Drag reducing cover body installed on tail of coach body of van or container cargo truck

A van and container technology, which is applied to vehicle parts, body, streamlined body, etc., can solve the problem of inability to reduce the resistance of the rear of the van or container freight truck, so as to reduce energy dissipation, reduce area, Reduce the effect of turbulent separation zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

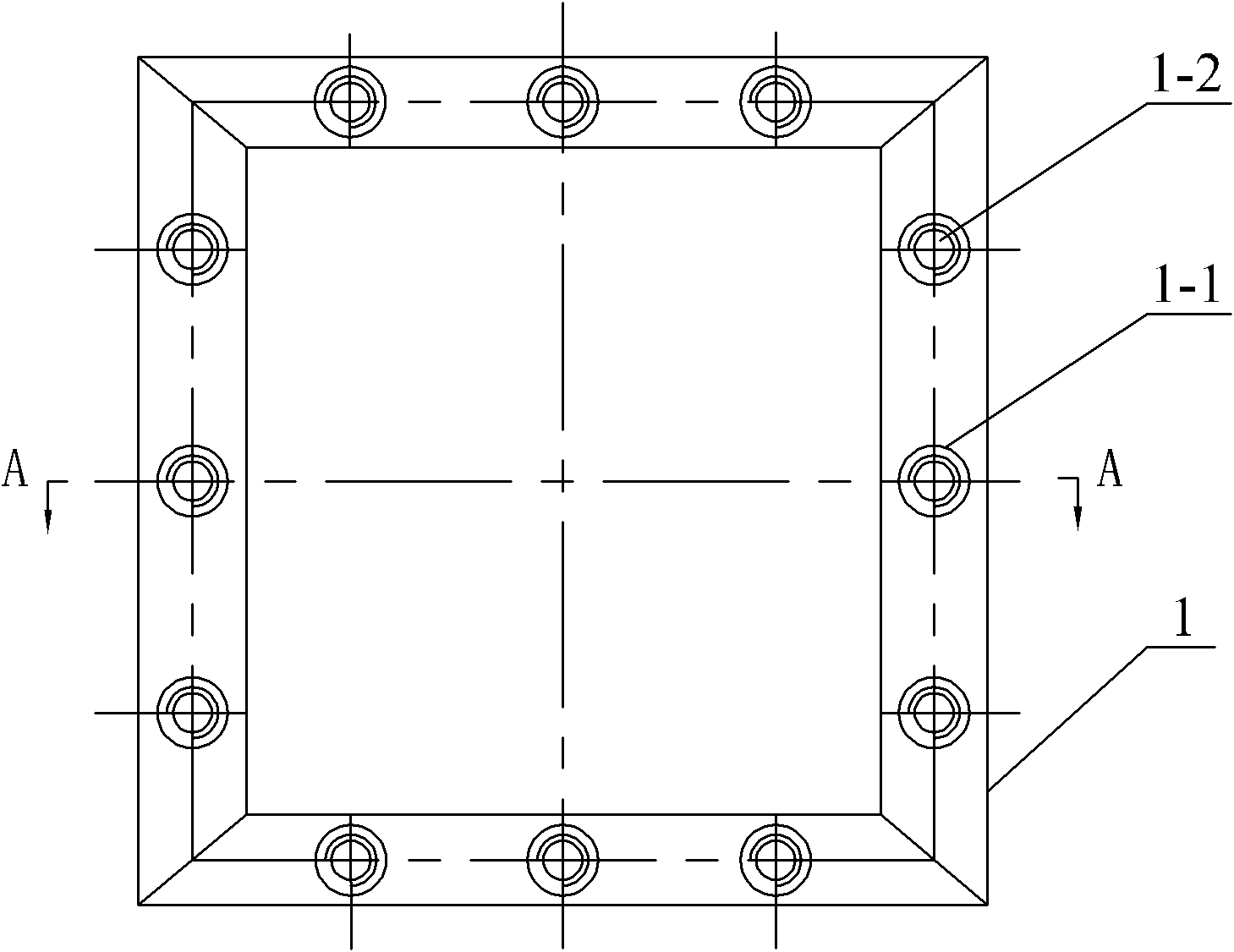

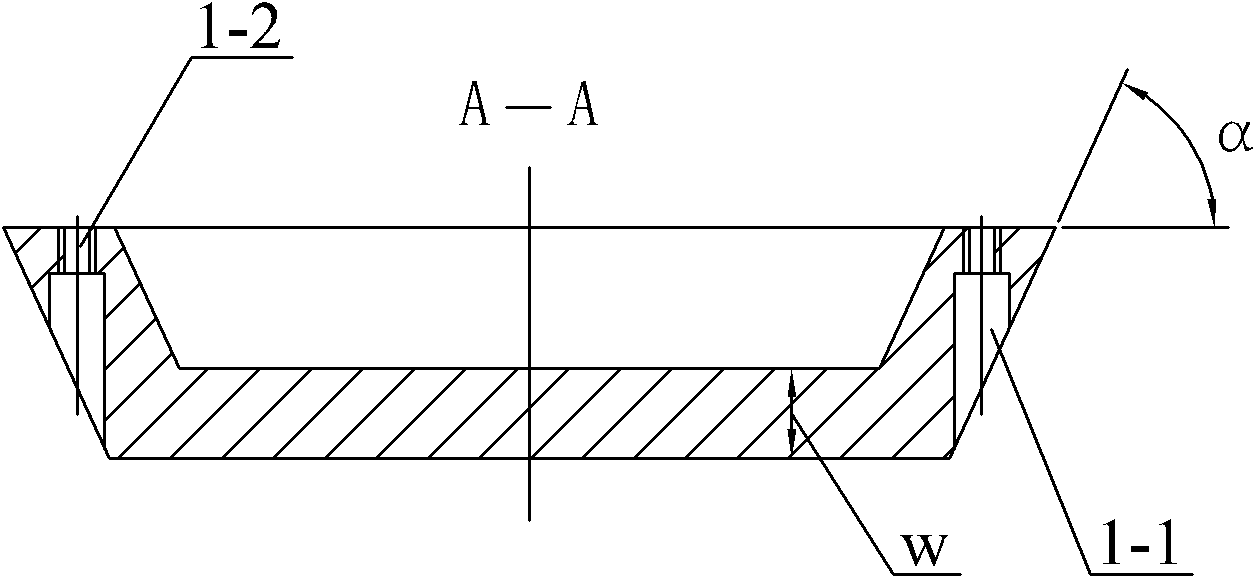

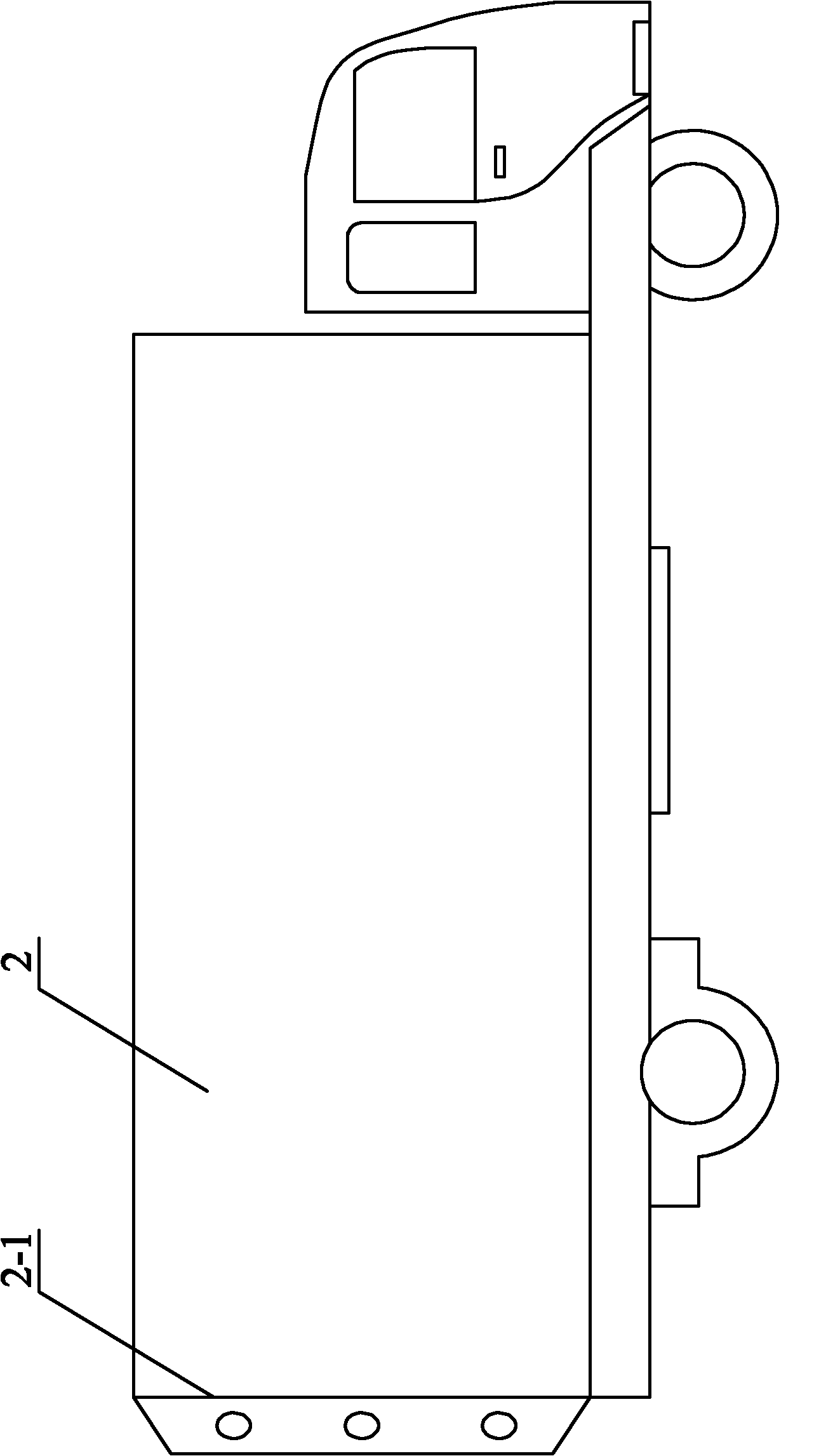

[0008] Specific implementation mode one: combine Figure 1-Figure 4 Description, the external shape of the drag reducing cover 1 described in the present embodiment is a quadrangular truss, the wall thickness w of the quadrangular truss drag reducing cover is 5mm-10mm, the inclined surface of the quadrangular truss drag reducing cover and the quadrangular truss reducing The included angle α between the large end surfaces of the resistance cover body is 50°-80°, and the large end surface of the four-sided platform drag reduction cover body is attached to the rear end surface 2-1 of the box body of the van or container freight truck 2, The four-sided platform drag-reducing cover is detachably connected to the box body tail end surface 2-1 of the van or container freight truck 2.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination image 3 and Figure 4 It is illustrated that the outer periphery of the large end surface of the quadrangular truss drag-reducing cover in this embodiment coincides with the outer periphery of the rear end surface 2 - 1 of the box body of the van or container freight truck 2 . Such an arrangement can effectively reduce the turbulent flow separation zone of the airflow at the tail of the box body of the van or container freight truck, and reduce the area of the negative pressure zone. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 Note that the wall thickness w of the quadrangular truss drag-reducing cover in this embodiment is 6 mm. Such setting can ensure the strength of the four-prism drag-reducing cover. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com