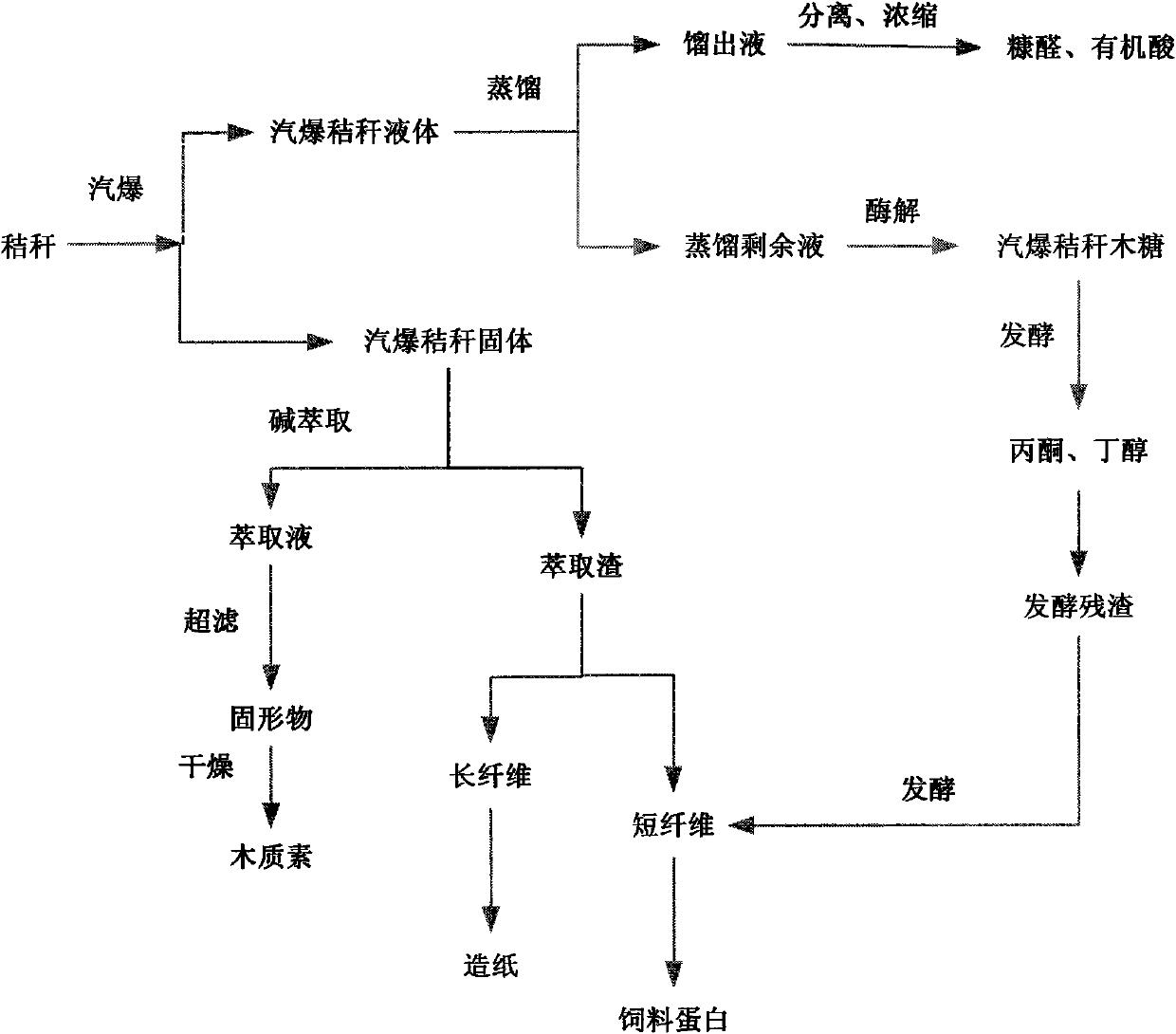

Method for producing acetone butanol by steam explosion straw xylose fermentation and extracting remainder

A technology for steam explosion of straw and acetone butanol, which is applied in the field of straw resource utilization, can solve the problems of affecting the normal growth of acetone butanol, acid pollution fermentation inhibitors, environmental pollution, etc., and achieves the effect of improving the comprehensive utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cut the corn stalks into 3-5cm sections, add 1 times of tap water and fully soak them for 10 minutes, put them into the steam explosion tank, pressurize them under the pressure of 1.5MPa for 5 minutes, and then release them rapidly from the reactor to obtain the steam explosion straws; add 2 double tap water, soak at 60°C for 20 minutes, and separate the steam-exploded straw liquid and steam-exploded straw solid with an extruder; after the steam-exploded straw liquid is filtered, it is distilled under reduced pressure at 0.9MPa and 60°C, and the distillate is separated and concentrated Obtain furfural and acetic acid; add xylanase to the residual liquid after distillation, and hydrolyze it at 50°C for 12 hours. The hydrolyzed liquid is successively treated with macroporous adsorption resin and basic anion exchange resin, and the xylose concentration of the obtained steam-exploded straw is 5%. , then adjust the pH to 6.5 with NaOH, add 3% nitrogen source, and 0.01% trace ...

Embodiment 2

[0033]Cut the corn stalks into 3-5cm sections, add 1 times of tap water and fully soak them for 10 minutes, put them into the steam explosion tank, pressurize them under the pressure of 1.5MPa for 5 minutes, and then release them rapidly from the reactor to obtain the steam explosion straws; add 3 double tap water, soak at 60°C for 20 minutes, and separate the steam-exploded straw liquid and steam-exploded straw solid with an extruder; after the steam-exploded straw liquid is filtered, it is distilled under reduced pressure at 0.9MPa and 60°C, and the distillate is separated and concentrated Obtain furfural and acetic acid; add xylanase to the remaining liquid after distillation, and hydrolyze it at 50°C for 12 hours. The hydrolyzed liquid is successively treated with macroporous adsorption resin and basic anion exchange resin, and the xylose concentration of the obtained steam-exploded straw is 4%. , then adjust the pH to 6.5 with NaOH, add 3% nitrogen source, and 0.01% trace ...

Embodiment 3

[0035] Cut the corn stalks into 3-5cm sections, add 1 times of tap water and fully soak them for 10 minutes, put them into the steam explosion tank, pressurize them under the pressure of 1.5MPa for 5 minutes, and release them from the reactor rapidly to obtain the steam explosion straws; add 4 double tap water, soak at 60°C for 20 minutes, and separate the steam-exploded straw liquid and steam-exploded straw solid with an extruder; after the steam-exploded straw liquid is filtered, it is distilled under reduced pressure at 0.9MPa and 60°C, and the distillate is separated and concentrated Obtain furfural and acetic acid; add xylanase to the residual liquid after distillation, and hydrolyze it at 50°C for 12 hours. The hydrolyzed liquid is successively treated with macroporous adsorption resin and basic anion exchange resin, and the xylose concentration of the obtained steam-exploded straw is 3%. , then adjust the pH to 6.5 with NaOH, add 3% nitrogen source, and 0.01% trace eleme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap