Method for detecting color difference of printed matter

A detection method and technology for printed matter, applied in the field of printing industry, can solve the problem that the detection data cannot accurately detect the color difference quality of the printed matter, and achieve the effect of increasing the added value of the product, improving the quality of the product and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

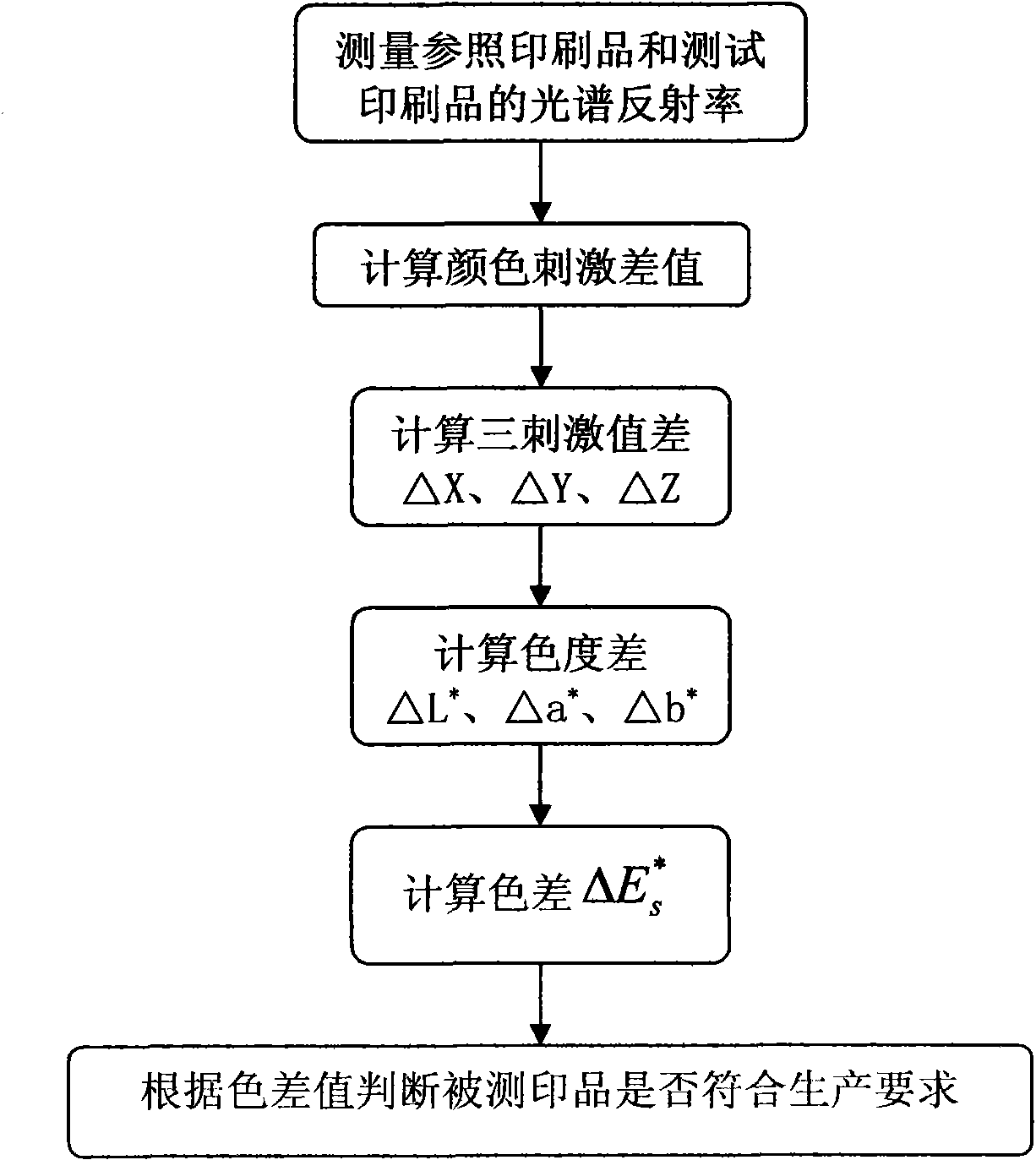

Method used

Image

Examples

Embodiment 1

[0056] Utilize the inventive method to calculate the color difference of certain test print and reference print under D65 light source, 2 ° field of view conditions, to judge whether the color of test print is qualified:

[0057] step 1,

[0058] Use the X-Rite SpectroEye spectrophotometer to measure the spectral reflectance ρ of the reference prints respectively 1 (λ) and the spectral reflectance ρ of the test print 2 (λ); the wavelength interval Δλ is 10nm, and the measured wavelength λ range is 380nm to 730nm; as shown in Table 1:

[0059] Table 1 Spectral reflectance of reference prints and test prints

[0060]

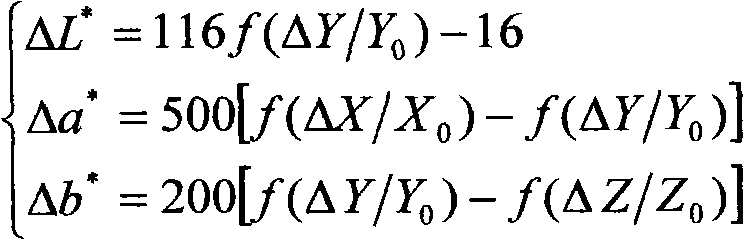

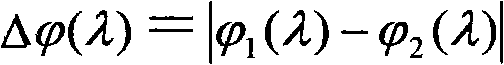

[0061] Step 2, calculate the color stimulus difference between the reference print and the test print:

[0062]

[0063] in, In order to refer to the color stimulus value of the printed matter, To test the color stimulus value of printed matter, S(λ) is the relative spectral power distribution determined according to the D65 light source, as shown i...

Embodiment 2

[0092] The Munsell system, as an internationally common uniform color system, has been widely used in the study of uniform color space, color difference, and color appearance. X-Rite SpectroEye spectrophotometer was used to measure the spectral values of 1325 color samples in the Munsell Atlas, and the spectral measurement range was 380nm-730nm with an interval of 10nm. Among these color samples, 960 color pairs with a hue difference of 2.5, 961 color pairs with a lightness difference of 1, and 961 color pairs with a chroma difference of 2 were selected, totaling 2882 pairs. Convert hue difference, lightness difference and chroma difference into visual Difference.

[0093] Standard residual sum of squares index (STRESS, standardized residual sum of squares index) is used to evaluate the performance comparison between the method of the present invention and CIELAB, CMC, CIEDE2000 color difference formula.

[0094] The STRESS method is shown in the following formula:

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com