Patents

Literature

32results about How to "Meet calibration requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-torque sensor calibrator based on magnetic suspension effect

InactiveCN101943625AMeet calibration requirementsSimple structureForce/torque/work measurement apparatus calibration/testingEngineeringBending moment

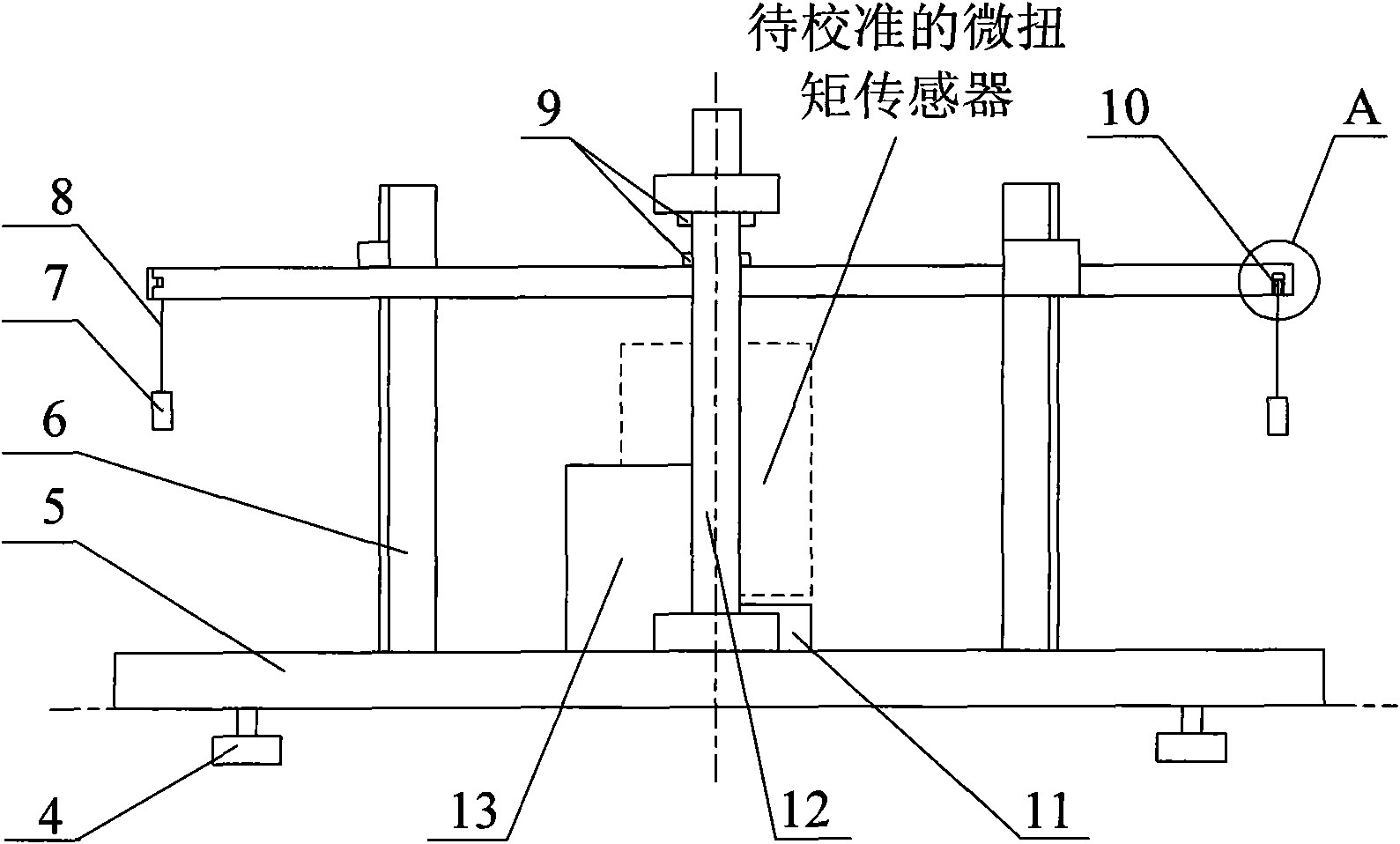

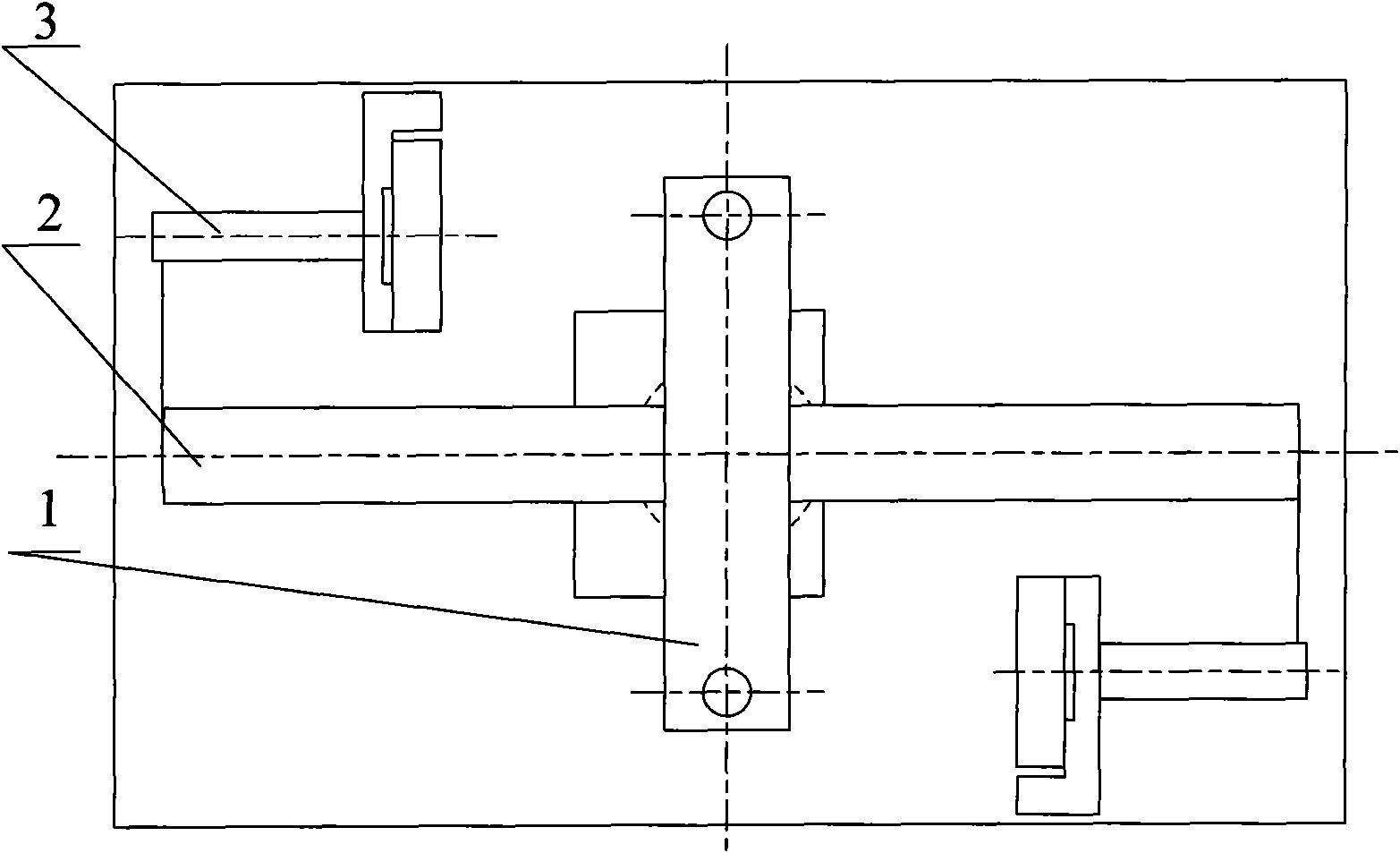

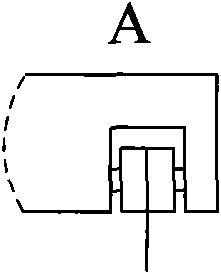

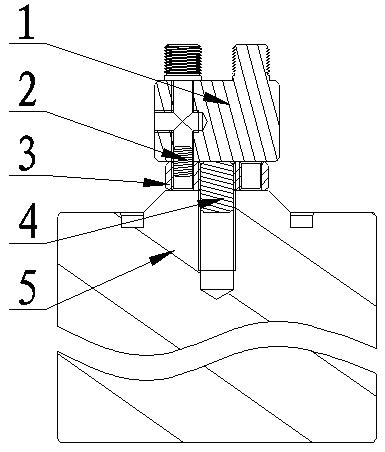

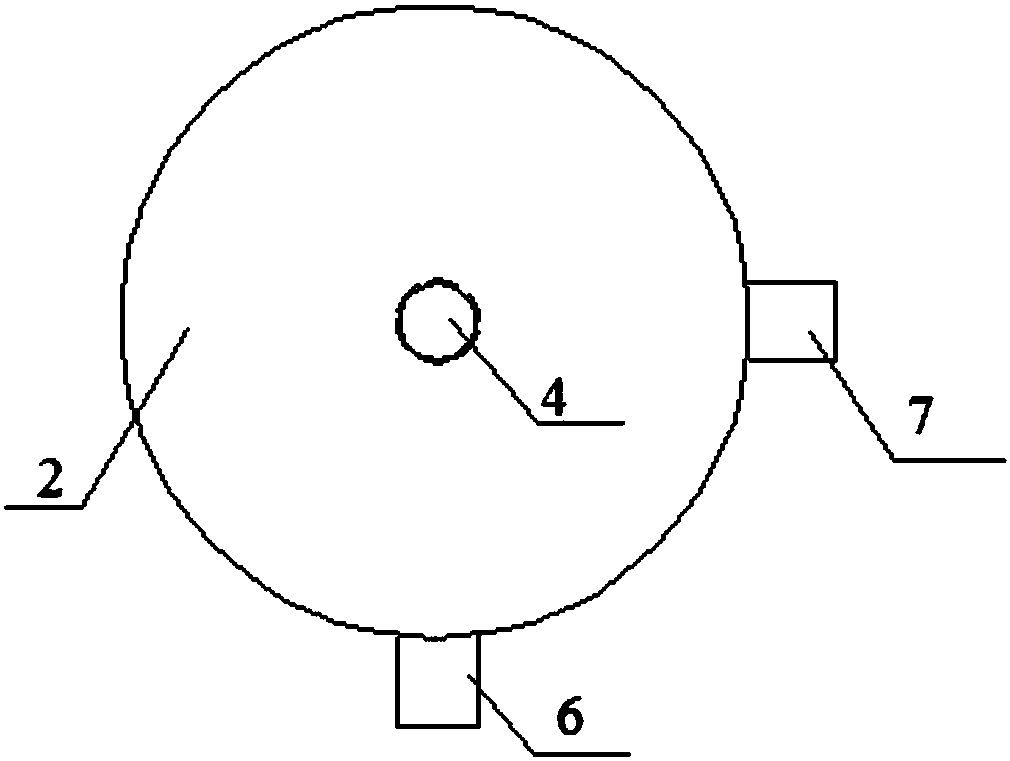

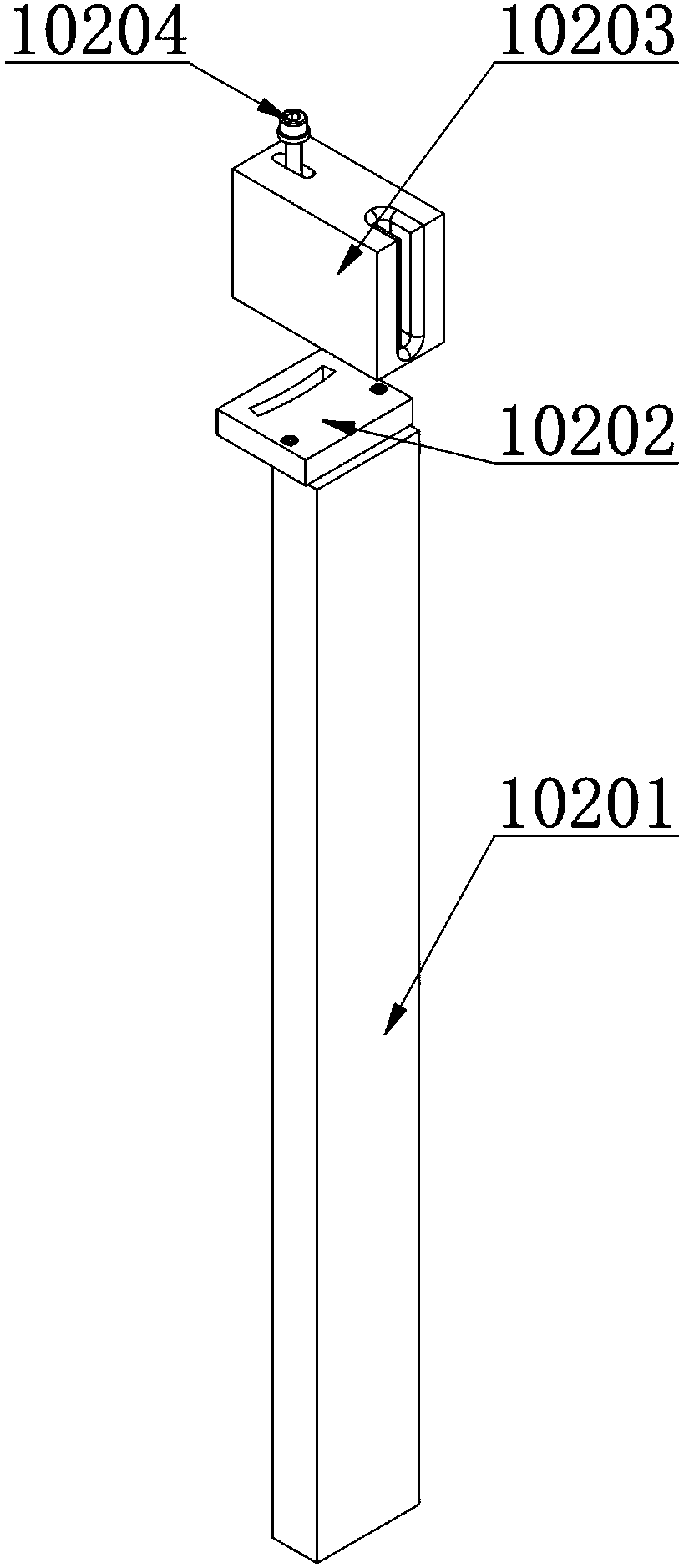

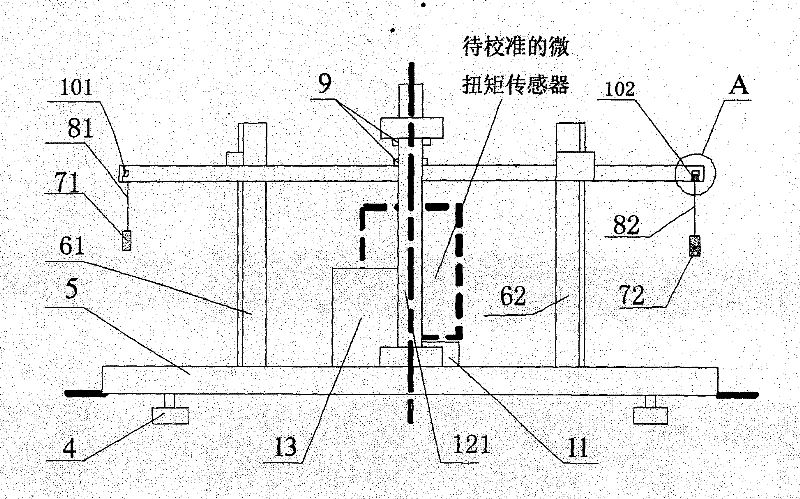

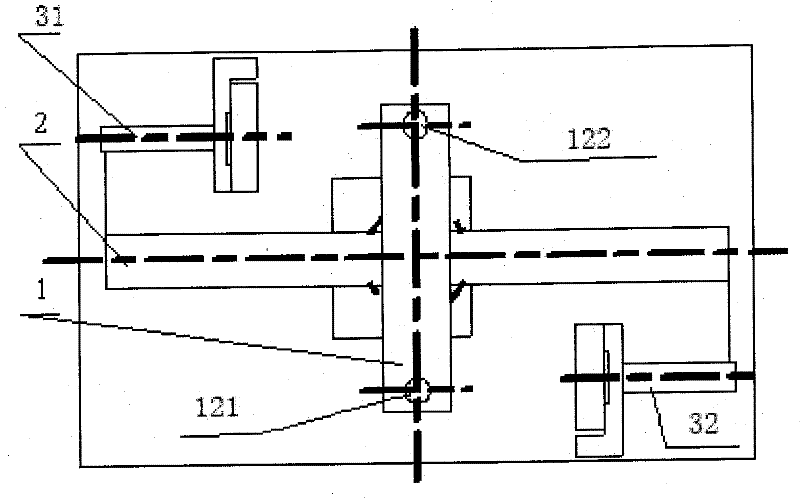

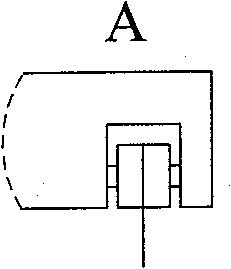

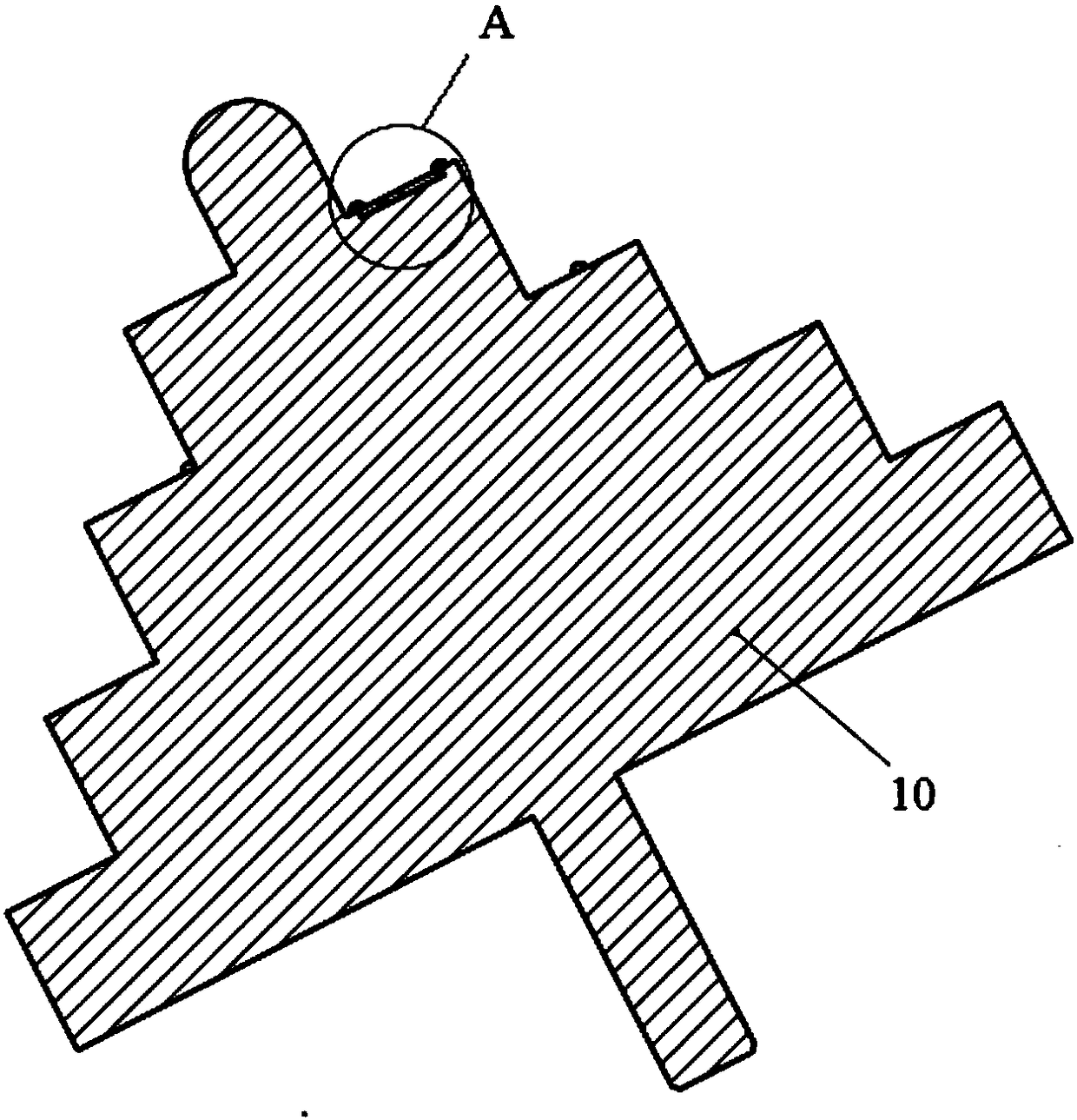

The invention discloses a micro-torque sensor calibrator based on a magnetic suspension effect. A microtorque sensor to be calibrated is fixed on a base by a positioning block and a clasping block; a moment arm with a circular arc side is installed on a rotating shaft; the bottom surface of the base is provided with a height adjusting support pin, and a guide column and a guide rail are installed on the height adjusting support pin; a bearing frame is installed on the guide rail, the edge of the bearing frame is slotted, and a micro-bearing is installed in a groove; a lead penetrates through the groove on the bearing frame and is hung on the micro-bearing, one end is fixed at the circular arc sides at both ends of the moment arm, and a weight is hung on the other end; a magnetic seat is installed on the guide column; and the central position of the moment arm and the central position of the magnetic seat are respectively provided with disk-shaped magnets. The invention can eliminate the bending moment applied to the rotating shaft of the microtorque sensor to be calibrated by moment arm weight during horizontal arrangement, realize pure torque loading, ensure that the torque is a constant value and meanwhile lead the moment arm to be in a suspension state, has the characteristics of simple structure, high precision and high stability and more favorably meets the calibrating requirement of the microtorque sensor.

Owner:台州市计量技术研究院

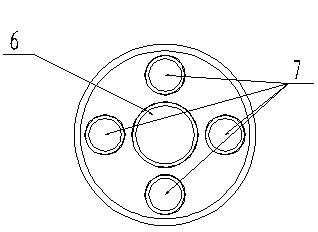

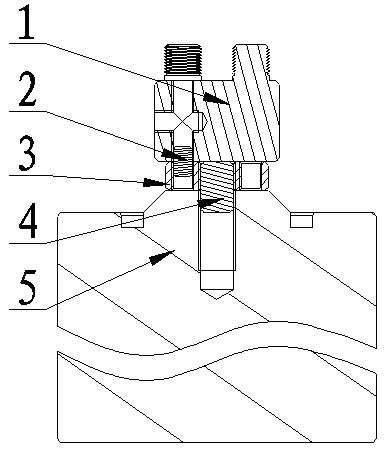

Calibration device of triaxial acceleration sensor and calibration method thereof

InactiveCN102411066AGuaranteed SensitivityHigh precisionTesting/calibration of speed/acceleration/shock measurement devicesVibration measurementVertical plane

The invention belongs to the engine vibration testing technology field, and provides a calibration device of a triaxial acceleration sensor. The device comprises a standard vibration source (5) and a switching pedestal (3). A central position of the switching pedestal (3) is provided with a screwed hole I (6). The switching pedestal (3) is fixed on the standard vibration source (5) with a stud I (4). Along periphery of the screwed hole I (6), an end face of the switching pedestal (3) is uniformly provided with a plurality of screwed holes II (7) used for connecting with the triaxial acceleration sensor (1). Three mutual vertical planes of the triaxial acceleration sensor are connected to the switching pedestal (3) through a stud II (2) in order. According to the device and the method in the invention, in the prior art, a problem that a standard vibration source can only calibrate sensitivity of one direction of the triaxial acceleration sensor to influence vibration measurement precision is solved, and sensitivity of the triaxial acceleration sensor in a vertical direction, an axial direction and a transverse direction are ensured.

Owner:HENAN DIESEL ENGINE IND

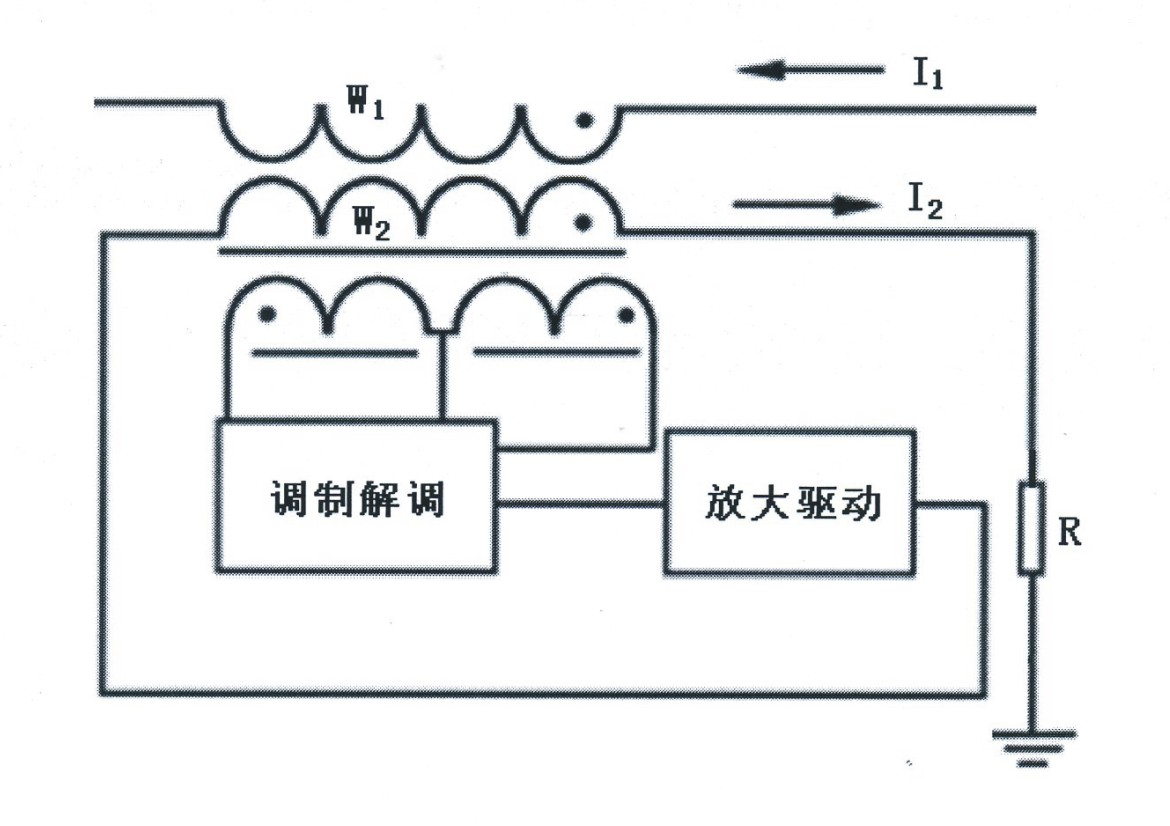

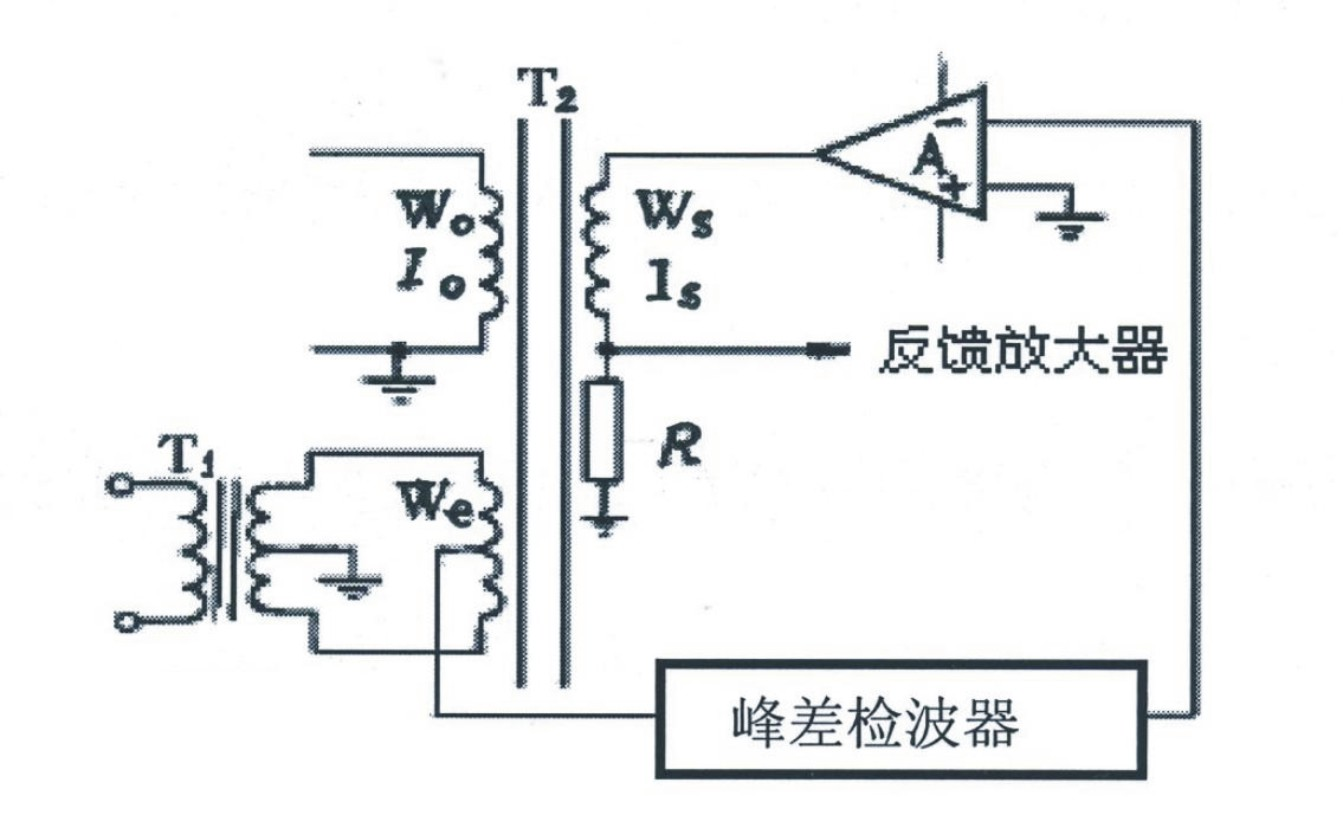

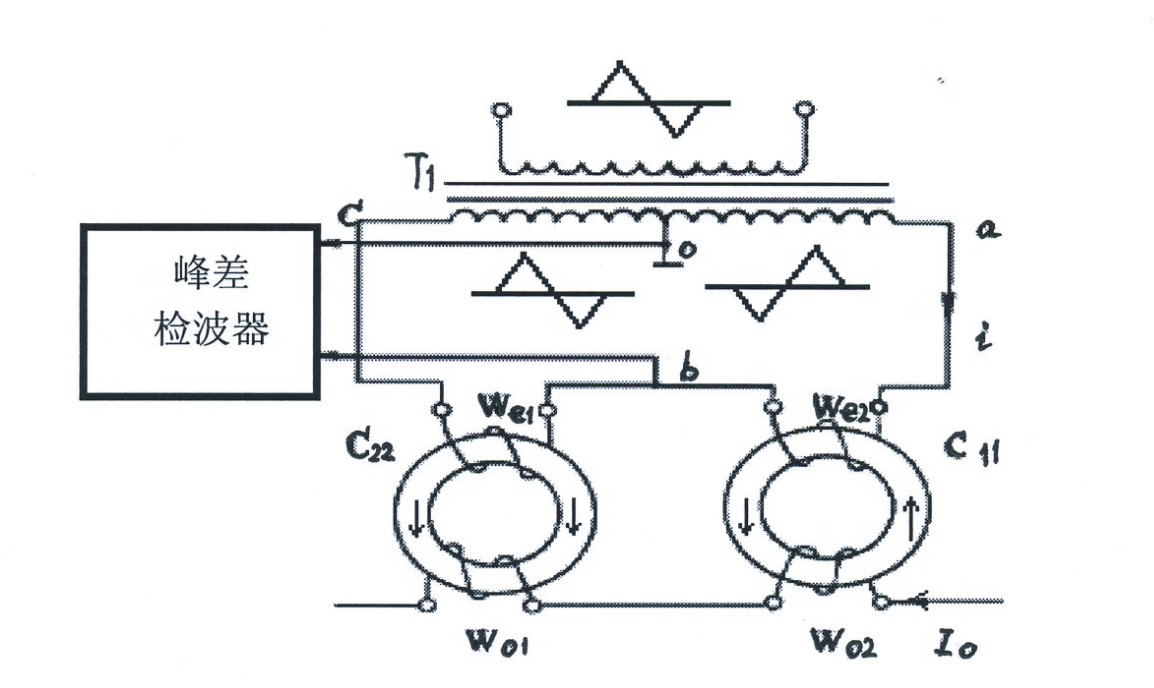

5-ka zero-track DC (direct current) comparator for calibrating current transformer

The invention relates to a 5-kA zero-track DC (Direct Current) comparator for calibrating a current transformer. A primary winding and a secondary winding are wound around a main iron core; an oscillator, a modulation circuit, a demodulation circuit and an amplification driving circuit are sequentially cascaded, the primary winding and the secondary winding are arranged outside a magnetic shield, and the primary winding penetrates out of an inner hole of the magnetic shield; the modulation circuit is formed by respectively winding two modulation detection windings with the same turns on an annular iron core in opposite winding directions; the magnetic shield is wrapped outside the two modulation detection windings, and the two modulation detection windings and the secondary coil of the oscillator are sequentially connected in series; and the demodulation circuit is a passive resistance-capacitance network circuit which is used for demodulating a difference-value signal from the modulation circuit into a DC voltage signal in direct proportion to the difference-value signal. The 5-kA zero-track DC comparator provided by the invention reaches the accuracy degree up to 2*10<-6> and fully meets the requirement for calibrating the DC transformer on site.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST

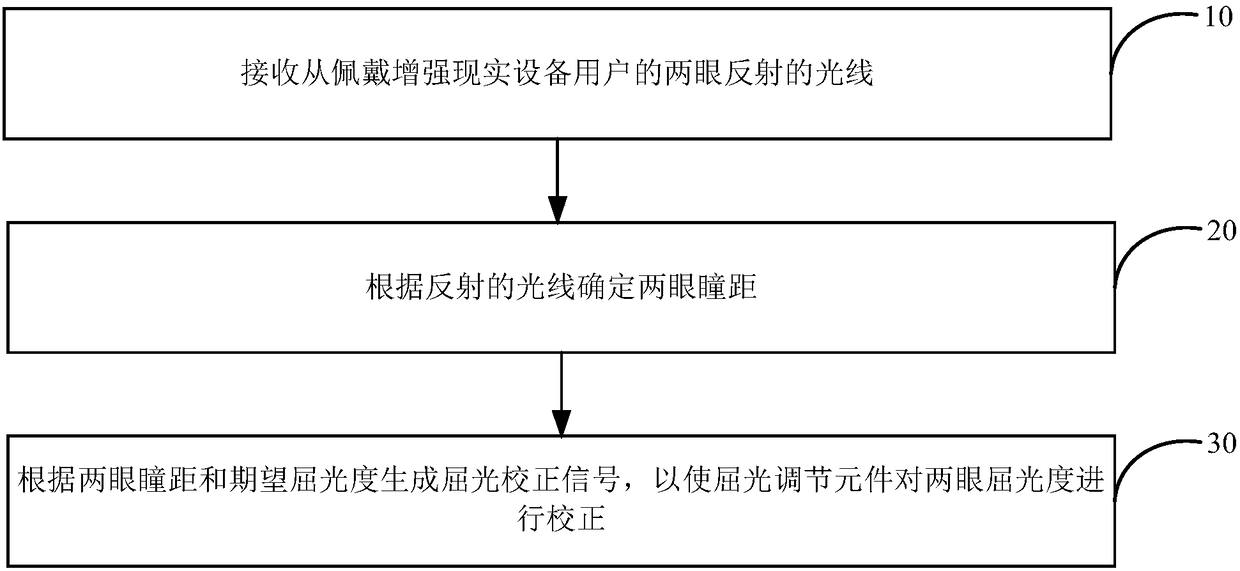

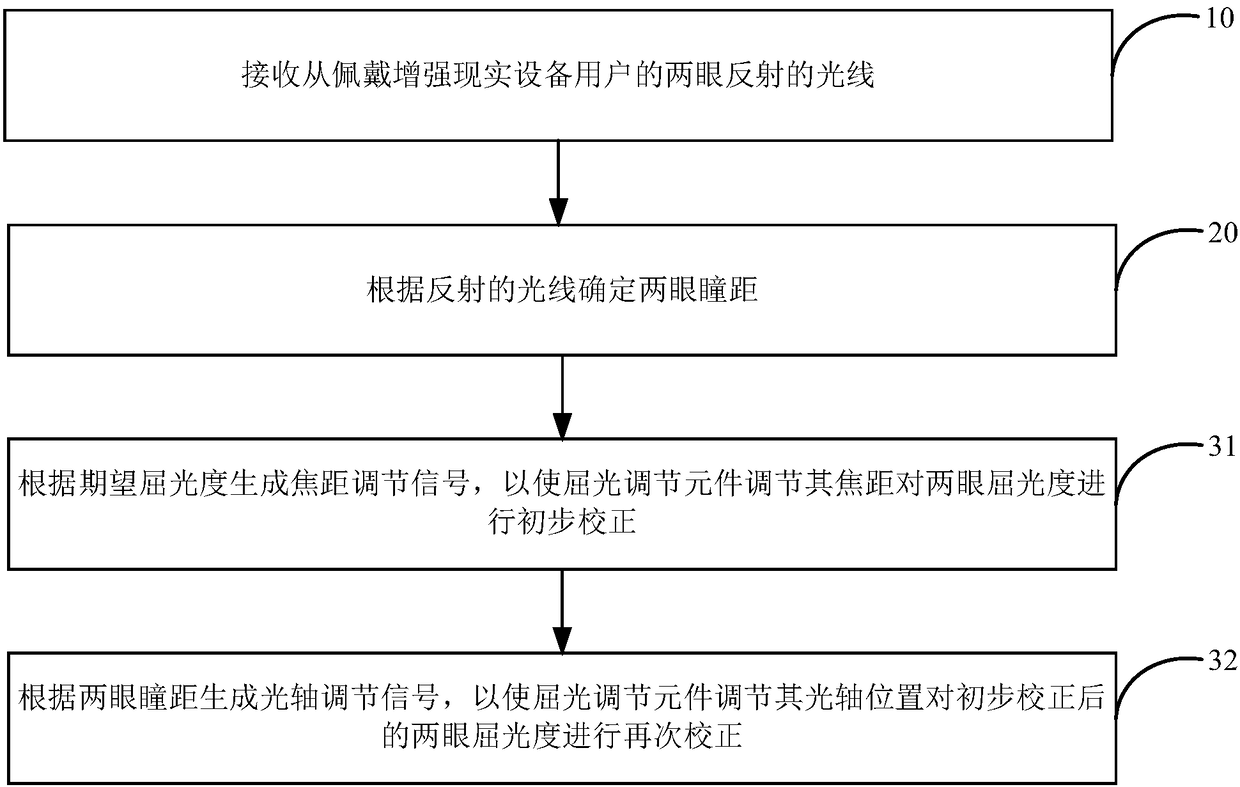

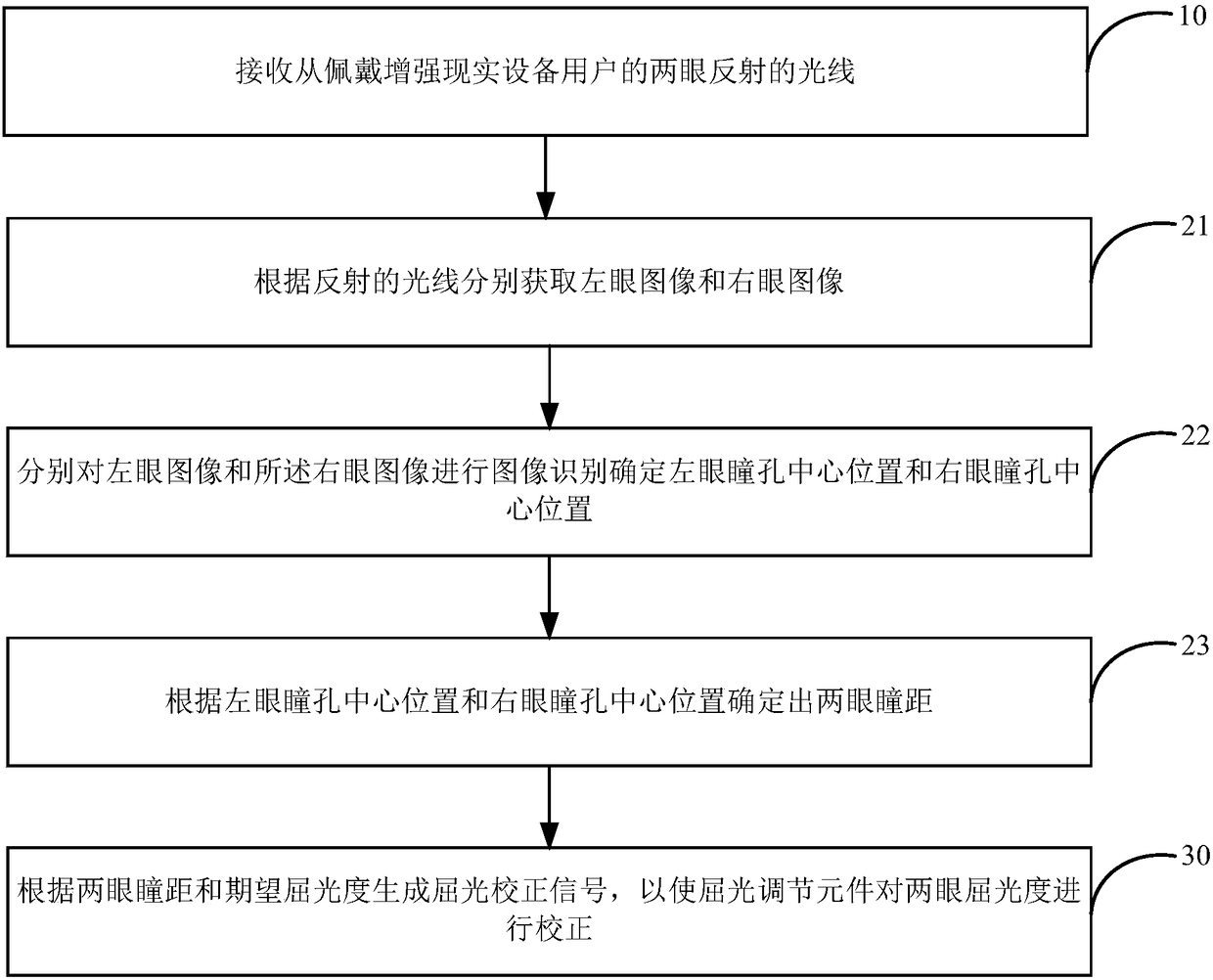

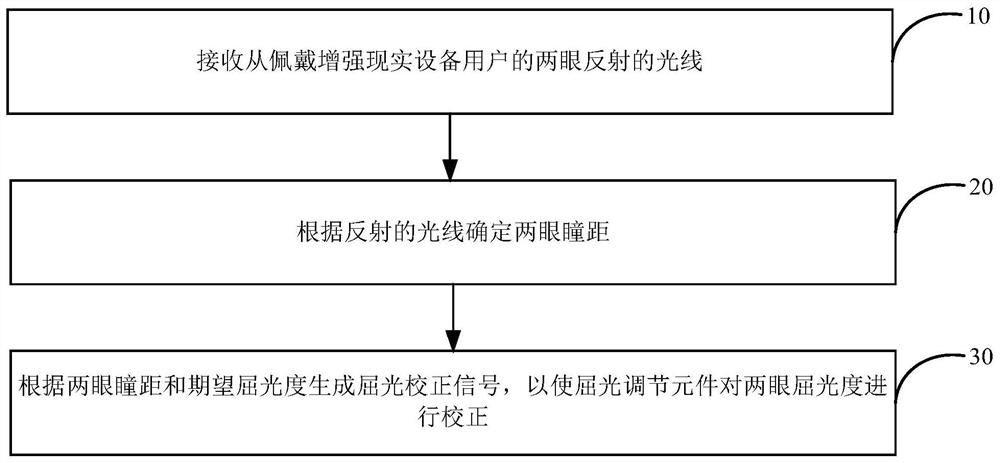

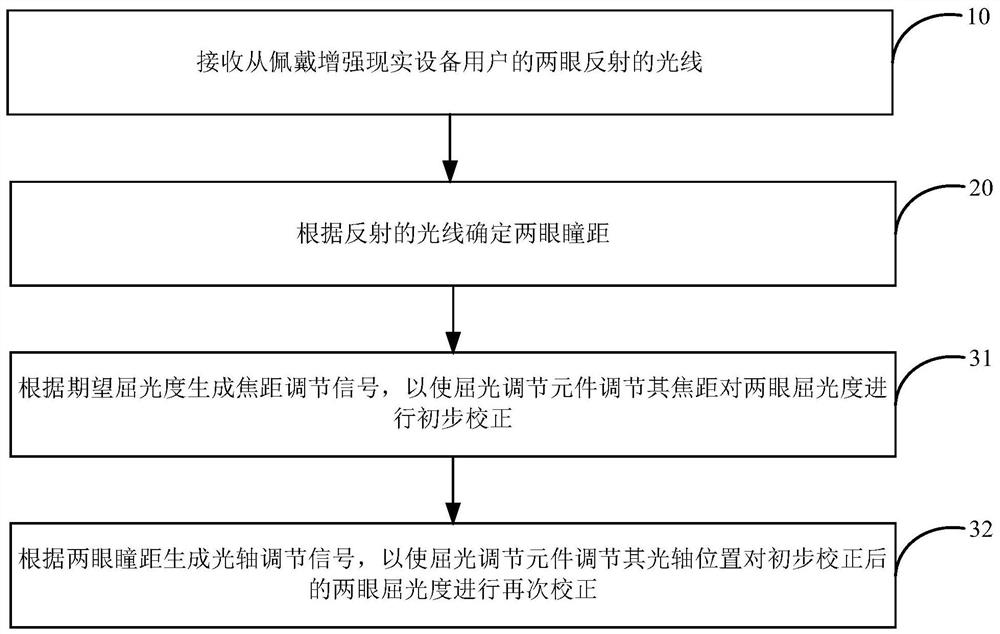

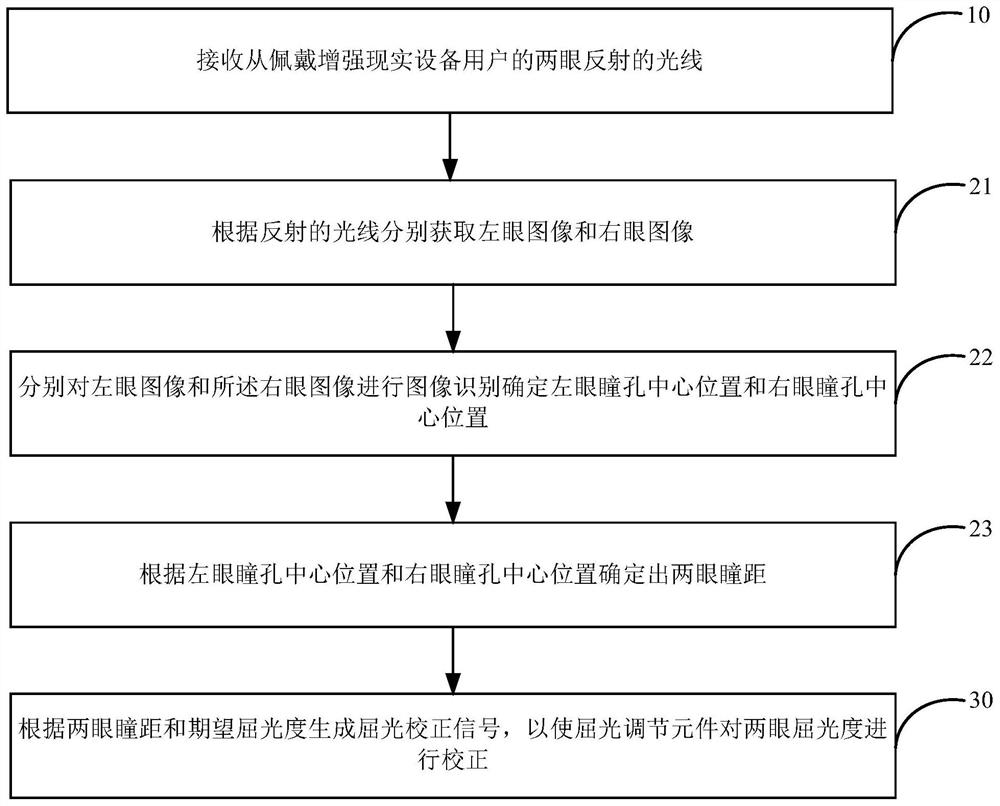

Refraction adjustment method and device for augmented reality device and augmented reality device

ActiveCN108490611AImprove comfortMeet calibration requirementsNon-linear opticsOptical elementsPupillary distancePupil

The invention discloses a refraction adjustment method and device for an augmented reality device and the augmented reality device. The method comprises a step of receiving light reflected from two eyes of a user wearing the augmented reality device, a step of determining a pupil distance between the two eyes according to the reflected light, and a step of generating a refraction correction signalaccording to the pupil distance between the two eyes and a desired refraction degree such that a refraction adjustment component corrects the refraction of the two eyes, and the comfort of using theaugmented reality device can be improved.

Owner:BOE TECH GRP CO LTD

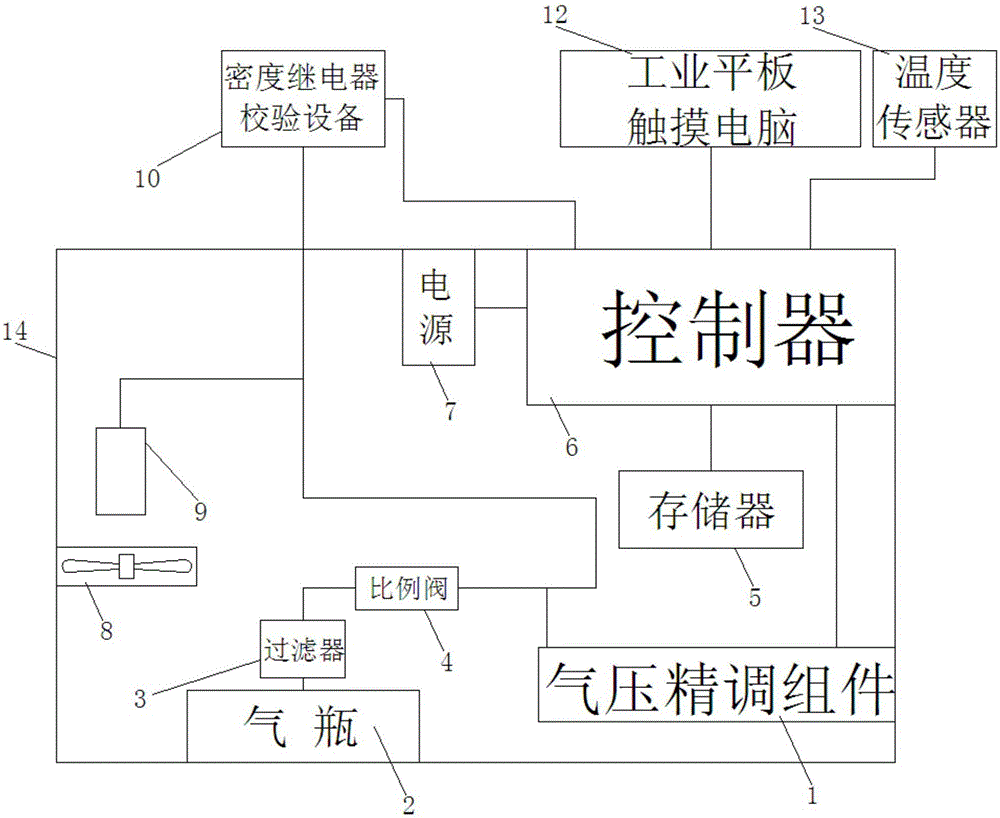

Calibrating device for SF6 density relay checking instrument

InactiveCN105116363AGuaranteed safe operationEasy maintenanceElectrical measurementsGas cylinderSLATES

The invention discloses a calibrating device for an SF6 density relay checking instrument. The calibrating device comprises a controller, wherein the controller is connected with an industrial slate computer, a temperature sensor and to-be-checked density relay checking equipment, wherein the controller is connected with a signal line interface of the to-be-checked density relay checking equipment; the calibrating device further comprises a gas filling tube communicated with a gas filling port of the to-be-checked density relay checking equipment; a gas cylinder and a proportional valve are connected in series onto the gas filling tube sequentially; a gas pressure fine-adjustment assembly and a pressure sensor are further arranged on the gas filling tube; the gas pressure fine-adjustment assembly, the gas cylinder, the proportional valve and the pressure sensor are connected to the controller through a circuit; the controller is further connected with a storage device and a power supply; the pressure measurement range of the pressure sensor is 0-0.9 MPa; the resolution of the pressure sensor is smaller than or equal to 0.00002 MPa.

Owner:XIAN YA NENG ELECTRIC CO LTD

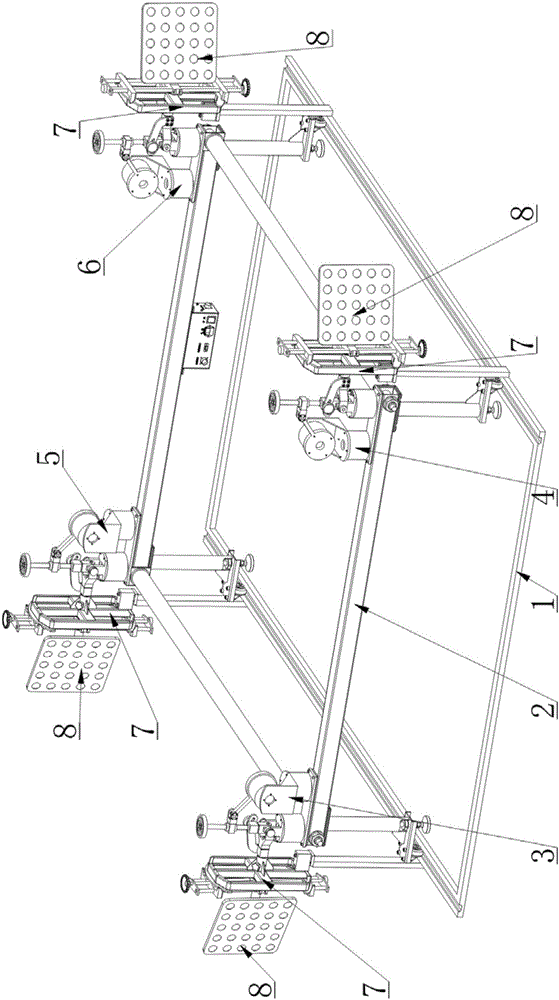

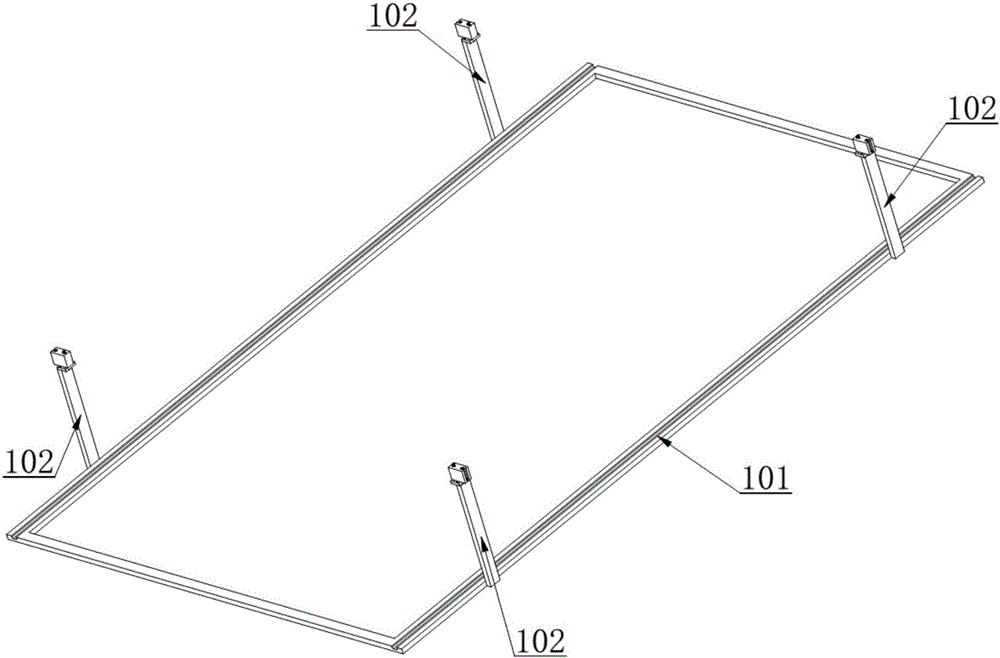

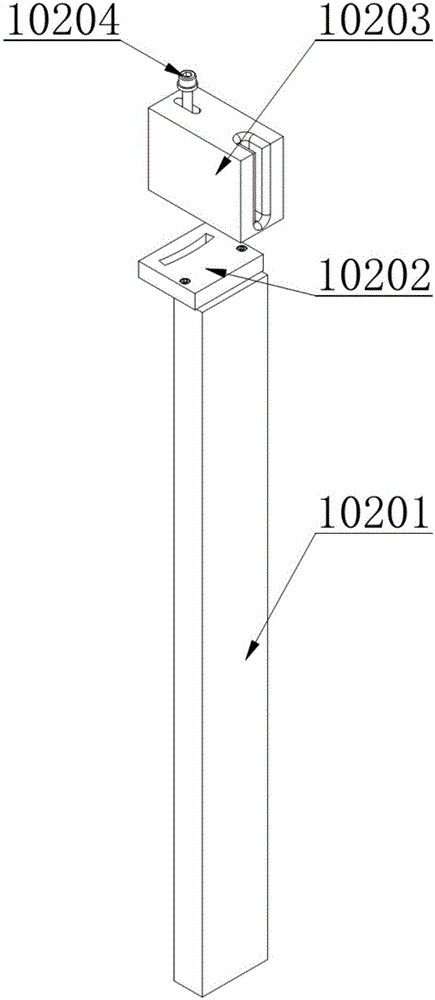

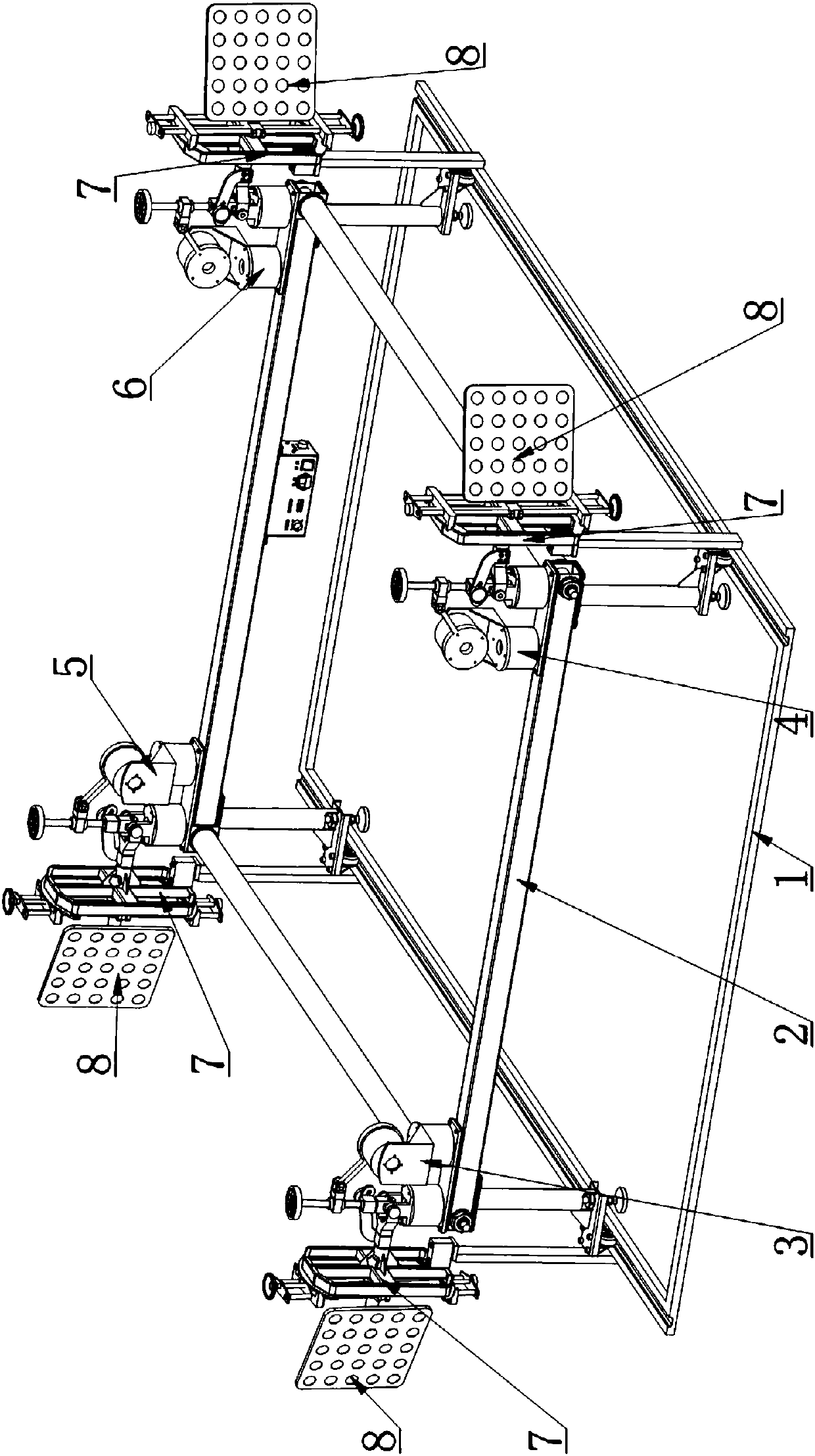

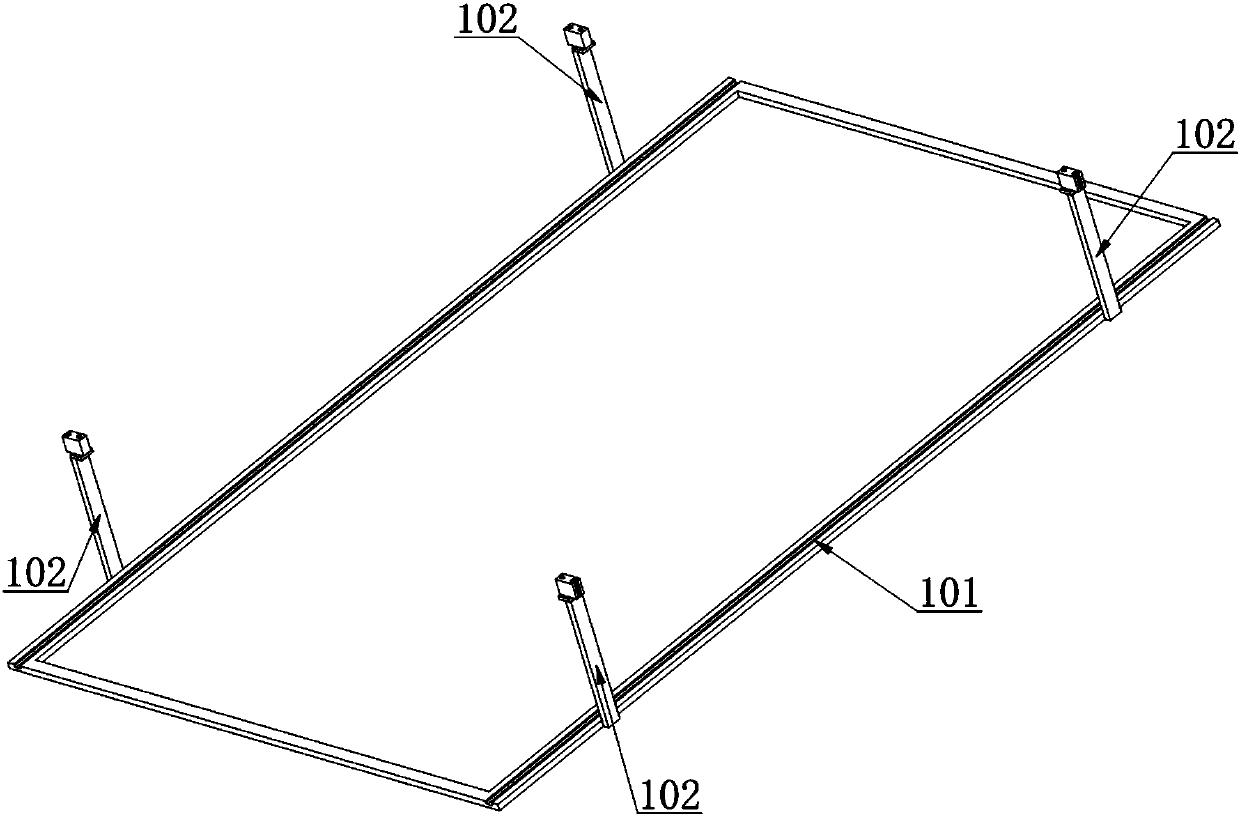

Synchronous position randomly adjustable image type calibrating device for four-wheel aligner

InactiveCN105699100AGuaranteed to drive in a straight lineMeet calibration requirementsVehicle wheel testingEngineeringLarge size

The invention relates to a synchronous position randomly adjustable image type calibrating device for a four-wheel aligner, and belongs to the calibrating devices for an automobile detection device. The synchronous position randomly adjustable image type calibrating device comprises a synchronous mechanism dragging rack, a front beam zero-point test jig, a front left bench examination portion, a front right bench examination portion, a rear left bench examination portion, a rear right bench examination portion, simulating wheel hubs and four wheel clamp assemblies. The synchronous position randomly adjustable image type calibrating device overcomes the defects of large size, heavy dead weight, high assembly difficulty and low accuracy of a conventional calibrating device due to a complex structure, and ensures more accurately measuring wheel positioning parameters.

Owner:JILIN UNIV

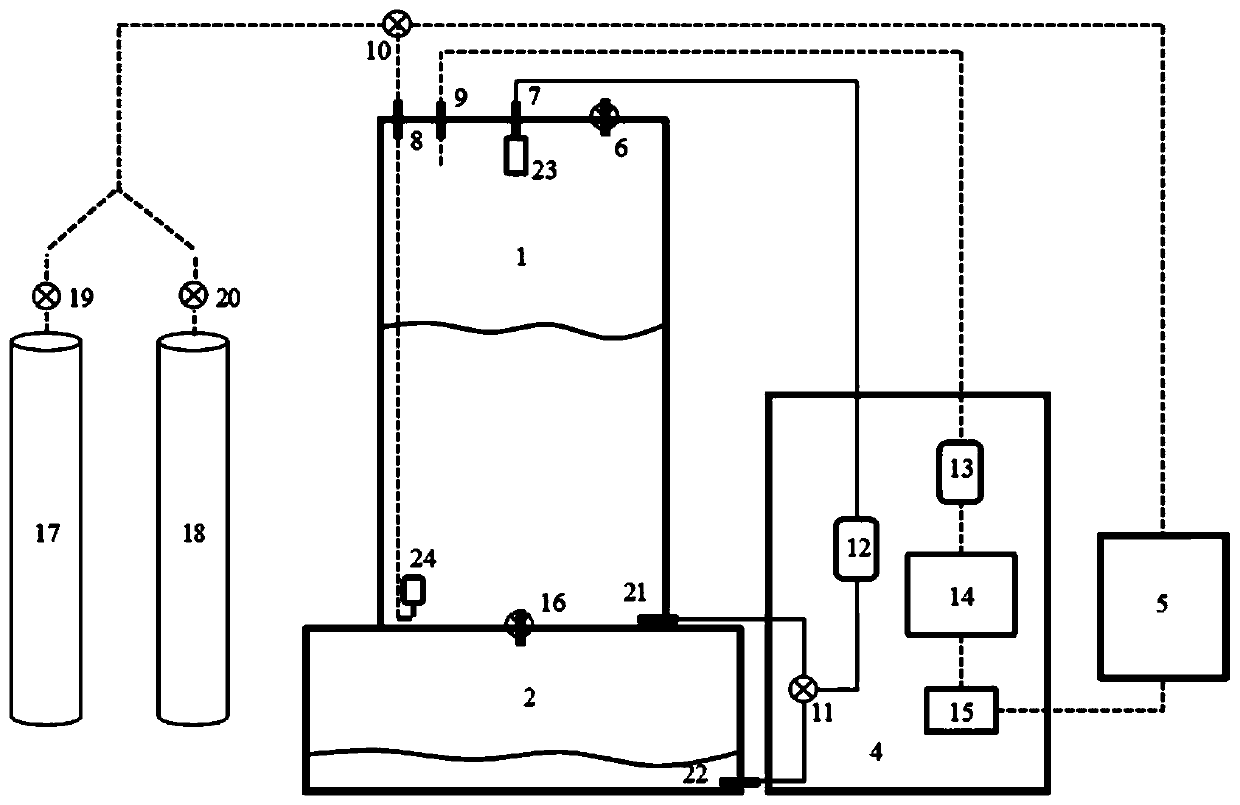

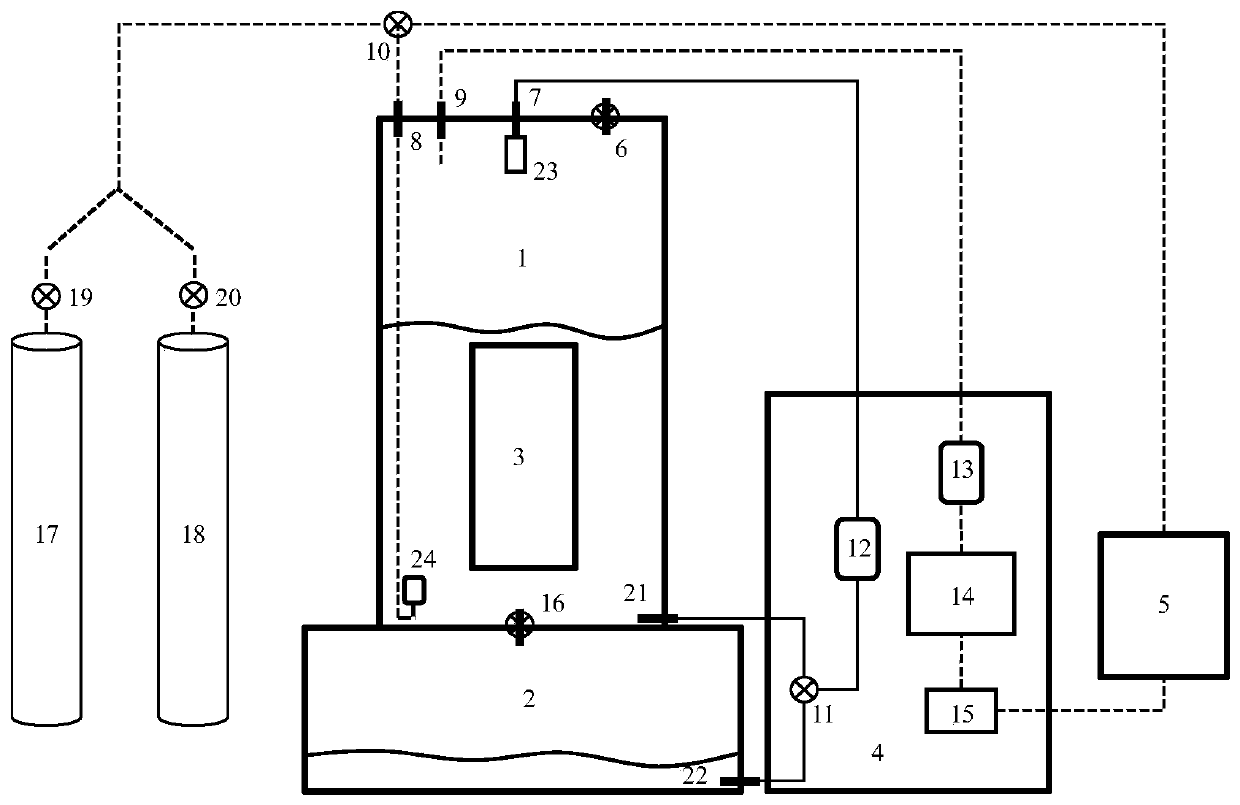

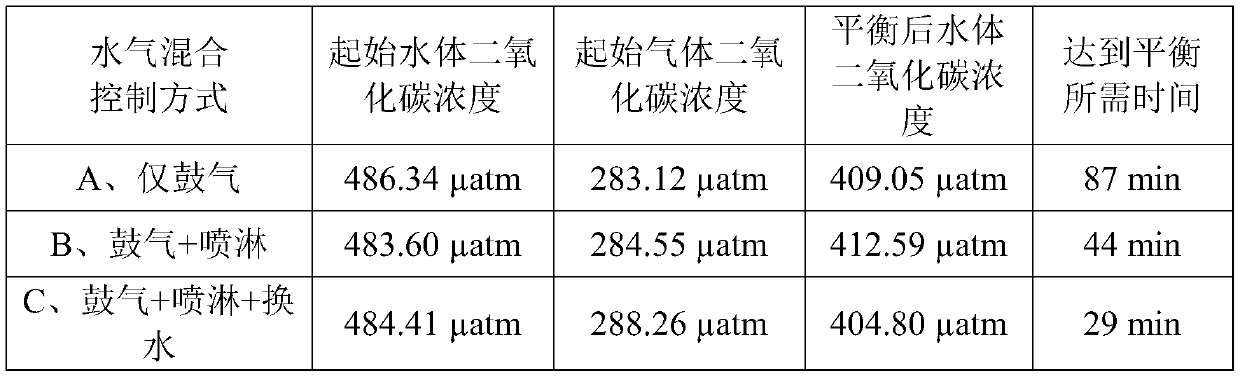

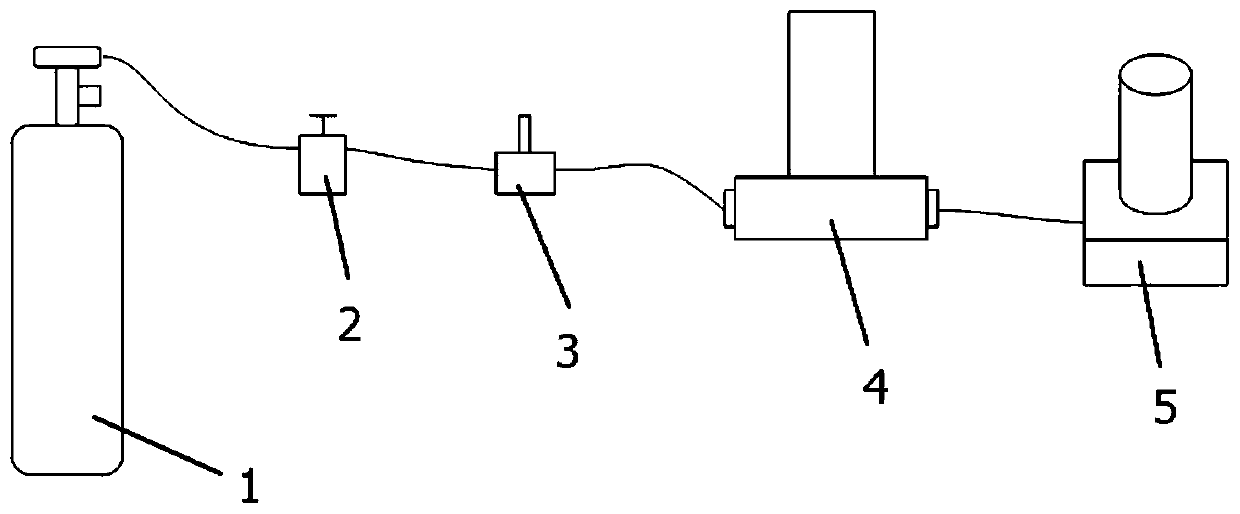

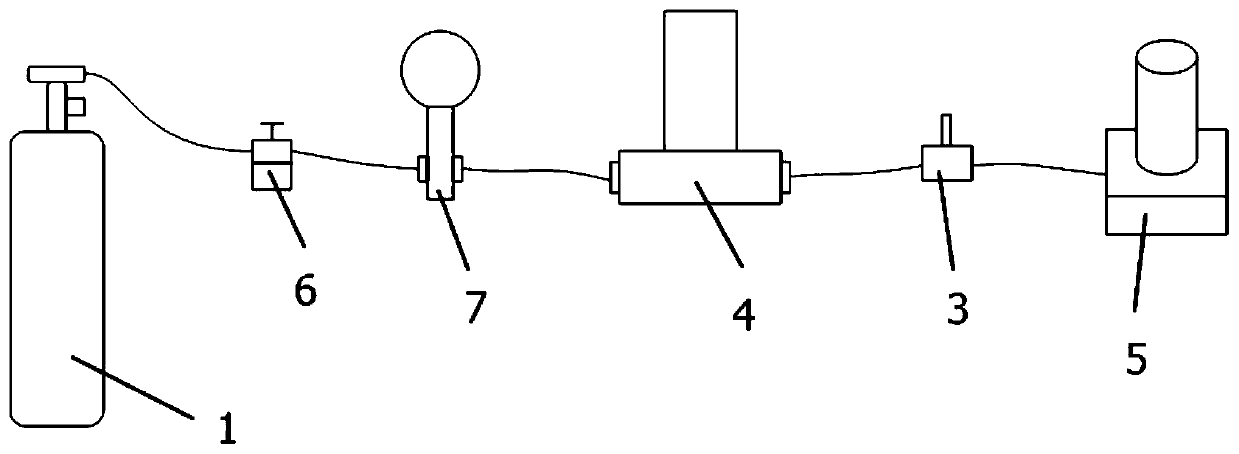

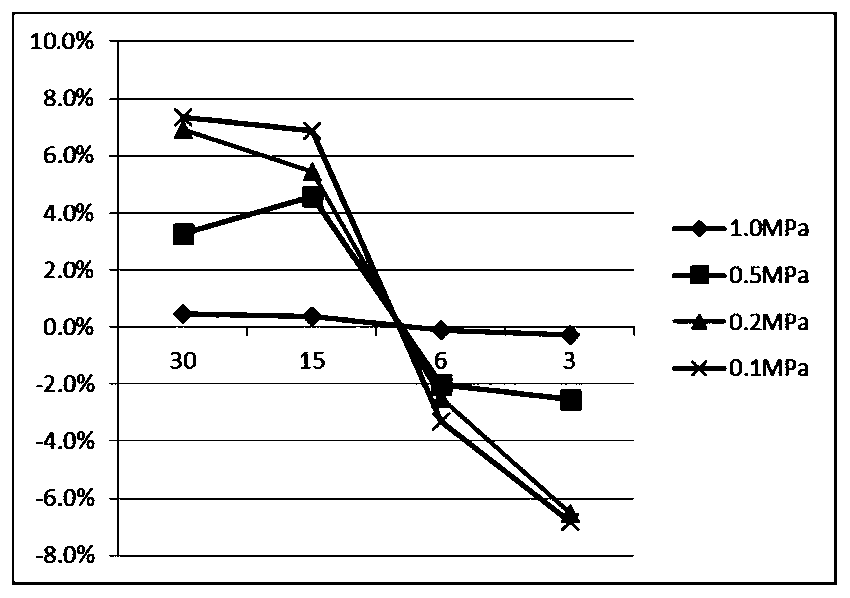

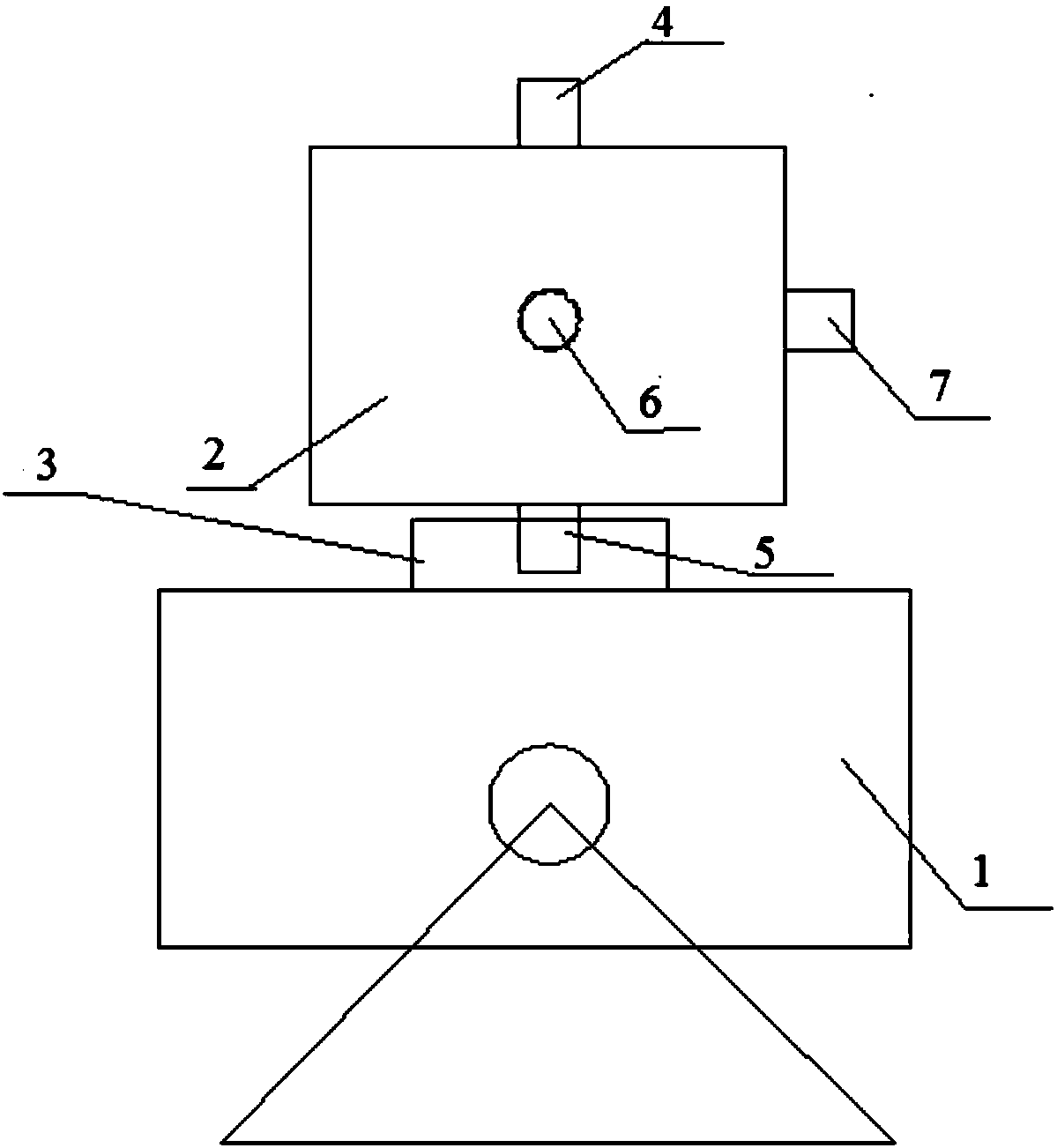

High-precision and high-efficiency calibration device and method for seawater carbon dioxide sensor

PendingCN110873787AIncrease volumeMeet calibration requirementsPreparing sample for investigationTesting waterWater storageEnvironmental engineering

The invention discloses a high-precision and high-efficiency calibration device and method for a seawater carbon dioxide sensor. The calibration device comprises a gas supply device, a calibrator, a water storage device, a control box and a table type carbon dioxide gas analyzer. By adopting the design of the water storage device, a spray header and the like, the water-gas mixing efficiency is high, and the overall efficiency of the calibration test can be ensured. Bin opening is not needed in the whole testing process of the device, all operations such as water discharging, water feeding, airblowing, circulating and detecting can be achieved through switching of valves such as an air control three-way valve, a water control three-way valve and a water control valve, and interference of an external environment can be reduced to the maximum extent. The reference value of the calibration test is the measured value of the concentration of carbon dioxide in air in the calibrator after water-gas mixing balance, the measurement principle of the reference value is consistent with that of an internationally recognized underway carbon dioxide continuous observation system, and the accuracyof the reference value can be ensured.

Owner:SECOND INST OF OCEANOGRAPHY MNR

Calibration device and method for gas mass flow meter in special working state

The invention belongs to the technical field of flowmeter calibration, and discloses a calibration device for a gas mass flow meter in a special working state. The calibration device comprises a gas generator; the gas generator is communicated with a pressure reducing valve, a detected flow meter and a standard device in series or communicated with the detected flow meter and the standard device in parallel, and calibration of the detected flow meter under the conditions of pressure required by work, different component gases or polluted gases is completed. The invention further discloses a calibration method for the gas mass flow meter in the special working state.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

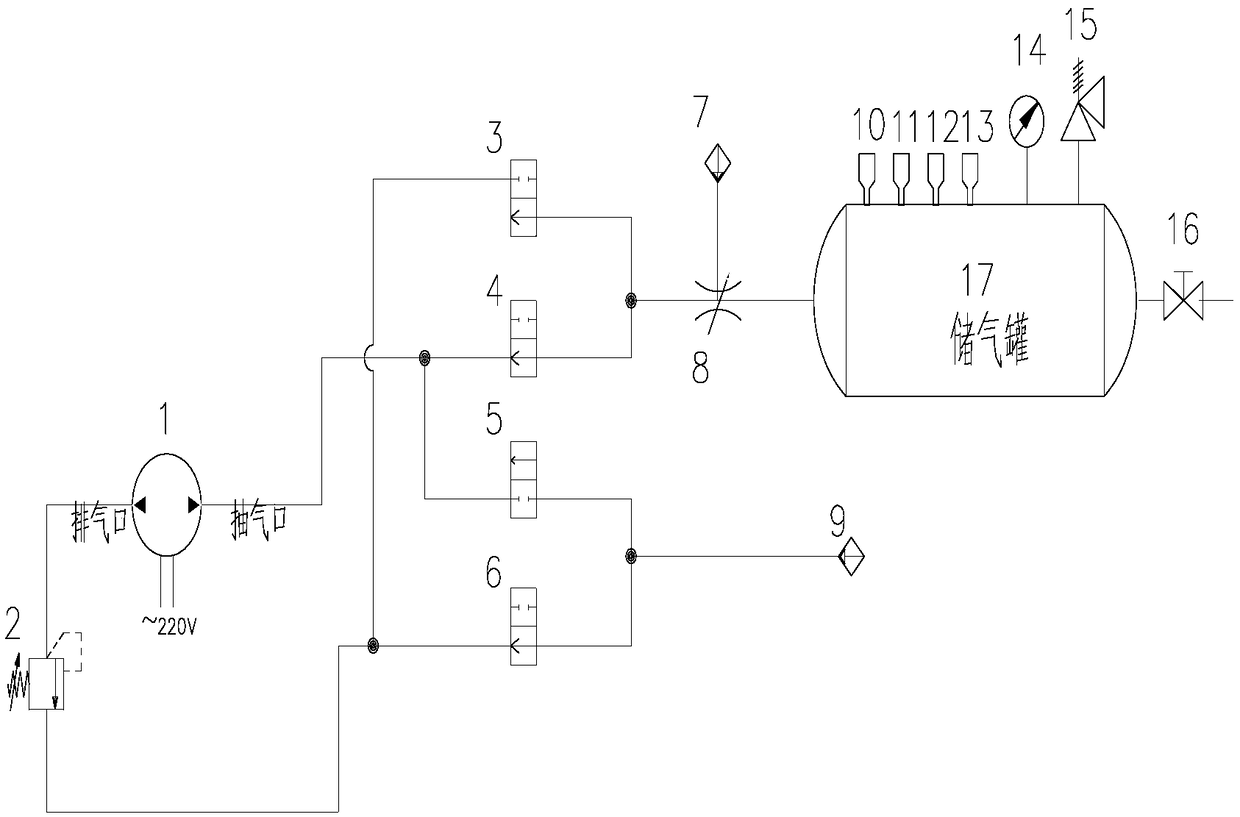

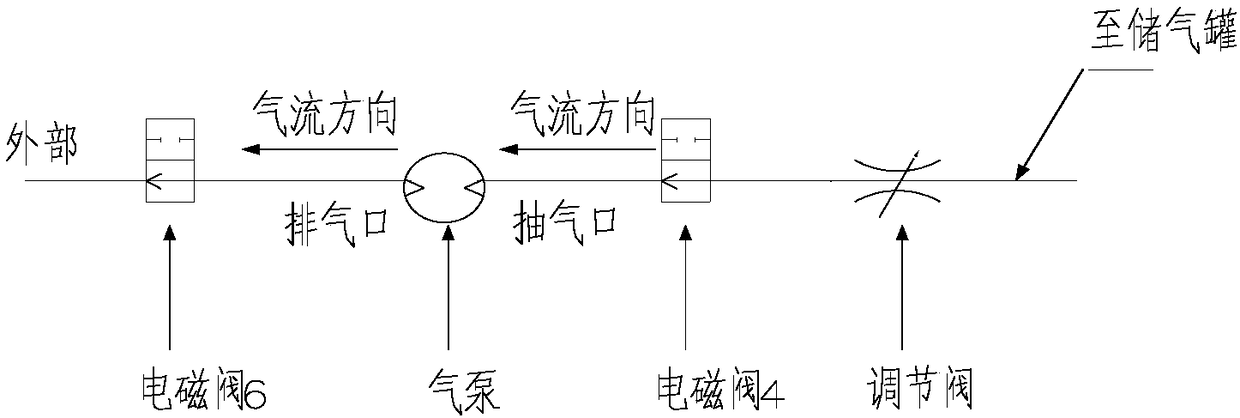

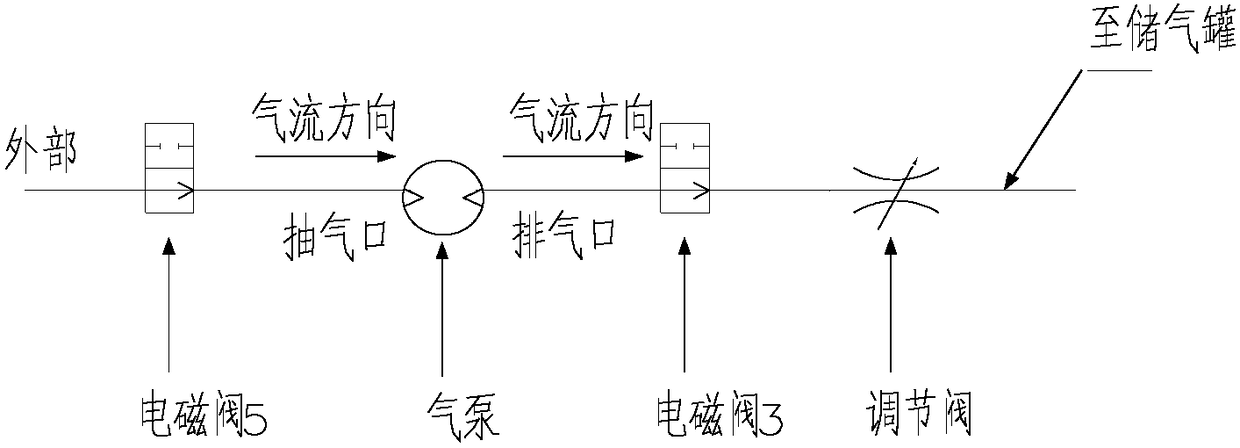

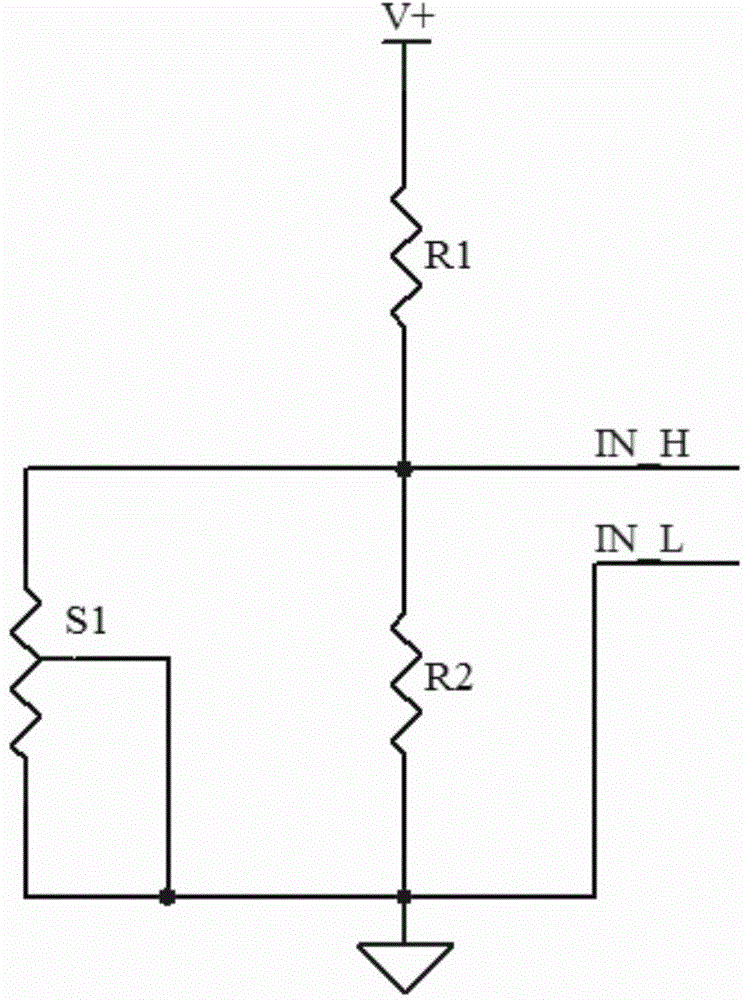

Portable negative pressure sensor field calibration device

InactiveCN108195508AMeet calibration requirementsSame conditionsFluid pressure measurementVacuum pumpingSolenoid valve

The invention provides a portable negative pressure sensor field calibration device. A miniature pump-and-pull dual-purpose air pump is used to connect a miniature air storage tank. Through controlling the switches of four two-position two-pass solenoid valves, automatic switching of an air exhaust or pumping air channel is realized. Two kinds of work modes, which are vacuum pumping and pressurization, are established. The precision regulating valve of a tee-junction structure is used to cooperate with a high-precision digital display pressure meter so that the pressure in the air storage tankcan be accurately controlled and a 10-300KPa continuous-adjustable pressure environment is formed. All components are installed in a calibration box which has a small size and is convenient to carry.The design of the device is reasonable, operation is simple and carrying is convenient. The device is suitable for negative pressure sensor calibration in a test and industrial field environment.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

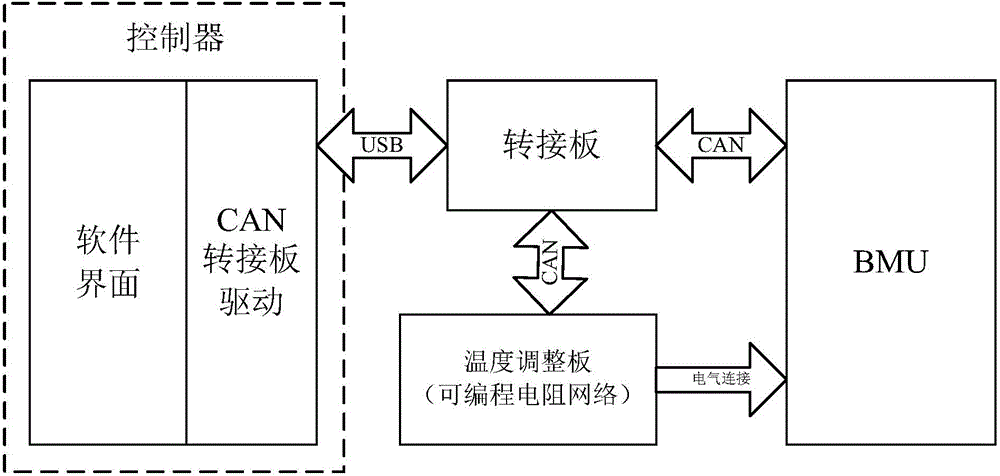

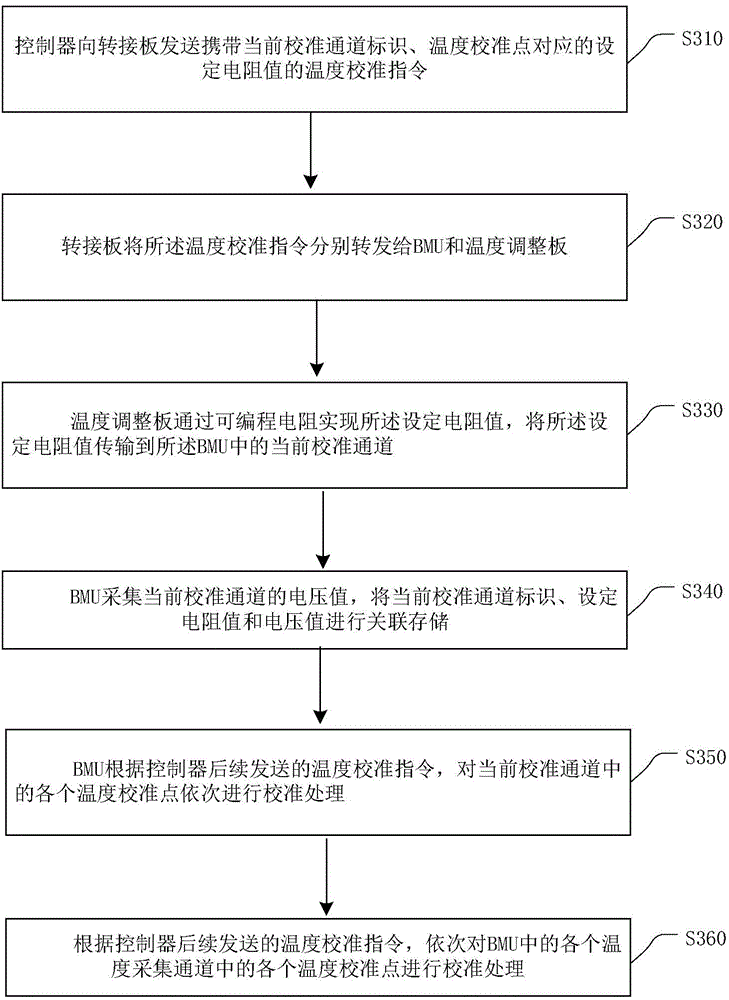

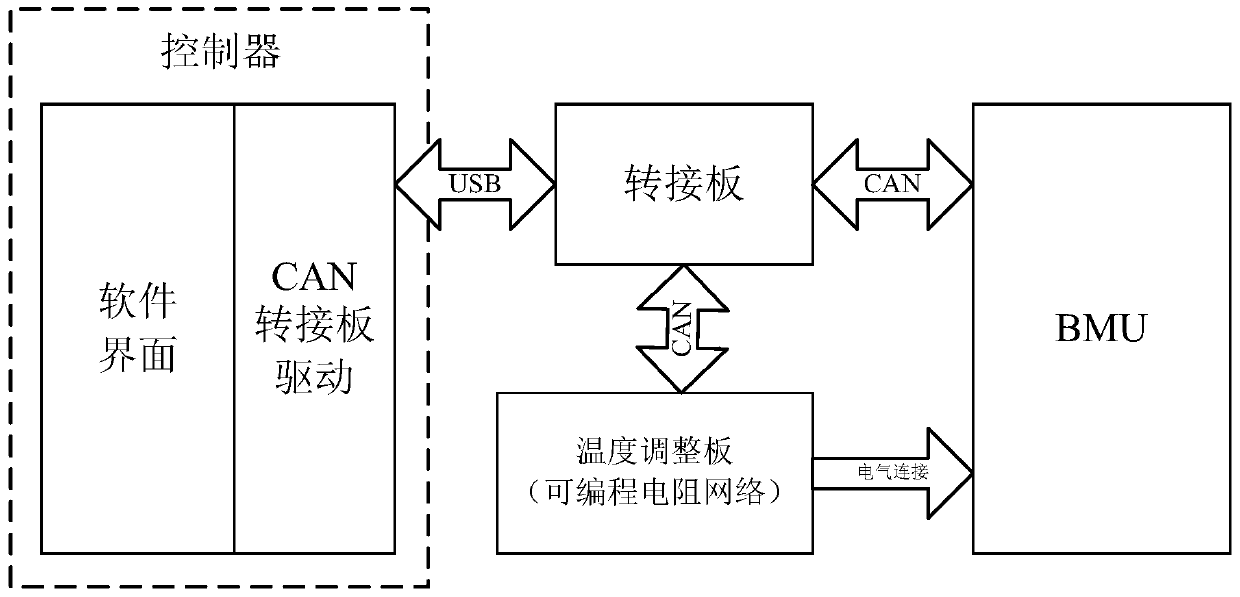

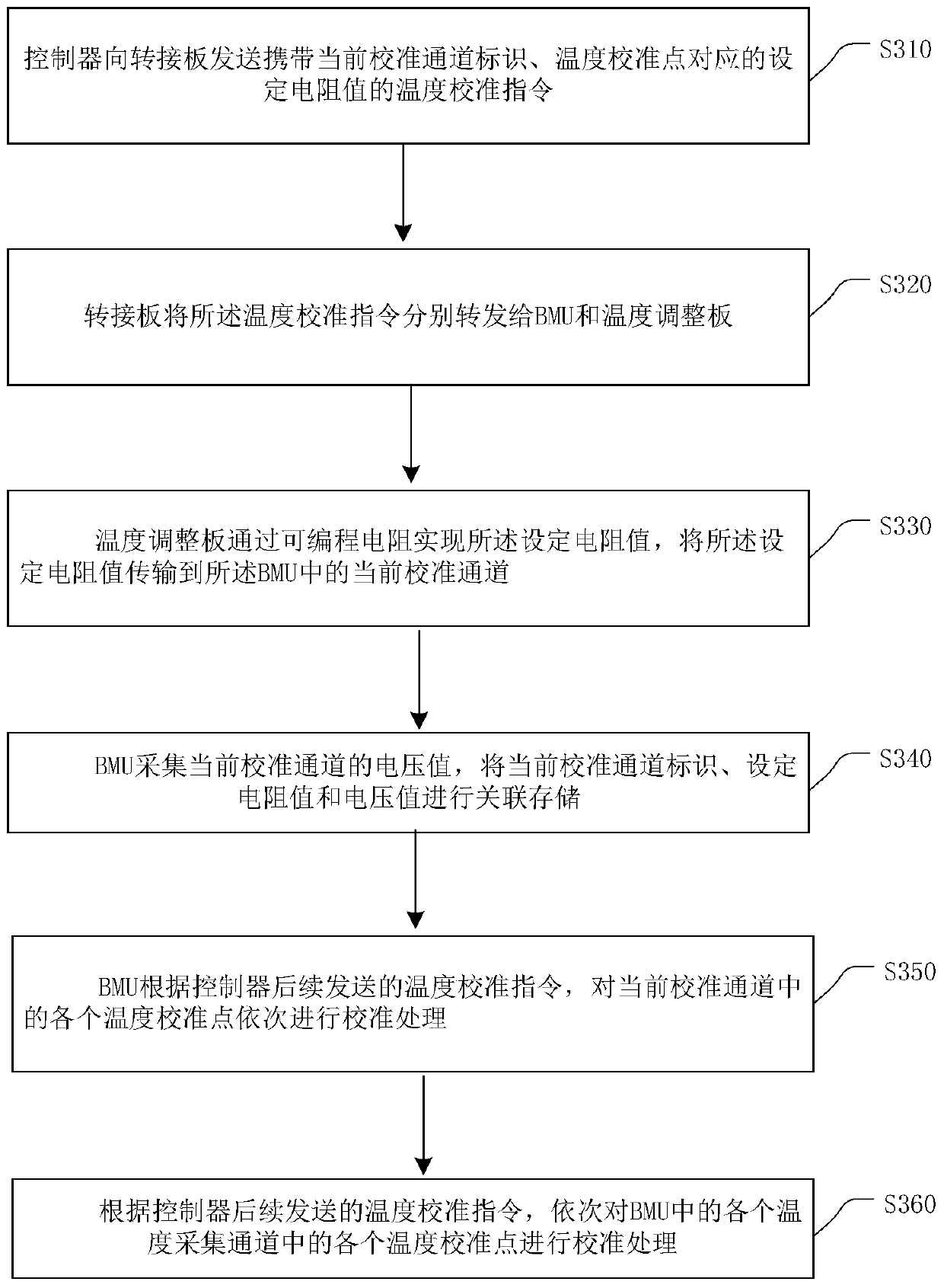

Method and device for calibrating temperature collection channel in battery management system

ActiveCN104697669AImprove Calibration AccuracyMeet calibration requirementsThermometer testing/calibrationBattery management systemsSoftware

The invention provides a method and a device for calibrating a temperature collection channel in a battery management system in one embodiment. The method comprises the following steps: a controller transmits a temperature calibration instruction carrying the signal of a channel calibrated at present and a set resistance value corresponding to a temperature calibration point to an adapter plate; the adapter plate forwards the temperature calibration instruction to a battery management system and a temperature adjustment panel, respectively; the temperature adjustment panel realizes the set resistance value by use of a programmable resistor and transmits the set resistance value to the channel calibrated at present in the battery management system; the battery management system acquires the voltage value of the channel calibrated at present, and saves the sign of the channel calibrated at present, the set resistance value and the voltage value in a correlation manner. According to the method in the embodiment, the controller and the programmable resistor network are used for sequentially and automatically calibrating multiple branches of temperature sensors by use of software, and the process is free from manual operation; the calibration accuracy is high and greatly higher than the NTC accuracy, and the calibration requirements of the BMU temperature collection channel can be completely met.

Owner:BEIJING ELECTRIC VEHICLE

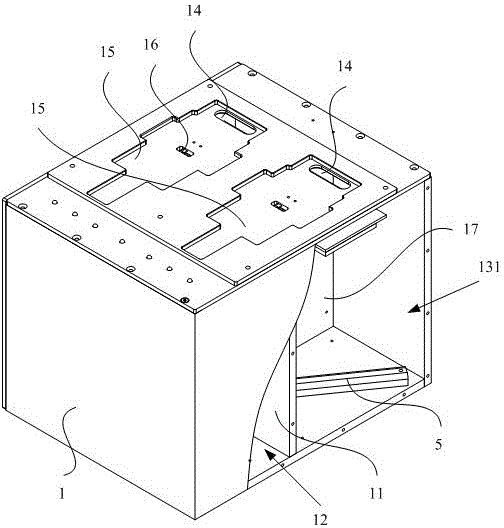

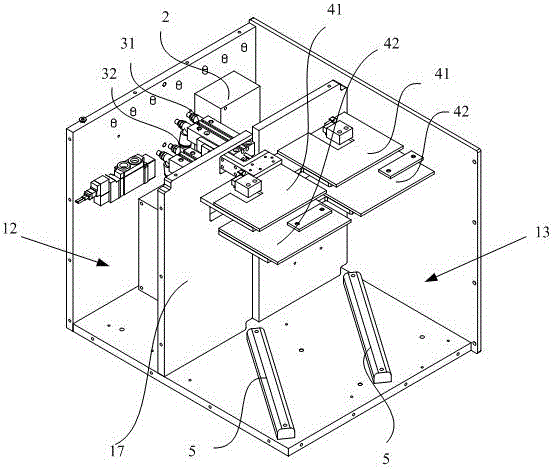

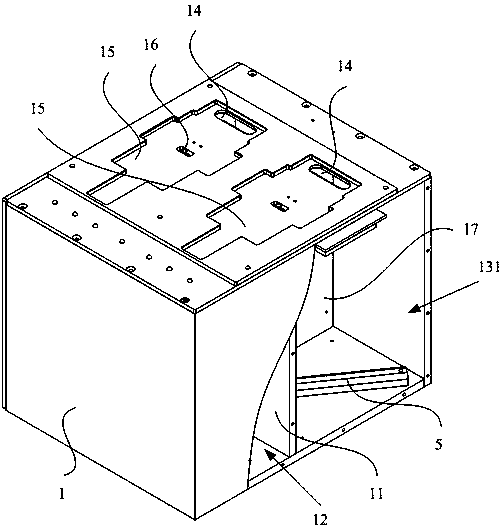

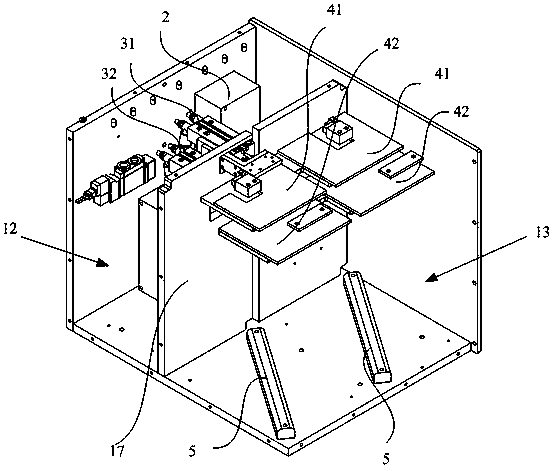

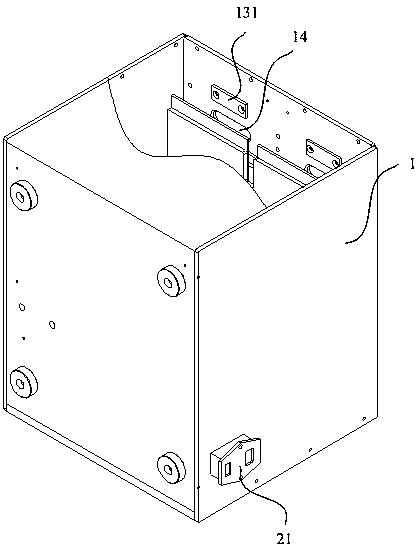

Intelligent manufacturing calibrating device for sensor, and calibrating method thereof

ActiveCN105897987AImprove test consistency and precisionLight intensity remains consistentSubstation equipmentLight sourcePiston rod

The invention provides an intelligent manufacturing calibrating device for a sensor, and a calibrating method thereof. The intelligent manufacturing calibrating device for a sensor includes a housing, a control panel, a cylinder assembly, a gray plate assembly and a light source, wherein a separator plate is arranged in the housing, and separates the internal of the housing into an installation room and a detection darkroom; the cylinder assembly includes a first cylinder and a second cylinder which are fixed in the installation room; the gray plate assembly includes a first gray plate and a second gray plate which are arranged in the detection darkroom; the first gray plate is connected with a piston rod of the first cylinder; the second gray plate is connected with a piston rod of the second cylinder; the first gray plate is arranged above the second gray plate; the top of the housing is also provided with a test through hole which communicates with the detection darkroom; the light source is arranged in the detection darkroom; a solenoid valve of the first cylinder and a solenoid valve of the second cylinder are connected with the control panel; the light source is also connected with the control panel; and the top wall of the detection darkroom is also provided with a calibration optical sensor. Therefore, the universality and the calibrating accuracy of the intelligent manufacturing calibrating device for a sensor can be improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

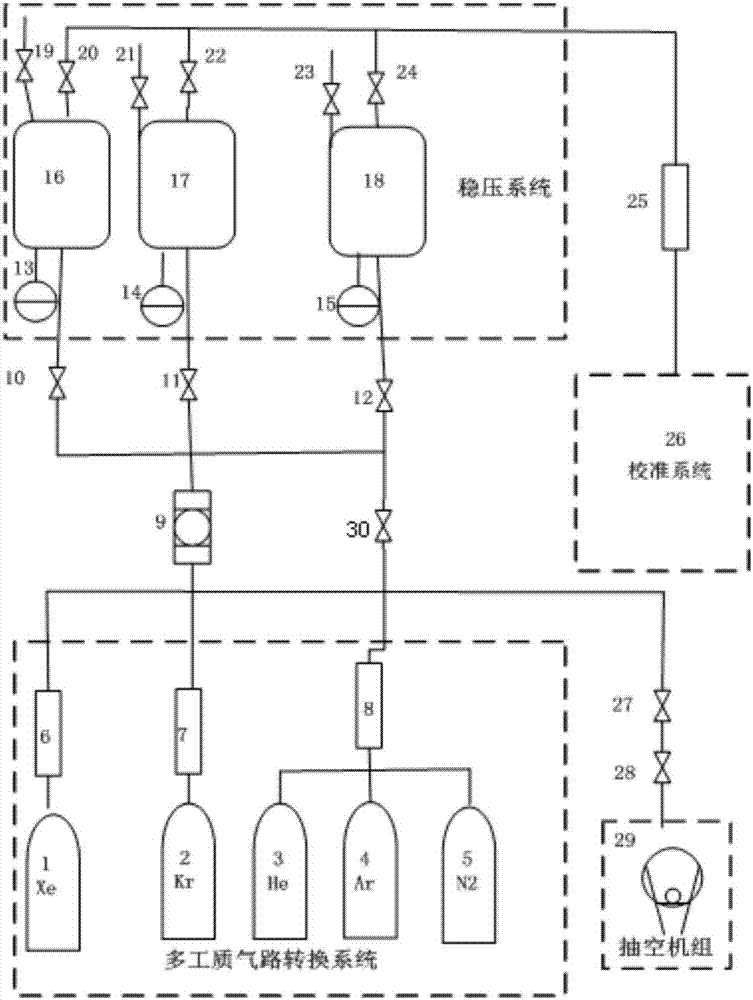

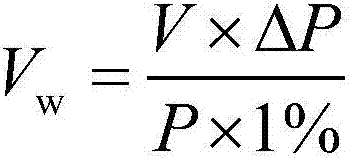

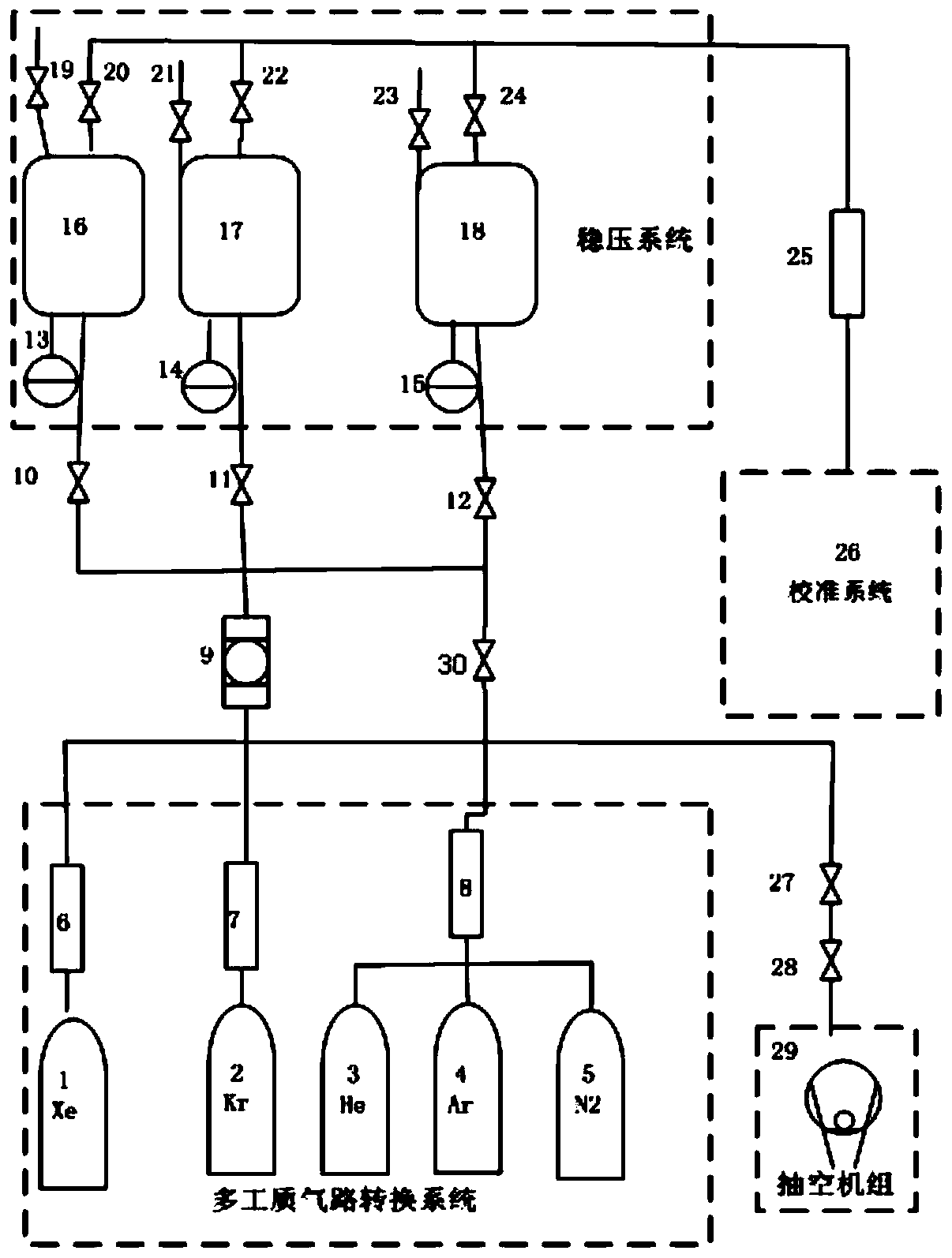

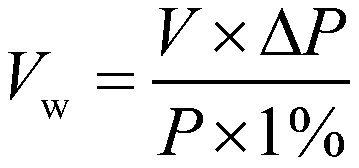

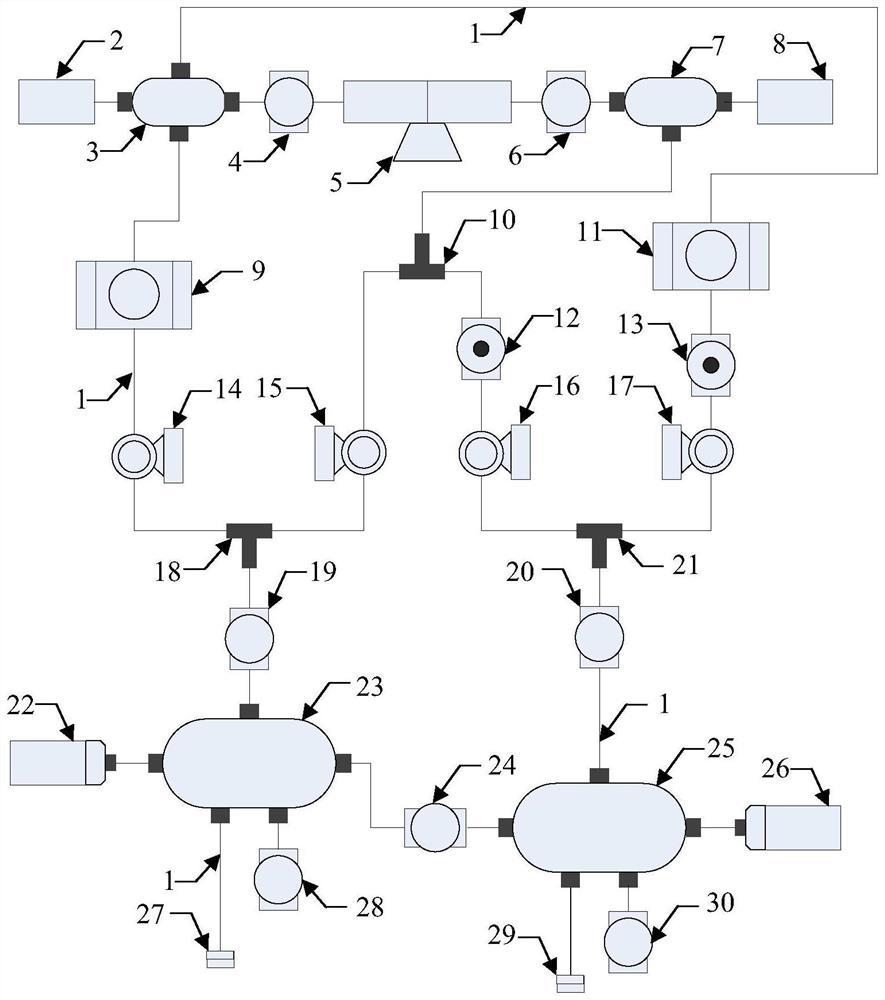

Gas supply device and method for multi-working-medium gas micro-flow calibration

ActiveCN107355681AAccurate CalibrationIn line with actual working conditionsPipeline systemsCalibration gasGas cylinder

The invention discloses a gas supply device and method for multi-working-medium gas micro-flow calibration. According to the gas supply device, a gas storage system formed by connecting a plurality of high-pressure gas bottles in parallel is used for providing multiple calibration gases, and the calibration gases conforming to the working medium actual gas can be provided. Through an electrical path converter and a pressure stabilizing system, the inlet and outlet pressure of the calibration gases is ensured, the pressure of the provided calibration gases is consistent with the actual pressure of the working medium gas, the actual work condition is better met, and working medium gas micro-flow calibration is more accurate. By means of the gas supply device and method, the calibration gases conforming to the working medium actual gas can be provided, and meanwhile the pressure of the provided calibration gases is consistent with the actual pressure of the working medium gas; and the gas supply method is simple, feasible and easy to operate.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Calibration device of multi-type three-directional acceleration sensor

InactiveCN107741508AHigh precisionSimple structureTesting/calibration of speed/acceleration/shock measurement devicesVibration measurementEngineering

The invention provides a calibration device of a multi-type three-directional acceleration sensor, and relates to the technical field of engine vibration test. The calibration device comprises a standard vibration source, an adapter bracket and an adapter screw, wherein the adapter bracket comprises four studs, is fixed on the standard vibration source through the second stud at a lower center, and is connected with a three-directional acceleration sensor through the first stud on the upper end surface and the third and fourth studs with mutually vertical central axes on two side end surfaces,so as to realize calibration in three directions of the three-directional acceleration sensor in turn. The calibration device of the multi-type three-directional acceleration sensor, provided by theinvention, solves the problem of the prior art that a standard vibration source only can calibrate high-frequency frequency response in one direction of one type of three-directional acceleration sensor, and ensures high-frequency frequency response in three directions of the three-directional acceleration sensor, so as to guarantee the precision of vibration measurement of the three-directional acceleration sensor.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Optical system for optical axis calibration and optical axis calibration method

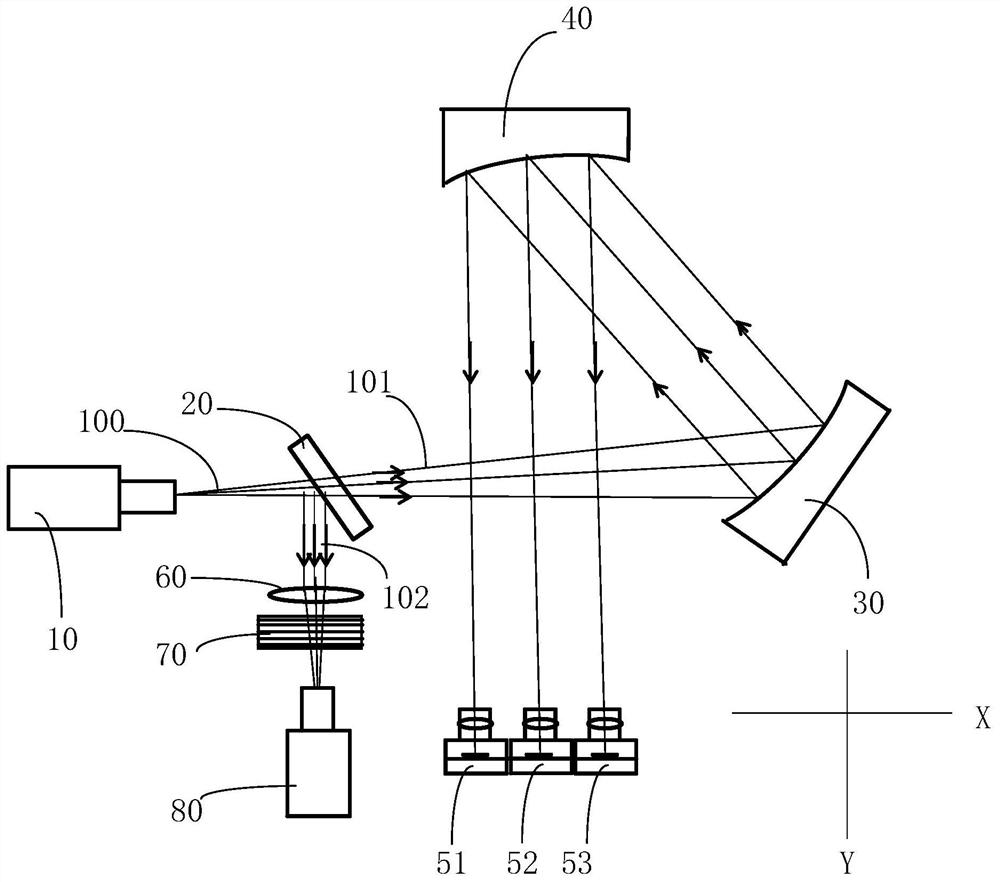

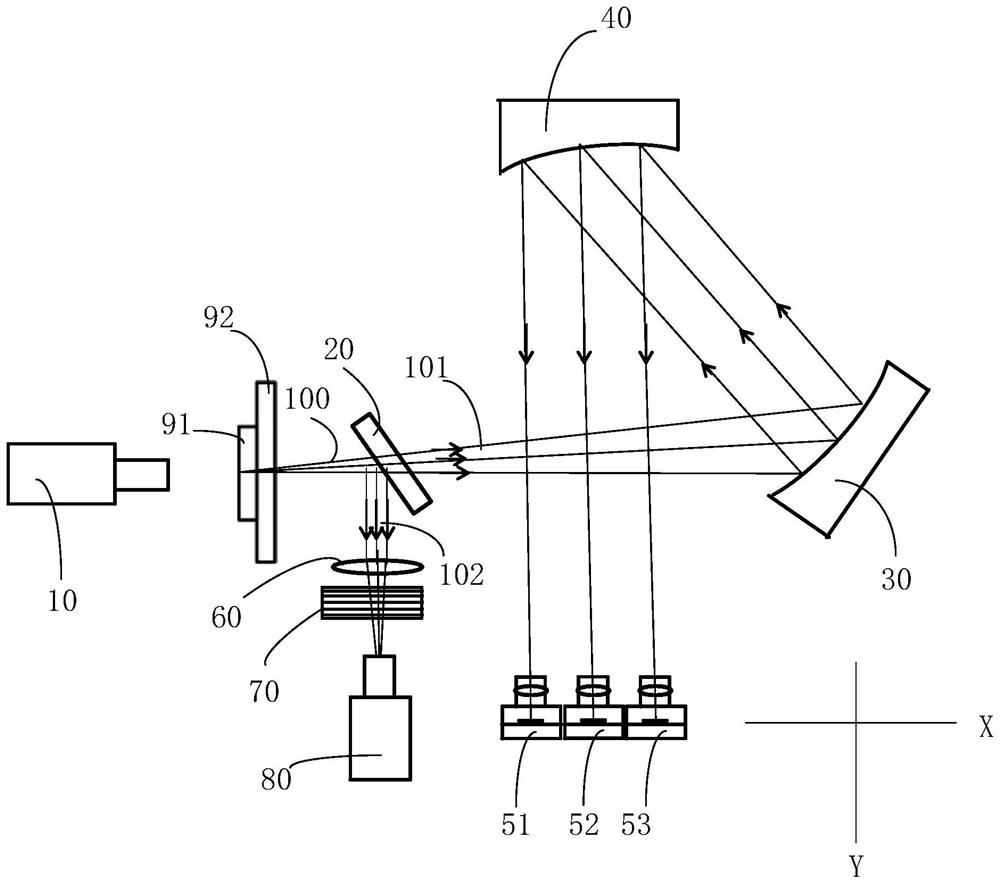

PendingCN113050292AMeet calibration requirementsSolving Consistency IssuesOptical elementsBeam splitterOptical axis

The invention provides an optical system for optical axis calibration and a optical axis calibration method. The optical system comprises a light source, a spectroscope, a first reflector, a second reflector and a detection assembly, wherein the light source, the spectroscope and the first reflector are sequentially arranged on a first straight line, the light source emits light beams towards the spectroscope, the second reflector is opposite to the first reflector, the detection assembly and the spectroscope are arranged on a second straight line, and the first straight line intersects with the second straight line; the light source emits a light beam which passes through the spectroscope to form a first light beam, and the first light beam is reflected by the spectroscope to form a second light beam; the first light beam is reflected by the first reflecting mirror and the second reflecting mirror in sequence to enter the camera module; the second light beam enters the detection assembly, and the first light beam and the second light beam have a uniquely determined corresponding relation; and the optical system is adjusted to enable the angle of the first light beam to meet the calibration requirement, and the optical axis of the camera module is set to coincide with the first light beam to realize optical axis calibration of the camera module.

Owner:O FILM IMAGE TECH (GUANGZHOU) CO LTD

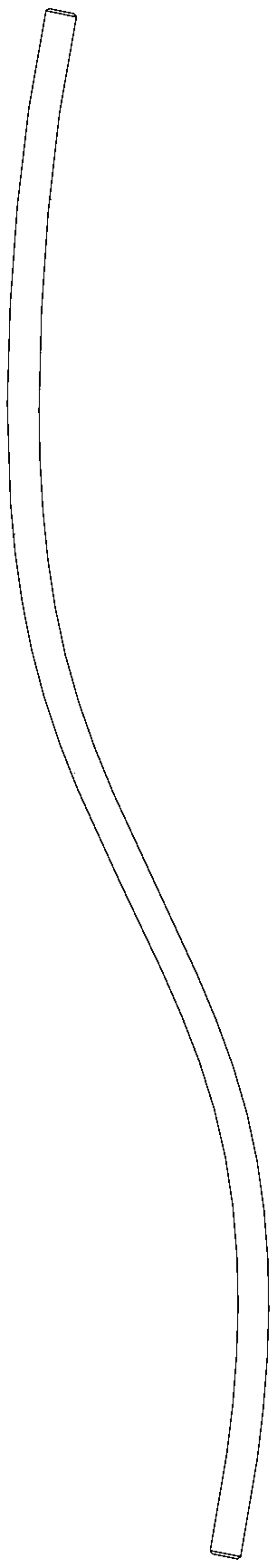

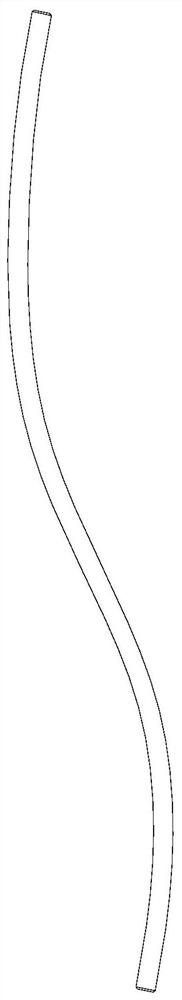

A personalized spinal orthopaedic rod and a manufacturing method thereof

ActiveCN109124763AGood orthopedic effectOrthopedic Effect GuaranteeInternal osteosythesisComputer-aided planning/modellingHuman bodySpinal column

The invention relates to the field of medical devices, in particular to a personalized spinal orthopaedic rod and a manufacturing method thereof. The method comprises the following steps: S1, acquiring the related data of the patient; S2, data comparison: comparing the related data of the patient with the data of the normal human skeleton to obtain the closest normal spinal column image; S3, making a personalized spine orthopaedic bar according to the closest normal spine image. According to the manufacturing method of the personalized spinal orthopaedic bar, the related data of the patient and the skeletal data of the normal human body are compared, so that the spinal orthopaedic bar manufactured is more suitable for the physical condition of the patient, and the orthopaedic effect of theorthopaedic bar obtained by the manufacturing method of the present application is better than that of the orthopaedic bar controlled by experience. The invention solves the problems that the shape of the orthopaedic rod depends on the empirical control and the orthopaedic effect is poor in the prior art.

Owner:CHUANGHUI MEDICAL EQUIP JIANGSU

A personalized spinal orthopedic rod and its manufacturing method

ActiveCN109124763BGood orthopedic effectOrthopedic Effect GuaranteeInternal osteosythesisComputer-aided planning/modellingSpinal columnHuman body

The invention relates to the field of medical devices, in particular to a personalized spinal orthopaedic rod and a manufacturing method thereof. The method comprises the following steps: S1, acquiring the related data of the patient; S2, data comparison: comparing the related data of the patient with the data of the normal human skeleton to obtain the closest normal spinal column image; S3, making a personalized spine orthopaedic bar according to the closest normal spine image. According to the manufacturing method of the personalized spinal orthopaedic bar, the related data of the patient and the skeletal data of the normal human body are compared, so that the spinal orthopaedic bar manufactured is more suitable for the physical condition of the patient, and the orthopaedic effect of theorthopaedic bar obtained by the manufacturing method of the present application is better than that of the orthopaedic bar controlled by experience. The invention solves the problems that the shape of the orthopaedic rod depends on the empirical control and the orthopaedic effect is poor in the prior art.

Owner:CHUANGHUI MEDICAL EQUIP JIANGSU

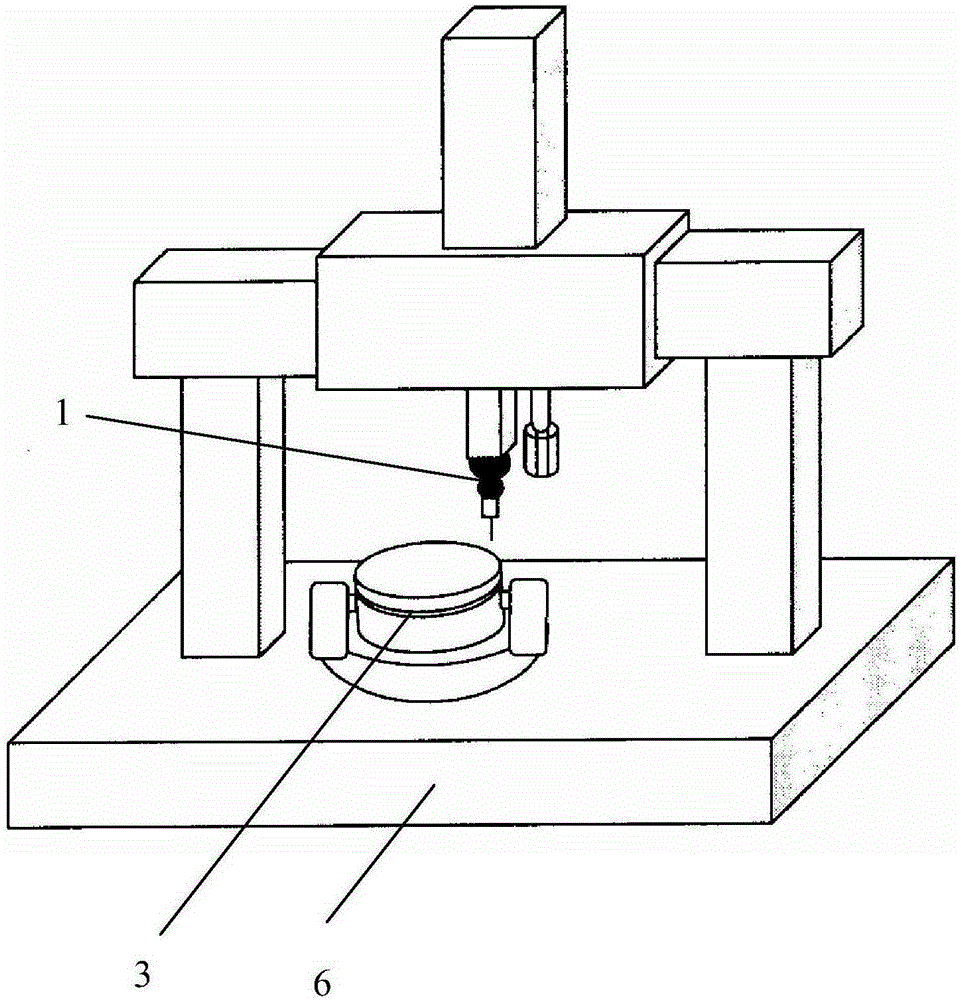

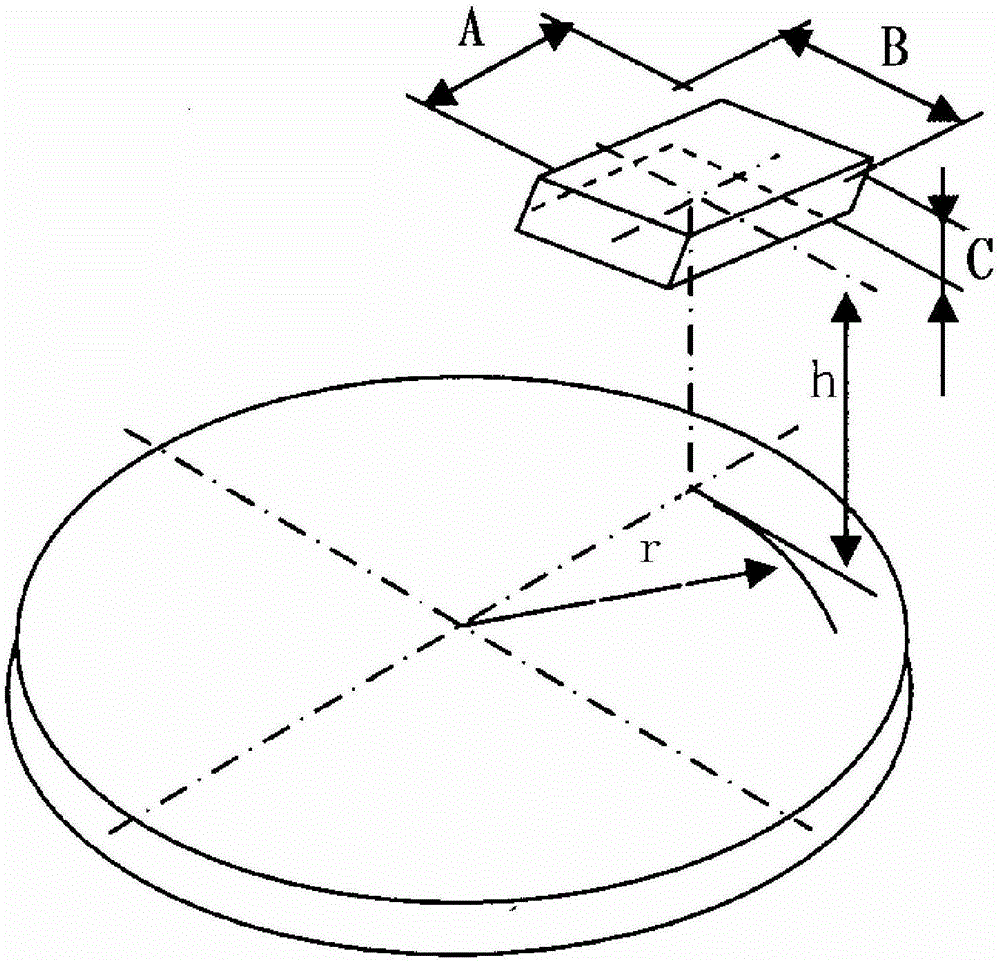

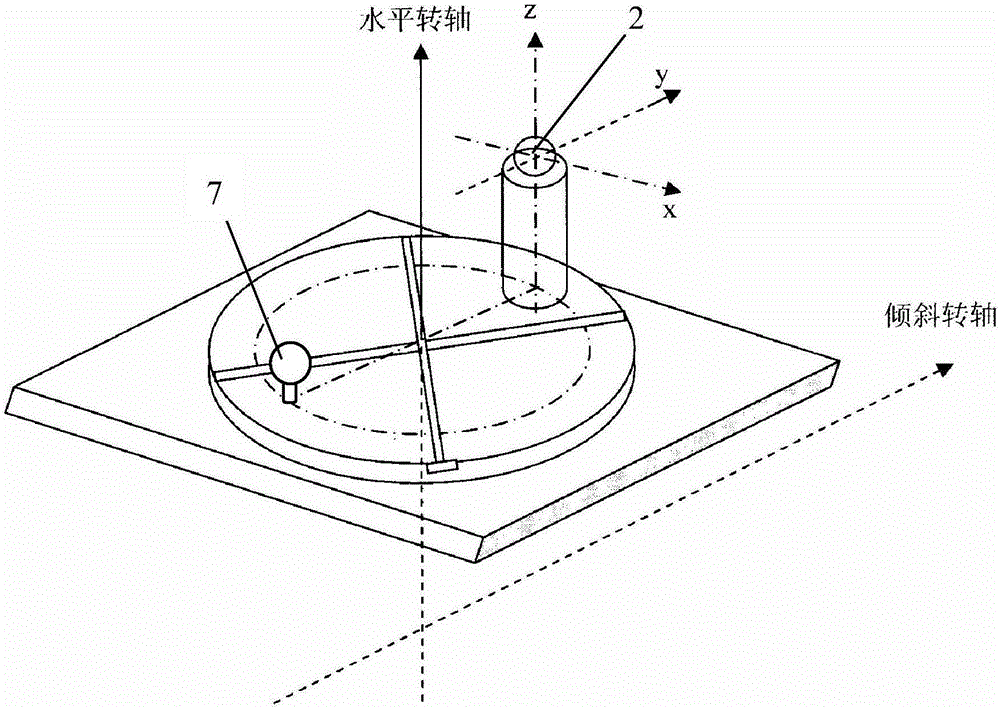

A Comprehensive Error Calibration Method for Five Coordinate Measuring Machine

ActiveCN103591913BRealize detectionGuarantee the quality of inspectionMeasurement devicesCoordinate-measuring machineComputer science

The invention relates to the field of calibration of coordinate measuring machines, in particular to a method for calibrating comprehensive errors of a five-coordinate measuring machine. The method aims to meet the requirement that a calibration mode is consistent with an actual detection mode, correctly analyze the influence of five-axis comprehensive errors on detection parts, and meet the requirement of traceability of values. Space five-axis comprehensive error calibration is achieved by reasonably establishing a coordinate system, designing and determining calibration space theory positions and formulating a calibration path. On the basis of a comprehensive accuracy calibration technology of a four-axis coordinate measuring machine, a scheme and steps of comprehensive accuracy calibration of the five-axis (two rotation axes and three coordinate axes) measuring machine are developed and designed, the appropriate coordinate system, the calibration scheme and the calibration path are designed and established, the actual detection of theoretical positions is achieved by determining the theoretical positions of the center of a standard detection sphere in measurement space, comprehensive error values of the five-coordinate measuring machine are obtained through the comparison of theoretical values with measured values, and the requirement that the calibration mode is consistent with the actual detection mode is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

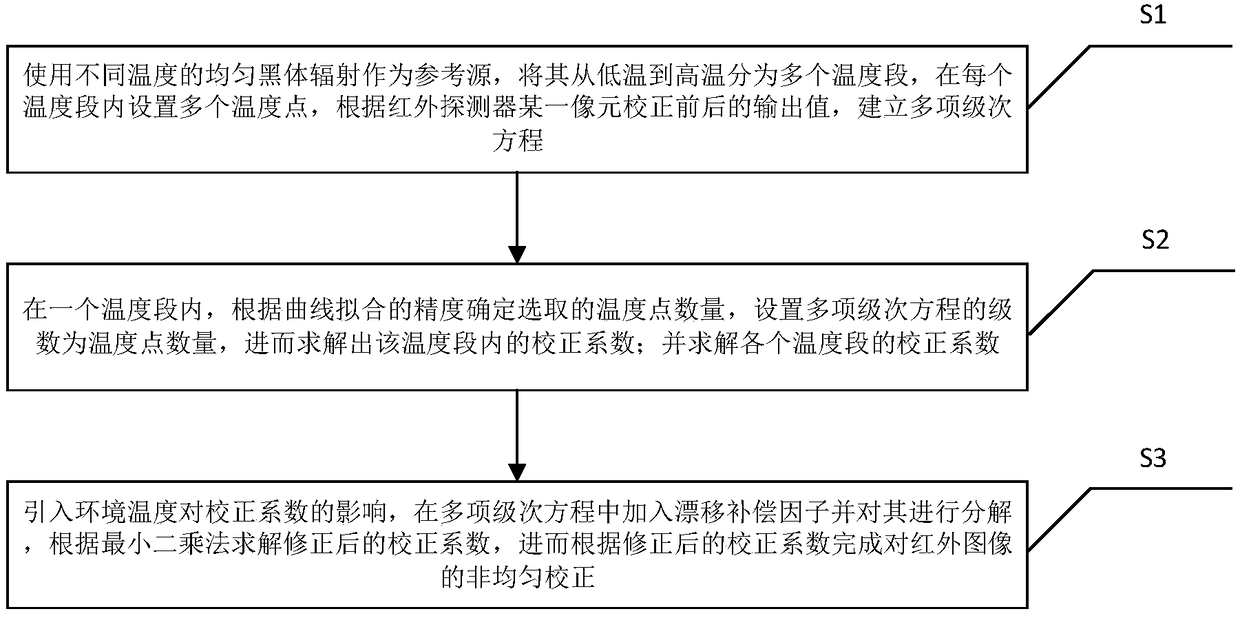

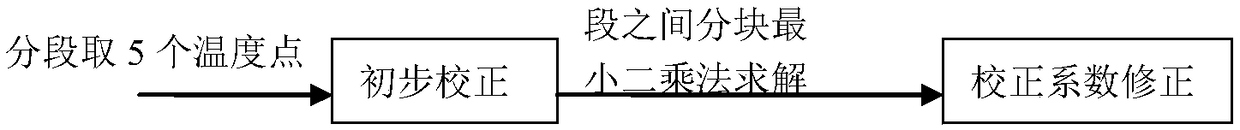

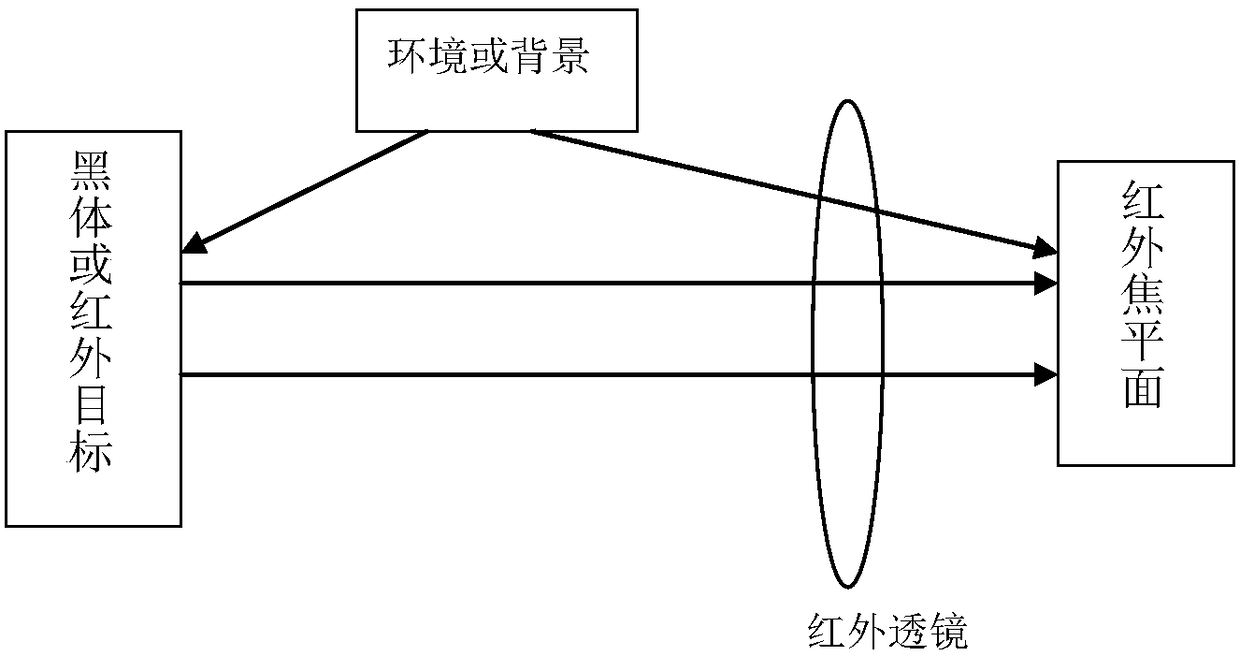

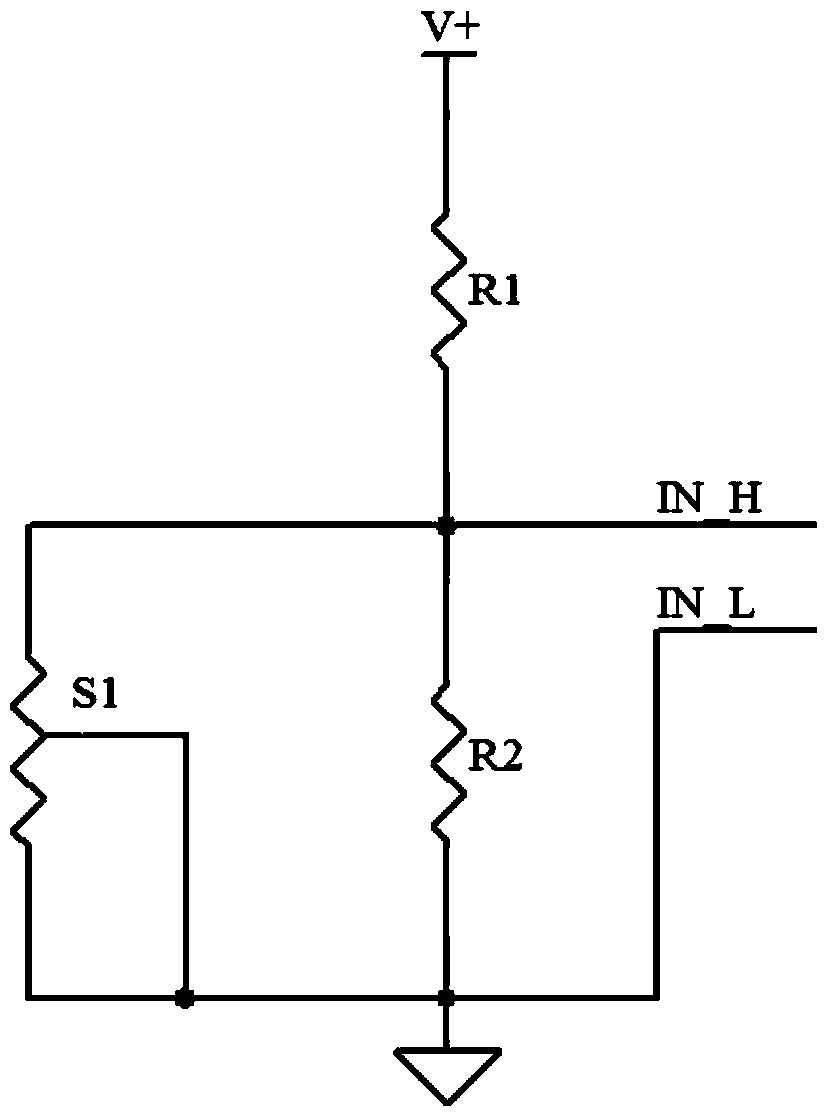

Image calibration method and system under wide temperature range conditions

ActiveCN106197690BMeet calibration requirementsMeet the requirements of non-uniformity correctionRadiation pyrometryBlack-body radiationDecomposition

The invention discloses an image calibration method and system under wide temperature range conditions. The method includes the following steps: S1. Using uniform black body radiation at different temperatures as a reference source, dividing it into multiple temperature sections from low temperature to high temperature, Set multiple temperature points in each temperature segment, and establish multiple order equations according to the output value of a certain pixel of the infrared detector before and after correction; S2. In a temperature segment, determine the selected one according to the accuracy of curve fitting The number of temperature points, and then solve the correction coefficient in the temperature section; and solve the correction coefficient of each temperature section; S3, add the drift compensation factor to the multi-level equation and decompose it, and solve the correction according to the least square method Correction coefficient, and then complete the non-uniform correction of the infrared image. The invention can meet the requirement of non-uniformity correction of infrared image in large dynamic range, and eliminate the problem of image noise caused by non-uniformity.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

Method and device for calibrating temperature acquisition channel in battery management system

ActiveCN104697669BMeet calibration requirementsNo manual operationThermometer testing/calibrationPatch panelElectrical resistance and conductance

Embodiments of the present invention provide a method and device for calibrating a temperature acquisition channel in a battery management system. The method includes: the controller sends a temperature calibration instruction carrying the current calibration channel identifier and the set resistance value corresponding to the temperature calibration point to the adapter board, and the adapter board forwards the temperature calibration instruction to the battery management system and the temperature adjustment board respectively; The adjustment board realizes setting the resistance value through the programmable resistance, and transmits the setting resistance value to the current calibration channel in the battery management system; the battery management system collects the voltage value of the current calibration channel, and sends the current calibration channel identification, setting resistance value and Voltage values are stored associatively. The embodiment of the present invention uses the controller and the programmable resistance network to automatically calibrate the multi-channel temperature sensors through software control, and the process does not require manual operation; the calibration accuracy is high, which is much higher than the NTC accuracy, and can fully meet the BMU temperature acquisition channel. calibration requirements.

Owner:BEIJING ELECTRIC VEHICLE

The synchronous position can be adjusted at will, and the image type four-wheel aligner calibration device

InactiveCN105699100BGuaranteed to drive in a straight lineMeet calibration requirementsVehicle wheel testingImage typeLarge size

The invention relates to a synchronous position randomly adjustable image type calibrating device for a four-wheel aligner, and belongs to the calibrating devices for an automobile detection device. The synchronous position randomly adjustable image type calibrating device comprises a synchronous mechanism dragging rack, a front beam zero-point test jig, a front left bench examination portion, a front right bench examination portion, a rear left bench examination portion, a rear right bench examination portion, simulating wheel hubs and four wheel clamp assemblies. The synchronous position randomly adjustable image type calibrating device overcomes the defects of large size, heavy dead weight, high assembly difficulty and low accuracy of a conventional calibrating device due to a complex structure, and ensures more accurately measuring wheel positioning parameters.

Owner:JILIN UNIV

Micro-torque sensor calibrator based on magnetic suspension effect

InactiveCN101943625BMeet calibration requirementsSimple structureForce/torque/work measurement apparatus calibration/testingEngineeringBending moment

The invention discloses a micro-torque sensor calibrator based on a magnetic suspension effect. A microtorque sensor to be calibrated is fixed on a base by a positioning block and a clasping block; a moment arm with a circular arc side is installed on a rotating shaft; the bottom surface of the base is provided with a height adjusting support pin, and a guide column and a guide rail are installedon the height adjusting support pin; a bearing frame is installed on the guide rail, the edge of the bearing frame is slotted, and a micro-bearing is installed in a groove; a lead penetrates through the groove on the bearing frame and is hung on the micro-bearing, one end is fixed at the circular arc sides at both ends of the moment arm, and a weight is hung on the other end; a magnetic seat is installed on the guide column; and the central position of the moment arm and the central position of the magnetic seat are respectively provided with disk-shaped magnets. The invention can eliminate the bending moment applied to the rotating shaft of the microtorque sensor to be calibrated by moment arm weight during horizontal arrangement, realize pure torque loading, ensure that the torque is a constant value and meanwhile lead the moment arm to be in a suspension state, has the characteristics of simple structure, high precision and high stability and more favorably meets the calibrating requirement of the microtorque sensor.

Owner:台州市计量技术研究院

Refractive adjustment method and device for augmented reality equipment, augmented reality equipment

ActiveCN108490611BImprove comfortMeet calibration requirementsNon-linear opticsOptical elementsComputer graphics (images)Engineering

Owner:BOE TECH GRP CO LTD

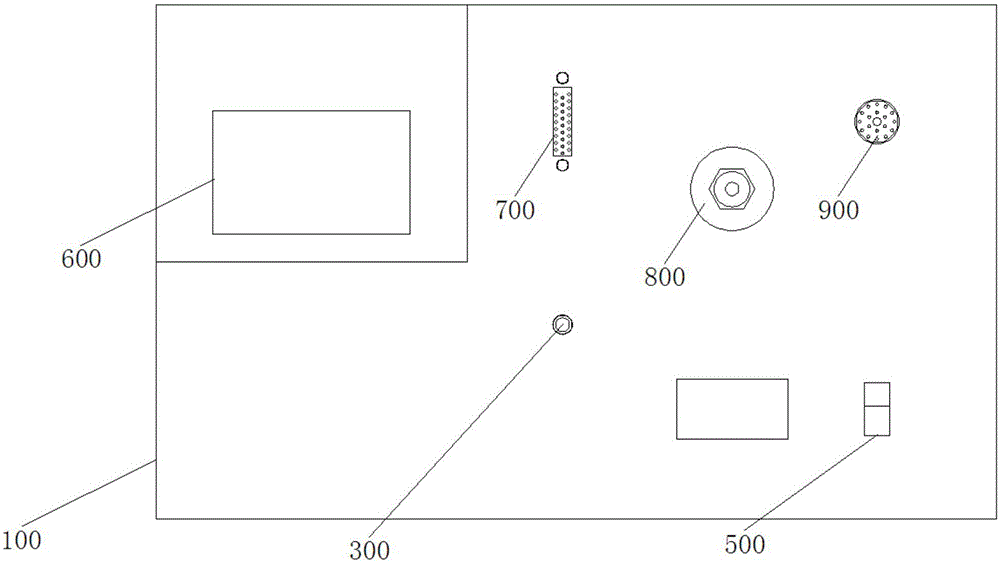

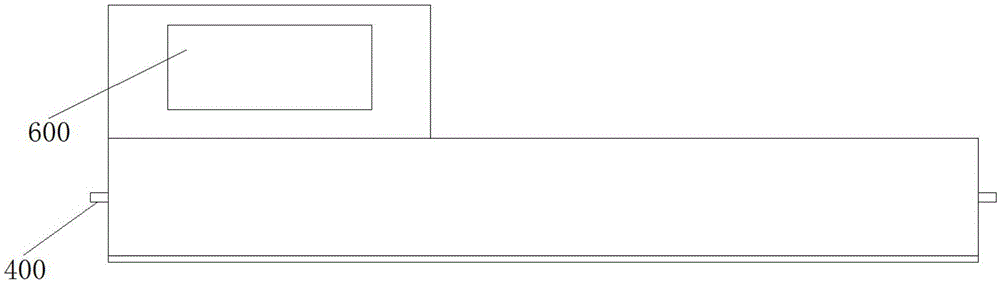

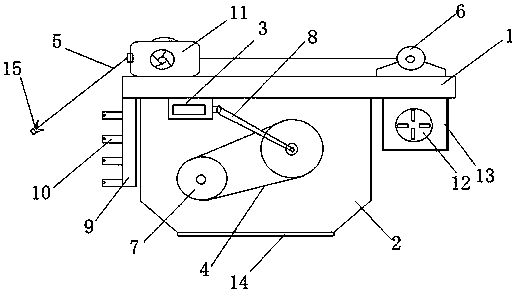

Level calibrator

InactiveCN109373969AMeet calibration requirementsHigh precisionHeight/levelling measurementIncline measurementEngineeringSurface plate

The invention discloses a level calibrator which comprises a surface plate, a base, a motor, a synchronous belt, a rope, a bearing, a locker, a take-up reel and a storage frame. The surface plate is mounted above the base; the motor, two gears, a connecting shaft and the synchronous belt are mounted in the base; the connecting shaft is mounted on the motor, the connecting shaft is connected to onegear, the two gears are driven by the synchronous belt; the bearing, the take-up reel, an auxiliary column, a fixed head and the locker are mounted on the surface plate; the bearing is located behindthe surface plate, the storage frame is mounted below the bearing, the storage frame is located at the bottom of the surface plate, the take-up reel is mounted in the storage frame, the locker is mounted at the front end of the surface plate, the auxiliary column is arranged below the locker, and the auxiliary column is located at the bottom of the surface plate. The level calibrator calibrates aplane by being stretched by the rope, so that the calibrating demand can be met quickly and simply and the calibrating precision is very high.

Owner:昆山弘义千高装饰工程有限公司

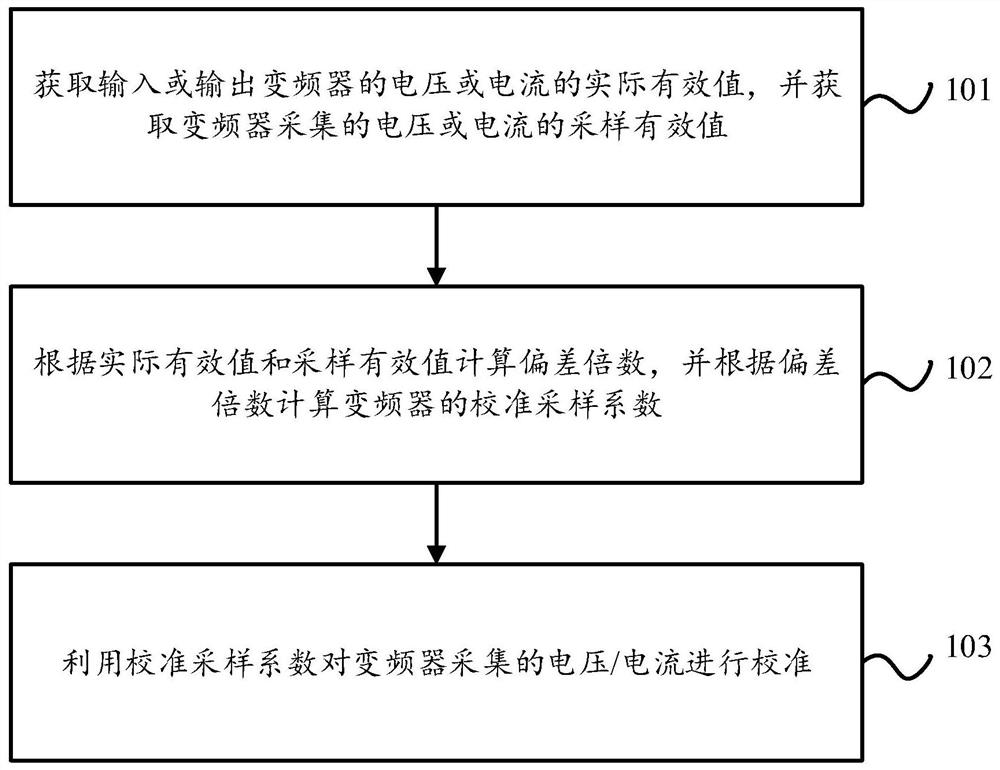

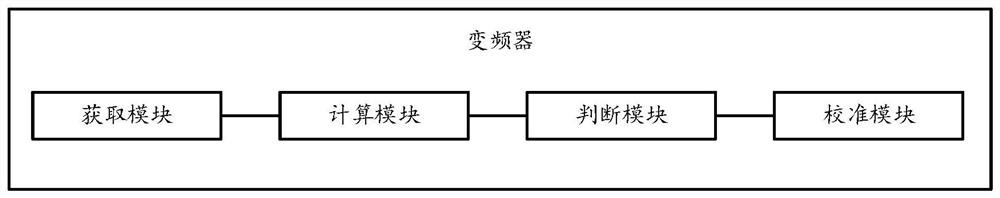

Method for calibrating voltage or current of frequency converter, frequency converter and system

ActiveCN112510973BMeet calibration requirementsAchieve calibrationPower conversion systemsFrequency changerInverter

Owner:DAYU ELECTRIC

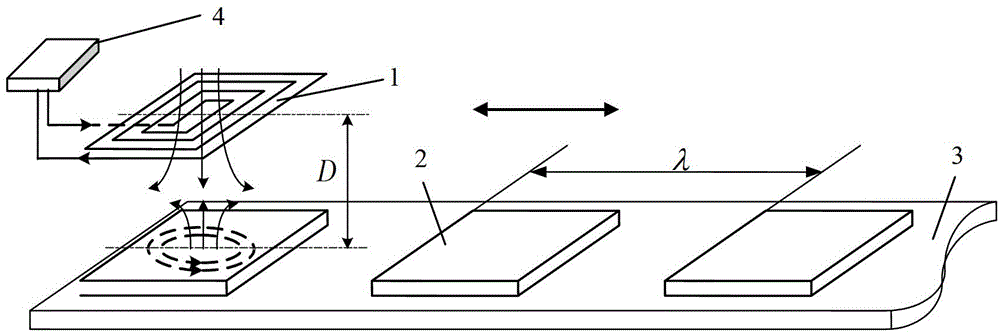

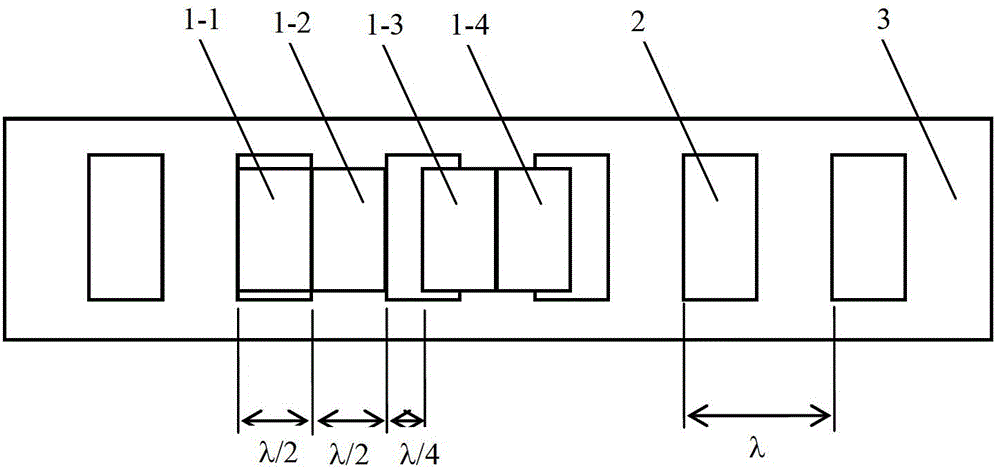

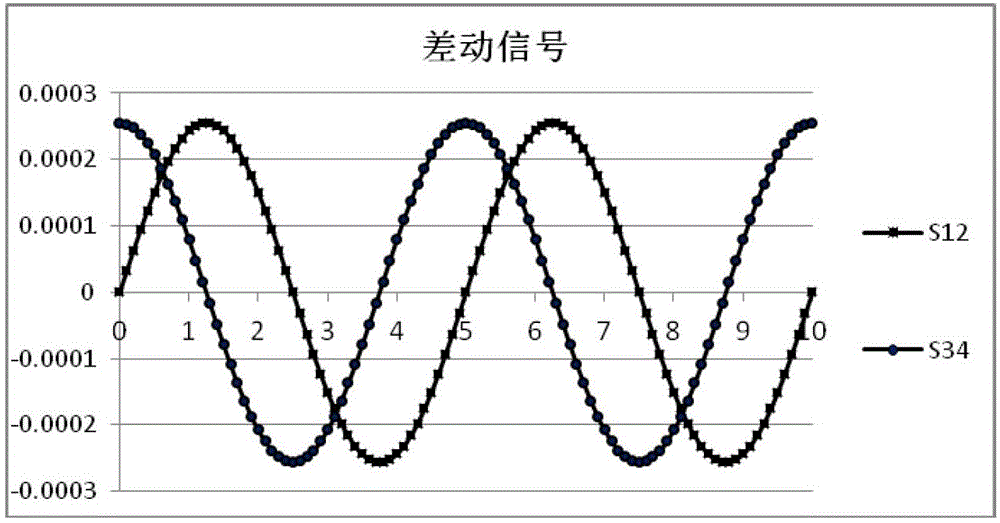

Eddy current grid sensor with self-calibration function and self-calibration method

The invention provides an eddy current grating sensor with a self-calibration function and a self-calibration method. The sensor comprises measuring coils, a reflection conductor, a substrate and a measuring circuit. The measuring coils are of multiple forms and are arranged in pairs, phase differences of each group of measuring coils are 1 / 2 of a measuring wavelength, and thus differential wave signals are formed and outputted. As long as the sensor is pulled by a section of distance, changes of signals generated through dispersiveness of electronic parts and components and manufacturing processes can be effectively recognized and detected, and normalization coefficients of the measuring coils are obtained through calculation. In the measuring process, measuring results can be automatically calibrated and corrected. The self-calibration method has the advantages of being high in speed, low in cost, good in interchangeability and needless of extra verification devices, can meet calibration requirements of mass production, and can be popularized and applied to other sensors.

Owner:SHANGHAI JIAOTONG UNIV

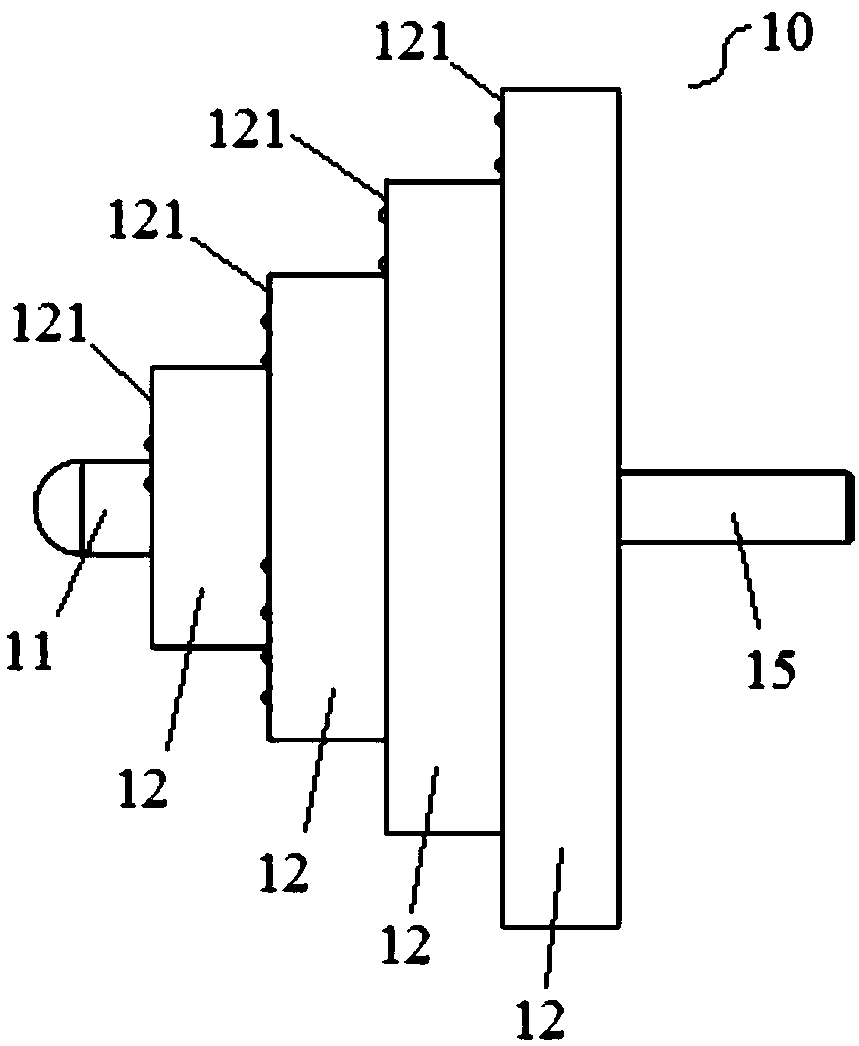

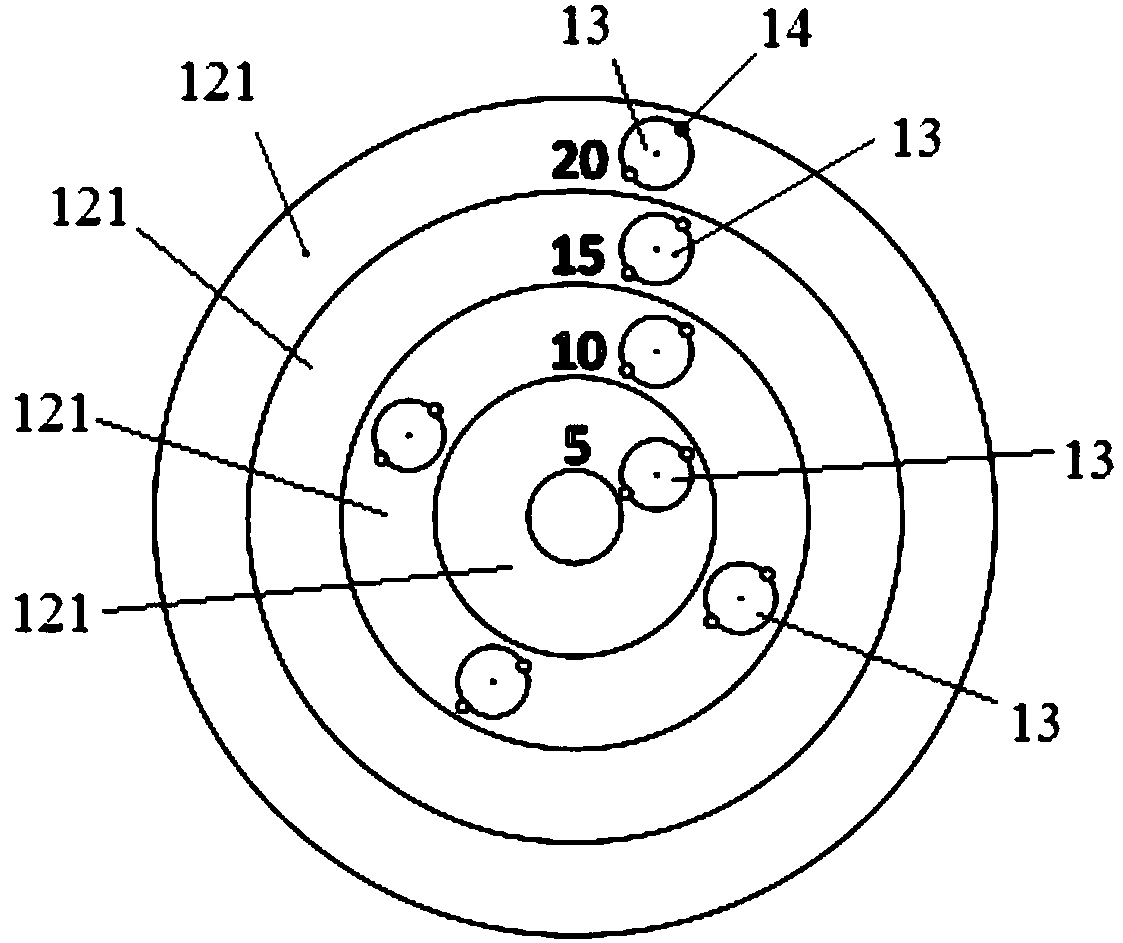

Calibration device for working distance of electron microscope

ActiveCN106783495BMeet calibration requirementsSolve the problem of working distanceElectric discharge tubesElectron microscopeScanning electron microscope

The invention provides a calibrating device for a working distance of an electron microscope. The calibrating device comprises a calibration substrate (10) for mounting on a sample stage of the electron microscope, wherein the calibration substrate (10) has a plurality of calibration planes (121) disposed along the axial direction of the calibration substrate (10) and facing an objective lens pole shoe of the electron microscope and a positioning protrusion (11) which protrudes towards the objective lens pole shoe and realizes the positioning of the calibration substrate (10) through making contact and cooperation with the objective lens pole shoe. At least three calibration holes (131) having a focusing function are arranged on at least one of the calibration planes (121) of the plurality of calibration planes (121), and when the focus of the electron microscope is constant and all the calibration holes (131) are focused at the same time, the distance from the lower surface of the objective lens pole shoe to each calibration plane (121) is the working distance set by the electron microscope. The technical scheme of the present invention effectively solves the problem that no calibrating device in the prior art is used to scan the working distance of the electron microscope.

Owner:KYKY TECH

A gas supply device and gas supply method for multi-working medium gas micro-flow calibration

ActiveCN107355681BAccurate CalibrationIn line with actual working conditionsPipeline systemsCalibration gasGas cylinder

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

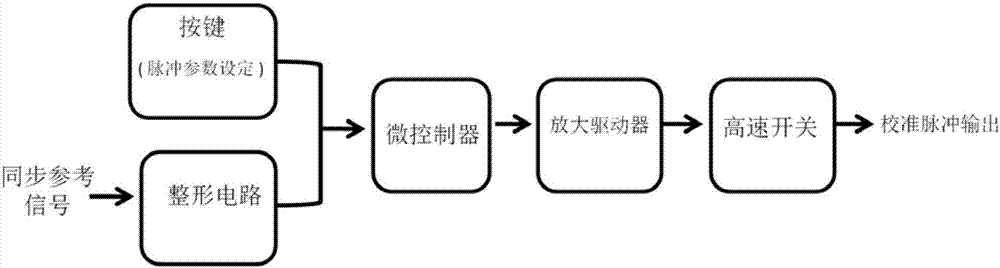

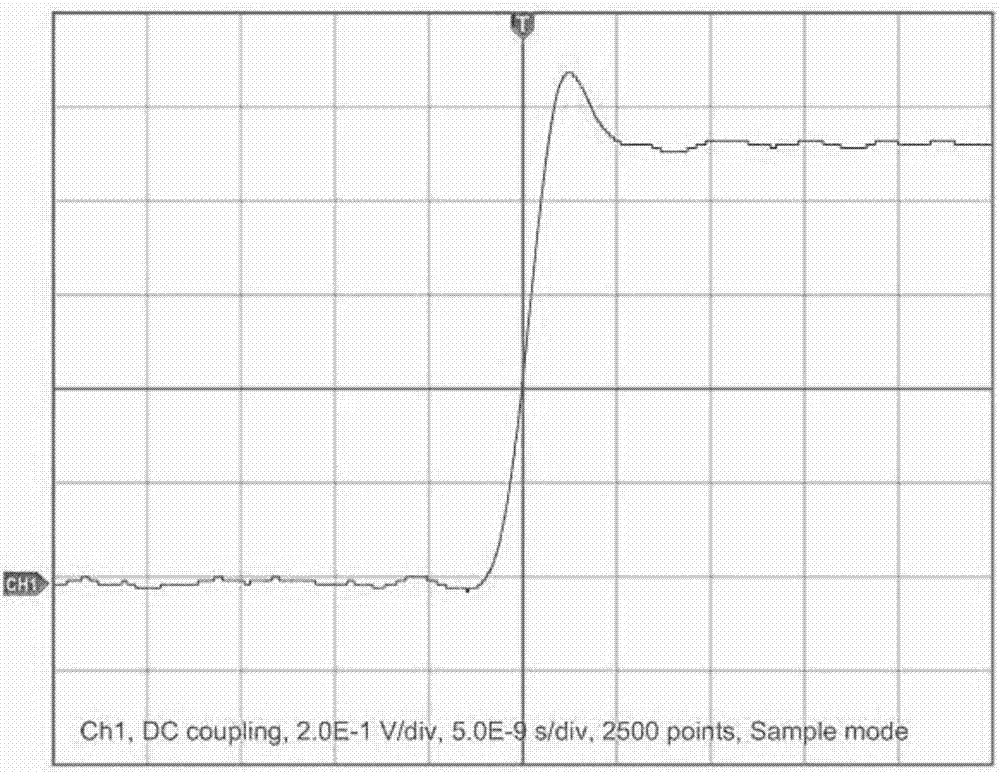

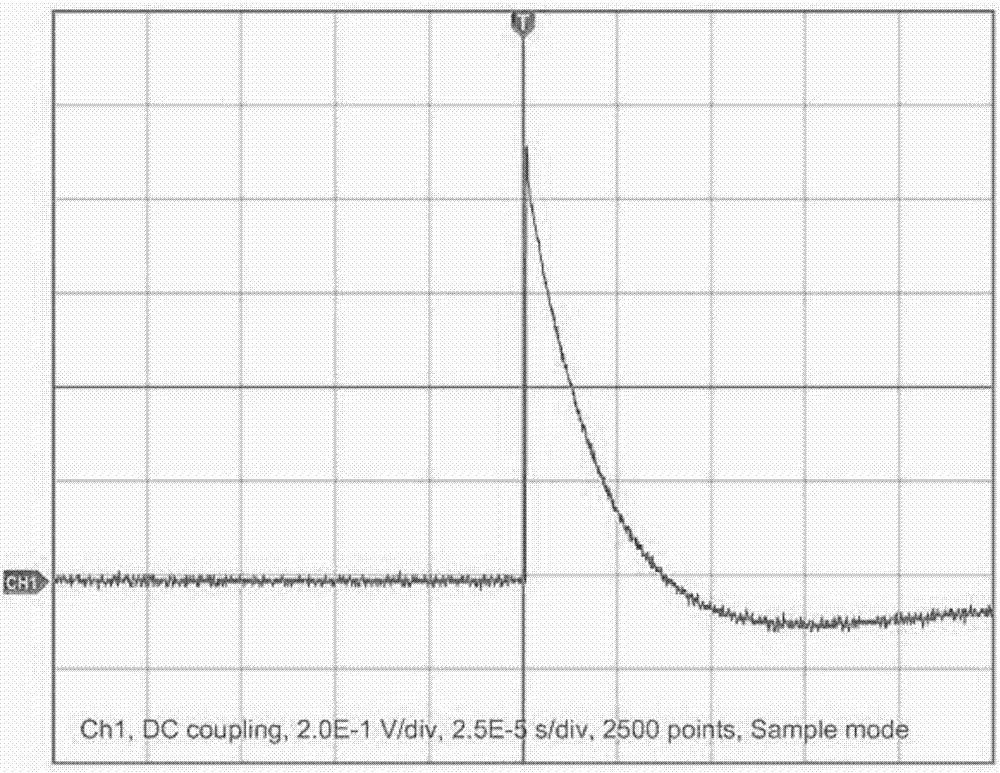

Method for generating calibration pulses for detecting partial discharges in high voltage equipment

ActiveCN103809089BMeet calibration requirementsSimulate the realTesting dielectric strengthMicrocontrollerMeasurement device

The invention relates to a method and a device for generating a partial discharge calibration pulse of high-voltage electric equipment, and belongs to the technical field of high-voltage equipment monitoring. Set the amplitude and repetition frequency of the calibration pulse through the external port. The amplitude of the set calibration pulse is read by the microcontroller and converted into the corresponding internal set value. According to the set value, the microcontroller controls the digital-to-analog converter to output a corresponding low-voltage DC analog signal, and amplifies it into a high-voltage DC analog signal through a precision amplifier. The microcontroller generates a control signal, drives a high-speed switch, outputs a high-voltage DC signal with a specific width, and then turns it off quickly, thereby generating a pulse for partial discharge calibration. The timing of the output pulse is controlled by the microcontroller according to the zero-crossing point of the reference signal. The method greatly improves the steepness of the calibration pulse and expands the output range of the pulse amplitude. It will play an important role in off-line measurement of partial discharge, live detection, on-line monitoring and fault diagnosis of high-voltage power equipment.

Owner:GUANGDONG POWER GRID CO LTD +1

Dual-channel atmospheric parameter pressure control gas circuit and adjusting method

PendingCN113867433AIncrease or decrease massLittle influence on control speedFluid pressure measurementFluid pressure control using electric meansAir pumpEngineering

The invention discloses a dual-channel atmospheric parameter pressure control gas circuit and an adjusting method, and belongs to a static pressure measurement calibration instrument. The device comprises a pressure sensor and a pressure component which are sequentially connected through a pipeline to form three main parts which are an air source system, a static pressure channel and a full pressure channel, and a static pressure channel pressure output interface and a full pressure channel pressure output interface are respectively led out and used for being connected with a calibrated atmospheric parameter instrument. In the pressure adjusting process, initial pressure is provided through a pressure / vacuum integrated air pump, the initial pressure is adjusted to the fixed pressure through a reasonably-arranged pressure reducer, the flow of gas entering and discharging the system is controlled through a flow adjusting valve, the opening and closing time of a channel where a stop valve is located is controlled through the stop valve, and finally accurate pressure control is achieved. A flow control mode is adopted for double-channel pressure control, gas pressure control is achieved by increasing or reducing the mass of gas in the closed containing cavity, the situation that a calibrated object has the large load volume can be handled, and the influence on the control speed is small.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Sensor intelligent manufacturing calibration device and calibration method thereof

ActiveCN105897987BImprove versatilityMeet calibration requirementsSubstation equipmentSolenoid valveBiochemical engineering

The invention provides an intelligent manufacturing calibrating device for a sensor, and a calibrating method thereof. The intelligent manufacturing calibrating device for a sensor includes a housing, a control panel, a cylinder assembly, a gray plate assembly and a light source, wherein a separator plate is arranged in the housing, and separates the internal of the housing into an installation room and a detection darkroom; the cylinder assembly includes a first cylinder and a second cylinder which are fixed in the installation room; the gray plate assembly includes a first gray plate and a second gray plate which are arranged in the detection darkroom; the first gray plate is connected with a piston rod of the first cylinder; the second gray plate is connected with a piston rod of the second cylinder; the first gray plate is arranged above the second gray plate; the top of the housing is also provided with a test through hole which communicates with the detection darkroom; the light source is arranged in the detection darkroom; a solenoid valve of the first cylinder and a solenoid valve of the second cylinder are connected with the control panel; the light source is also connected with the control panel; and the top wall of the detection darkroom is also provided with a calibration optical sensor. Therefore, the universality and the calibrating accuracy of the intelligent manufacturing calibrating device for a sensor can be improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com