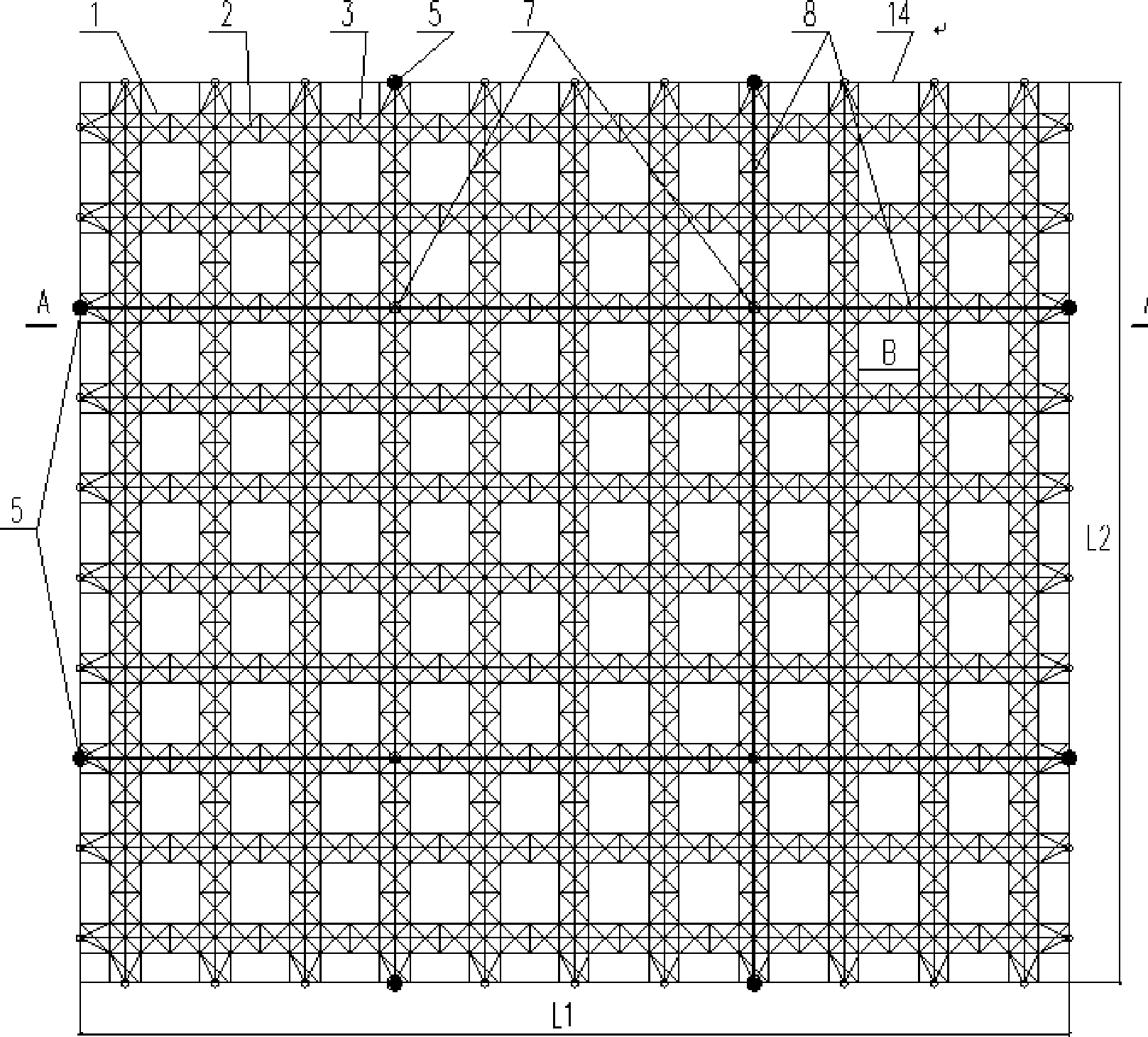

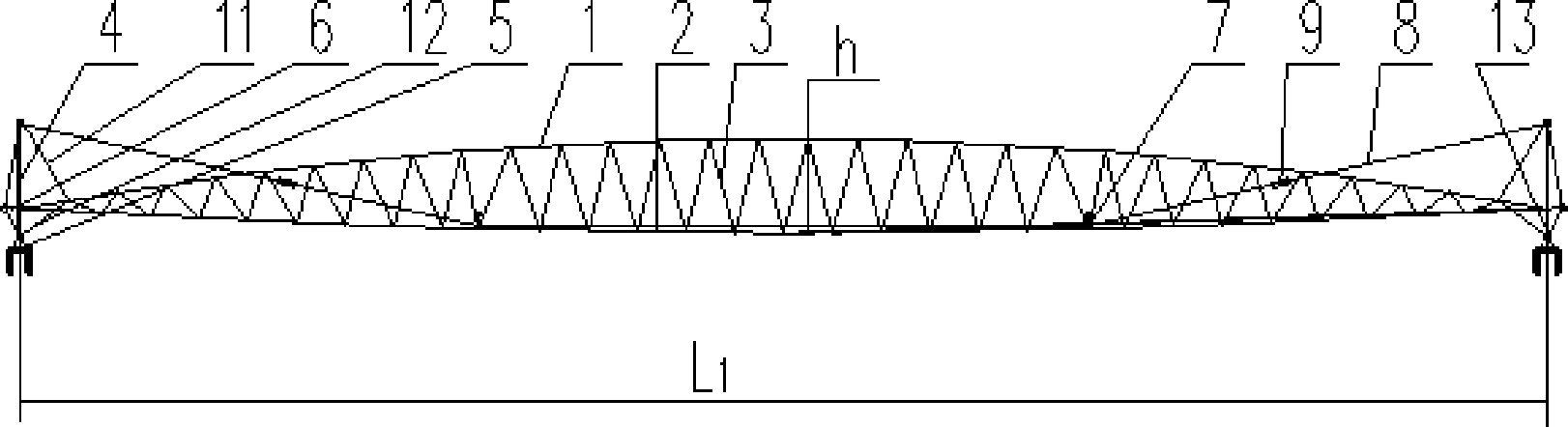

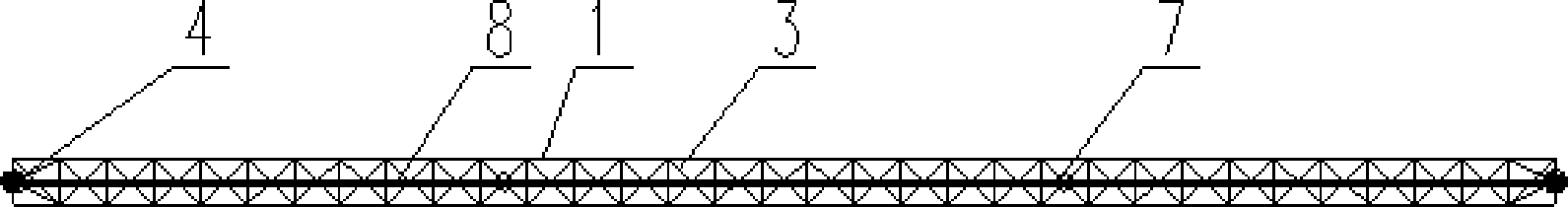

Roof with approximately quadrate plane and super large space pre-stressed steel grid structure and manufacturing method thereof

A grid structure, prestressed steel technology, applied in the direction of truss structure, girders, building structures, etc., can solve the problem of not meeting the needs of use, and achieve the reduction of steel consumption, structural height reduction, and internal force reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiment of the present invention: the ratio of the long side L1 and the short side L2 of the roof plane is 1≤L1 / L21 and 0.3L 2 The four shuttle-shaped space tube trusses at the position are made into support strut type cable-stayed self-balancing orthogonal space tube trusses, and at the same time, the four support bar-type cable-stayed self-balancing space tube trusses are connected orthogonally to each other; Control the central structure height of all the shuttle-shaped space tube trusses and the central structure height of the four-branched cable-stayed self-balancing orthogonal space tube trusses in the range of L2 / 18~L2 / 16, so that the A prestressed steel grid structure roof with an approximately square plane and super large space without columns in the middle is obtained; the support bar-type cable-stayed self-balancing orthogonal space tube truss is based on the structure of the conventional shuttle-shaped space tube truss, and Upper support rods for supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com