Self-propelled U-shaped trench earth ditching and lining integrated machine

A roadheader and self-propelled technology, which is applied in the field of self-propelled U-shaped trench earthmoving and lining integrated machine, can solve the problems of inability to complete anti-seepage lining, inability to form at one time, different depths of trenches, etc. High efficiency, the effect of standard section

Active Publication Date: 2011-01-12

湖北楚峰水电工程有限公司

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Self-propelled to solve the problems of different depths of ditches excavated by existing excavating machines, which cannot be formed at one time, and the lining layer of the existing lining machine is not dense, the surface is not smooth, and the anti-seepage lining at the corners of the ditch cannot be completed. U-shaped ditch earthwork excavation and lining integrated machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

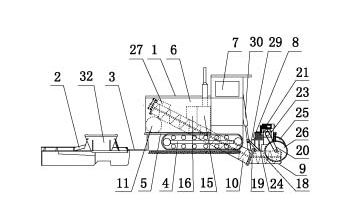

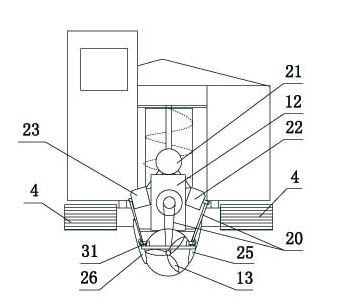

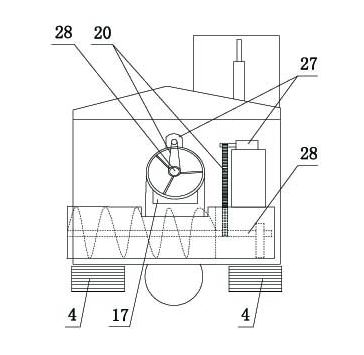

The invention discloses a self-propelled U-shaped trench earth ditching and lining integrated machine, which belongs to the technical field of trench excavating equipment. The machine consists of a ditcher and a lining device, wherein the ditcher consists of crawlers, a machine set chamber, a ditching barrel, a conveying barrel, a delivering barrel, a reducer, earth reaming blades and the like; and the lining device consists of a hopper, a guide slip form, a forming slip form, an edge pressing plate, a distributing plate and a wing plate. In the invention, a U-shaped trench is ditched on the ground by the earth reaming blades and an earth cutting disc at the front end of the ditcher, the excavated earth is delivered to one side of the trench by the delivering barrel, and the depth of the ditched trench can be regulated; and anti-seepage lining operation of the formed trench is completed by the lining device at the rear end, so that the ditching and the anti-seepage lining of the trench are completed by one machine. The integrated machine has the advantages that: the ditched trench has a smooth bottom surface and a standard section; working efficiency is high; the problems of inconsistent depth of the trench ditched by the conventional machinery and incompactness of a lining layer and the problem that lining operation cannot be carried out at the corner of the trench are solved; and the integrated machine is suitable for ditching work in the industrial and agricultural production.

Description

technical field [0001] The invention relates to a self-propelled U-shaped ditch earthwork excavation and lining integrated machine, which belongs to the technical field of ditch excavation equipment. Background technique [0002] In industrial and agricultural production, it is often necessary to excavate U-shaped ditches on the ground. The excavation of existing ground ditches generally relies on machinery or manual excavation. At present, there are mainly three types of excavation machinery. One is the plow-type ditching machine, which works like plowing the ground. The defect is that the traction resistance is large when ditching; the second is the rotary ditching machine, which works like Milling with milling cutters has the disadvantages of high power consumption and low efficiency; the third type is various types of excavators, whose working principle is backhoe digging and rotary unloading. The defect is that the channel cannot be U-shaped, and the excavated trench ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02F5/02E02F5/10

Inventor 孙春光刘昌元郭其华唐华山邓天平

Owner 湖北楚峰水电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com