External window construction technology for assembling external window steel subframe by plastic-steel connection corner

A construction process and technology of steel sub-frame, applied in the direction of window/door frame, window/door, frame fixing, etc., can solve the problems of low processing and installation efficiency, difficult to control welding size, easy to rust door and window installation connection strength, etc. Conducive to construction site management, control cost and resource loss, and eliminate the effect of poor anti-corrosion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing.

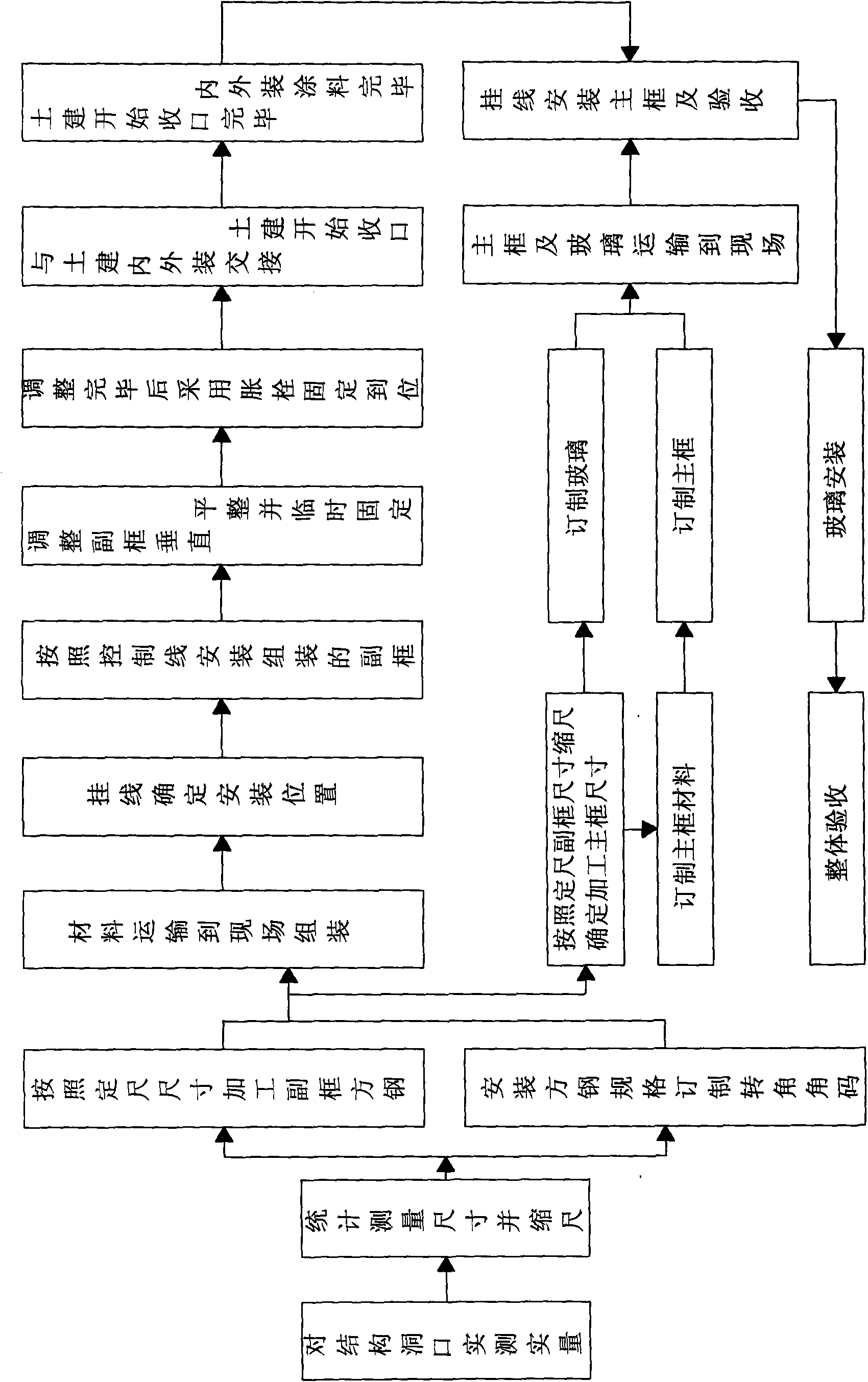

[0024] see figure 1 , the construction process of the outer window of the present invention to assemble the outer window steel sub-frame of the plastic steel connection angle code, carry out according to the following steps:

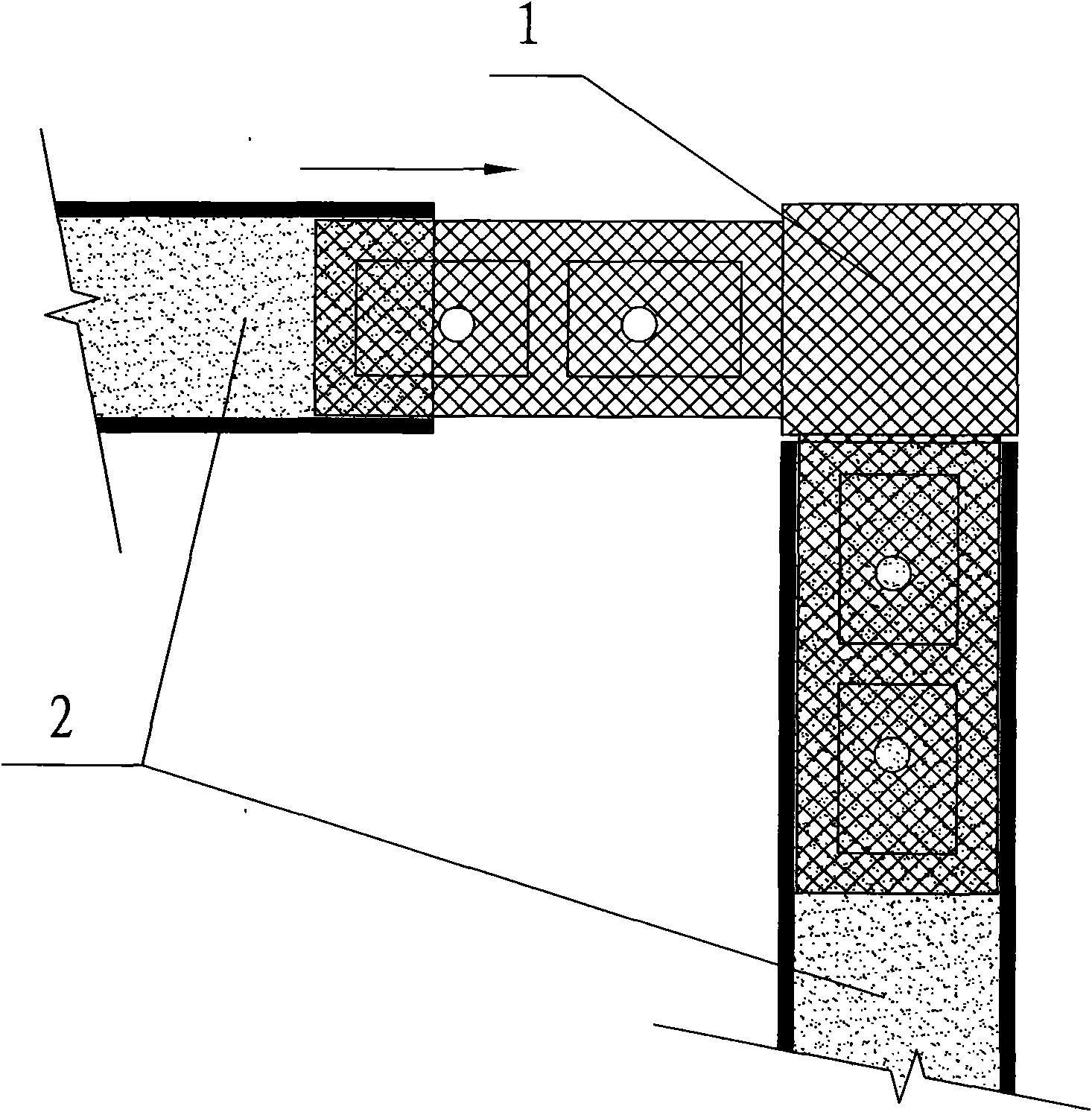

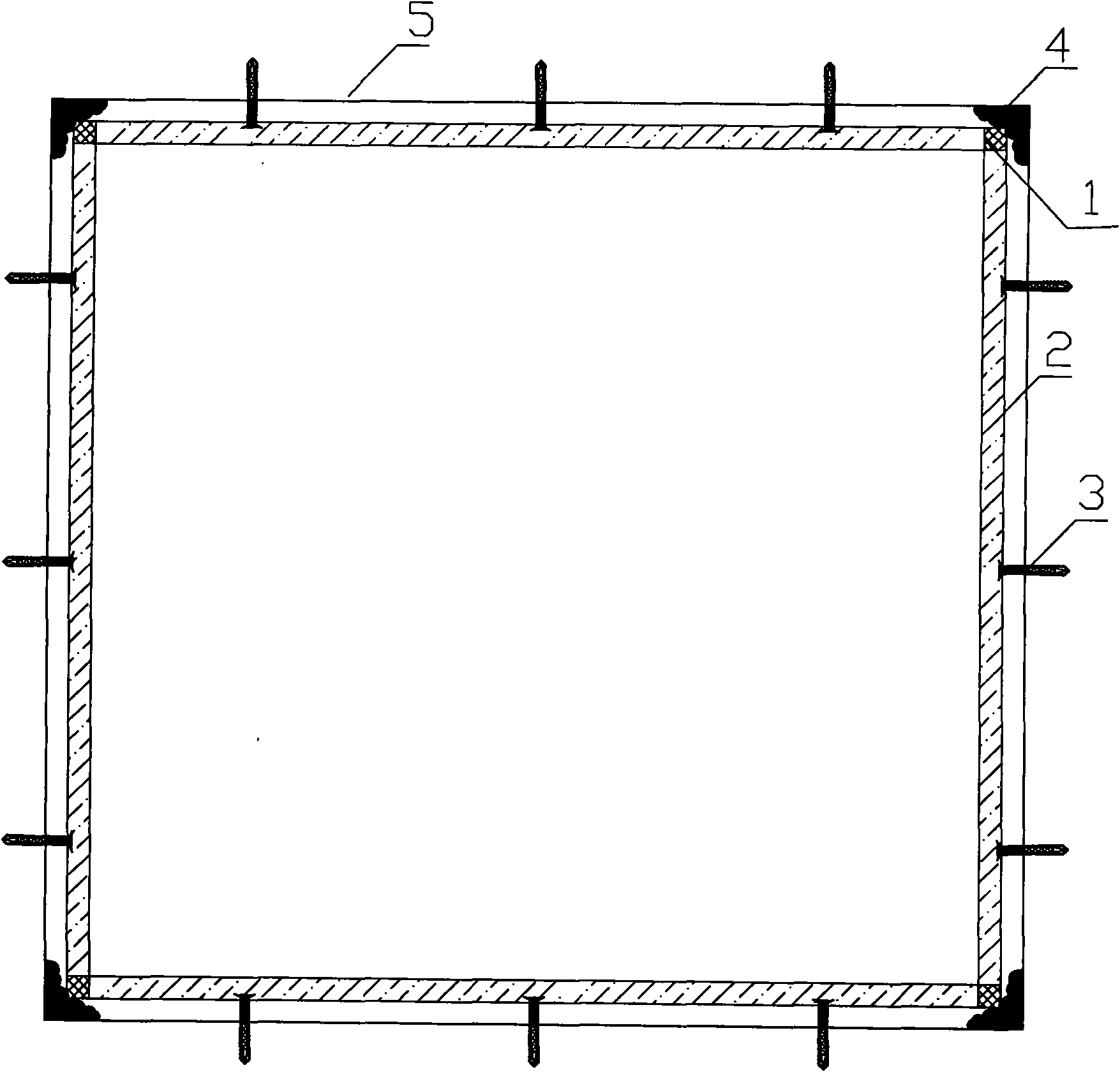

[0025] (1) After the construction of the main structure is completed, the opening of the structure is handed over to the external window manufacturer for actual measurement and measurement, and the processing size of the sub-frame material is determined according to the design requirements of the opening and the scaling requirements of the sub-frame of the external window. All kinds of forms are prepared according to the design model and actual measured size scale, and the material list is proposed. The sub-frame processing workshop cuts the galvanized square steel into galvanized sub-frame frame square steel 2 according to the blanking list, and opens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com