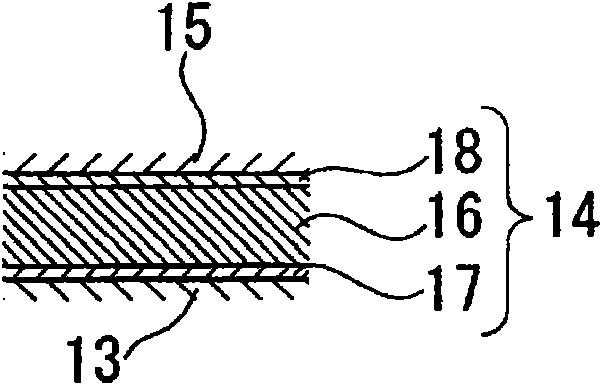

[0051] figure 1 It is an enlarged perspective view showing an example of a main part of an amorphous silicon type solar cell manufactured by the manufacturing method of the solar cell of the present invention. In addition, FIG. 2(a) shows figure 1 Cross-sectional view of the layer structure of a solar cell. Fig. 2(b) is an enlarged cross-sectional view of the portion indicated by reference numeral B in Fig. 2(a) . The solar cell 10 has the photoelectric converter 12 formed on the first surface 11 a (one surface) of the transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com