Guide column guiding mechanism capable of adjusting taper

A guide mechanism and guide post technology, applied in the field of presses, can solve the problems of enlarged gap between the guide post and the guide sleeve, roughening, poor precision, etc., and achieve the effects of saving maintenance costs, convenient disassembly and adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

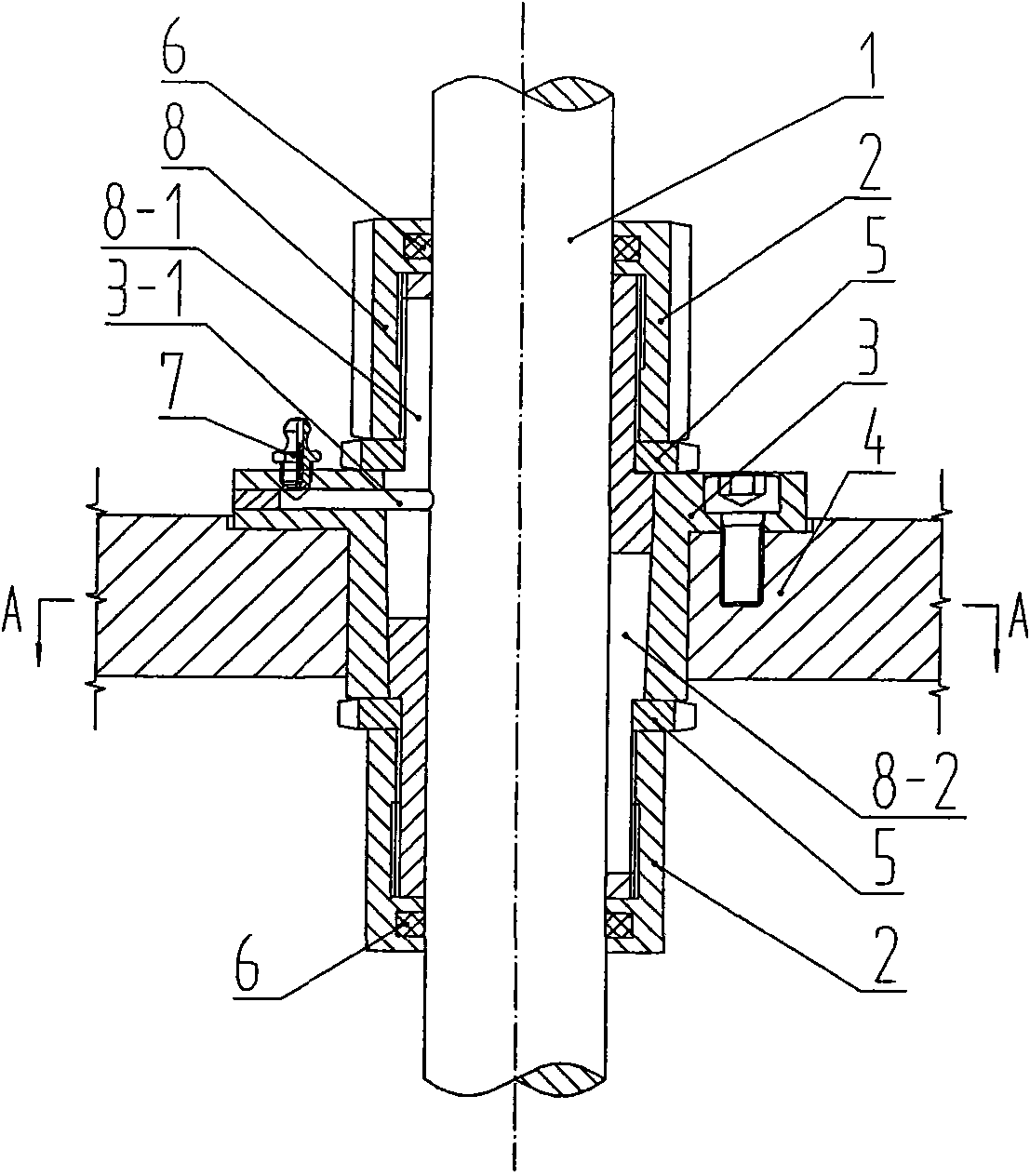

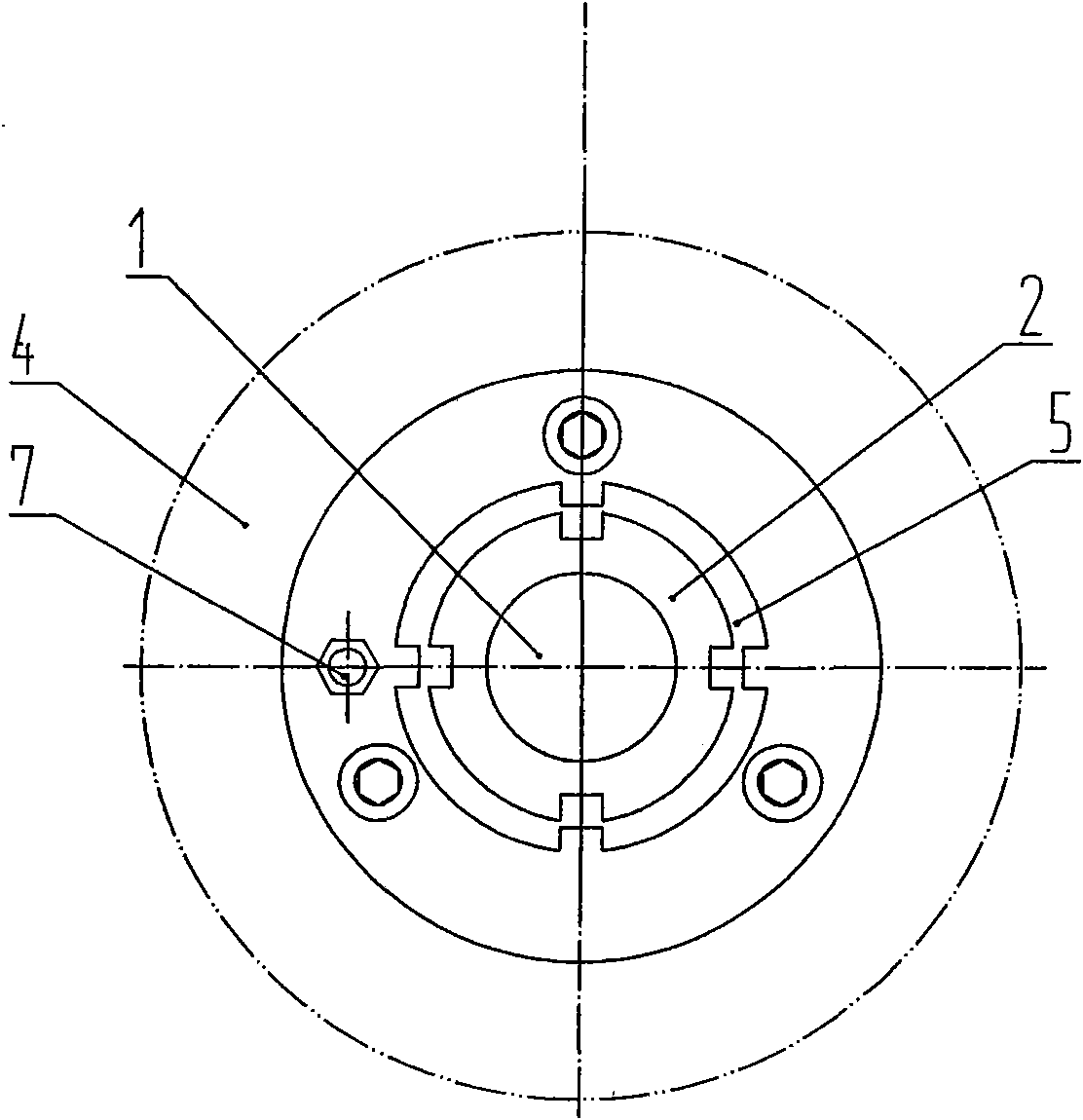

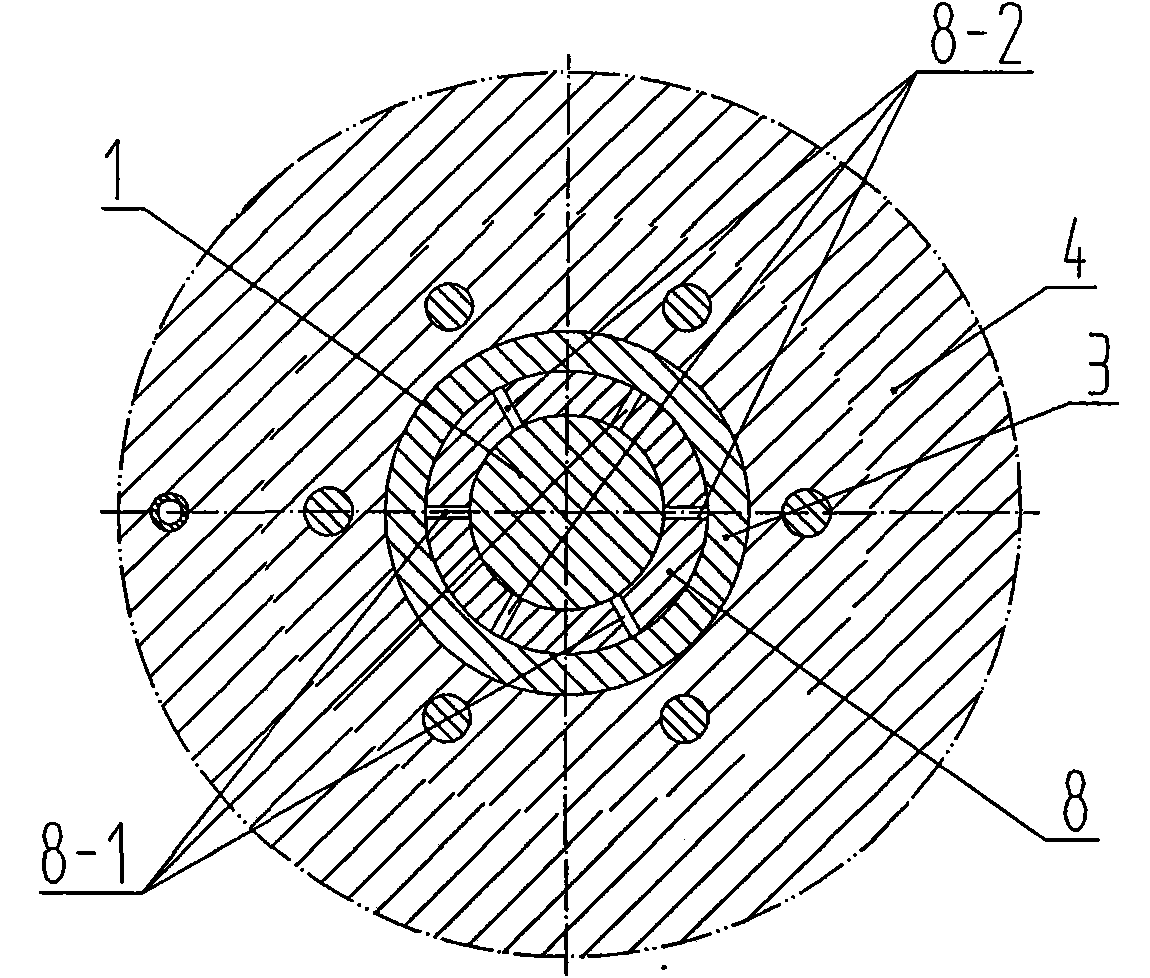

[0016] Such as figure 1 , 2 , shown in 3: a guide post guide mechanism with adjustable taper, including a guide post 1 and a guide sleeve sleeved on the guide post 1; it is characterized in that: the guide sleeve includes: a fixed sleeve 3, a taper sleeve 8 and Large nut 2 and round nut 5 for adjusting the upper and lower displacement of the tapered sleeve; the fixed sleeve 3 is a tubular body with a flange, the flange part of which is fixed on the fuselage 4 by bolts, and the inner hole of the fixed sleeve 3 is a conical hole; the inner hole of the tapered sleeve 8 is slidingly fitted with the guide post 1, and the outer circle of the tapered sleeve 8 is divided into three sections: the middle section is a conical shape matched with the conical hole of the fixed sleeve 3, and is connected with the inner cone of the fixed sleeve 3 The holes are connected by sliding fit; the upper and lower sections of the taper sleeve 8 are external threads, and the large nut 2 and the round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com