Micro-torque sensor calibrator based on magnetic suspension effect

A micro-torque and sensor technology, applied in the direction of force/torque/work measuring instrument calibration/testing, instruments, measuring devices, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

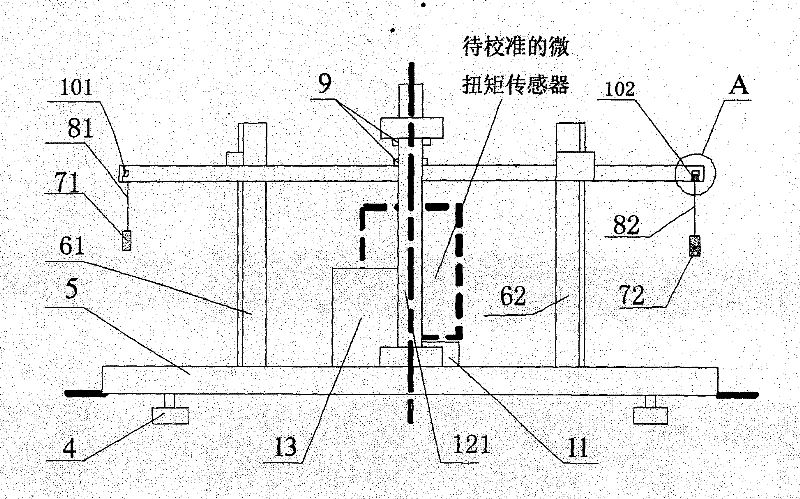

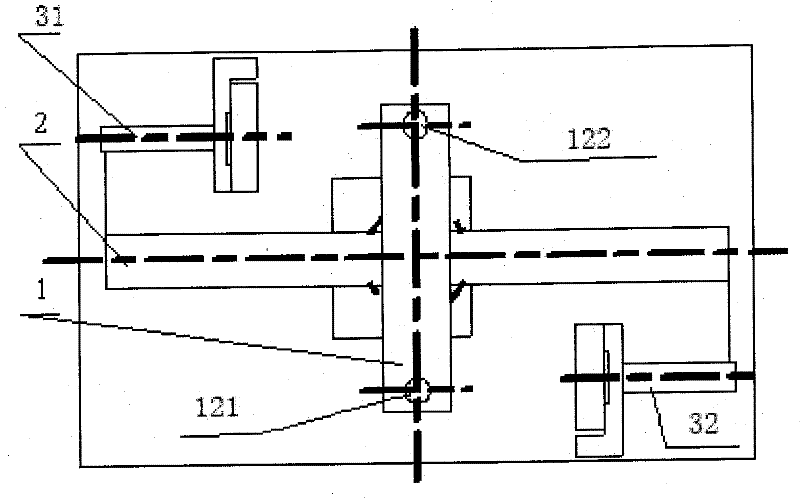

[0011] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a magnetic base 1, a moment arm 2, a first bearing frame 31, a second bearing frame 32, a height adjustment support foot 4, a base 5, a first guide rail 61, a second guide rail 62, and a first weight 71 , the second weight 72, the first lead wire 81, the second lead wire 82, the disk magnet, the first micro bearing 101, the second micro bearing 102, the tight block 11, the first guide post 121, the second guide post 122 , These elements of positioning block 13. The micro-torque sensor to be calibrated is placed vertically, fixed on the base 5 by the positioning block 13 and the tight block 11, the rotating shaft is equipped with the arm 2 of the arc edge; the first guide rail 61 and the second guide rail 62 are fixed on the base 5; The first bearing frame 31 is housed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com