Method and device for calibrating temperature collection channel in battery management system

A battery management system and channel technology, applied in the field of calibration of the temperature acquisition channel in the battery management system, can solve the problems of difficult adjustment, time-consuming and laborious, sliding rheostat deviation, etc., and achieve the effect of high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

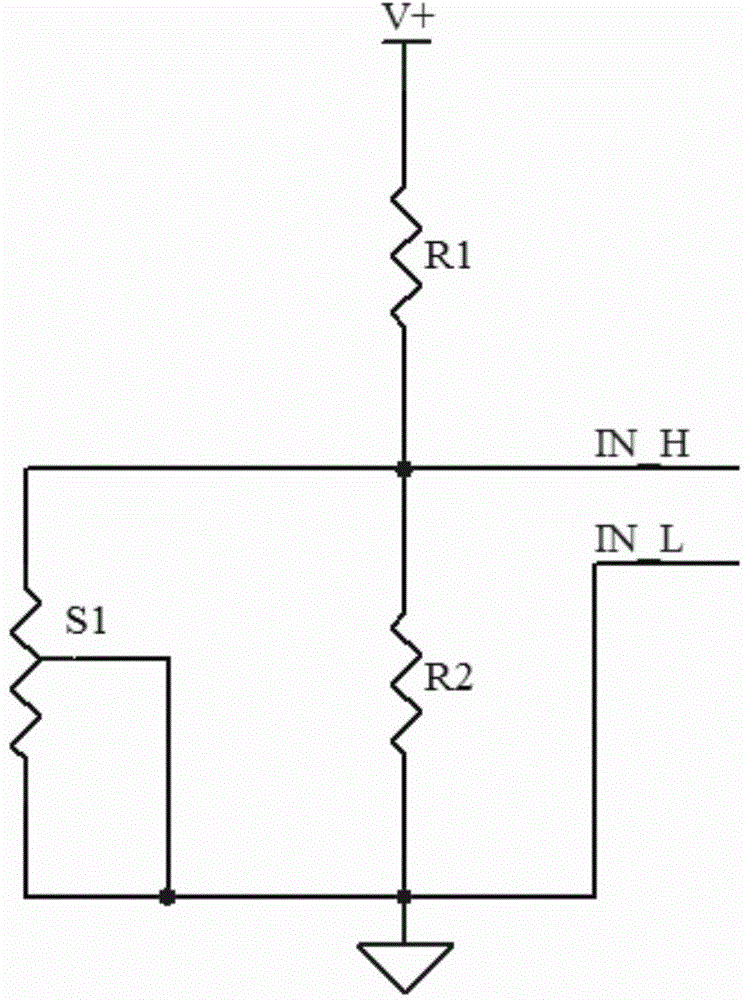

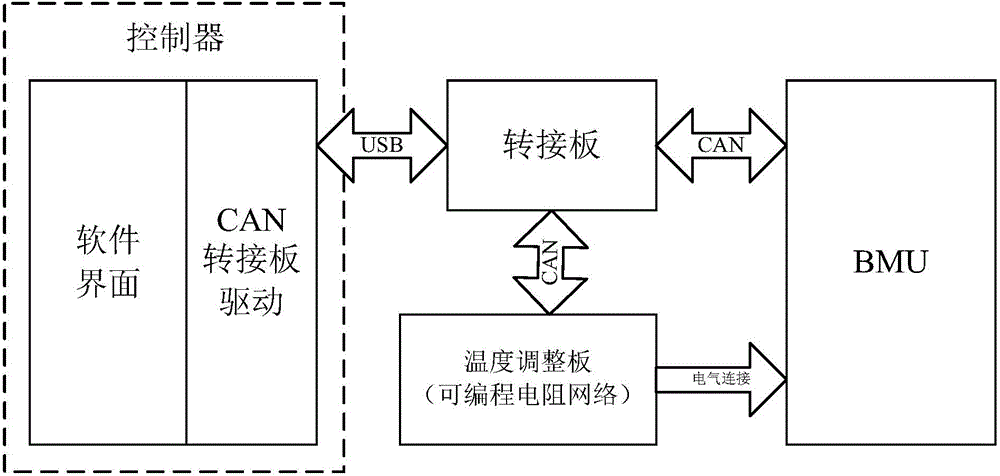

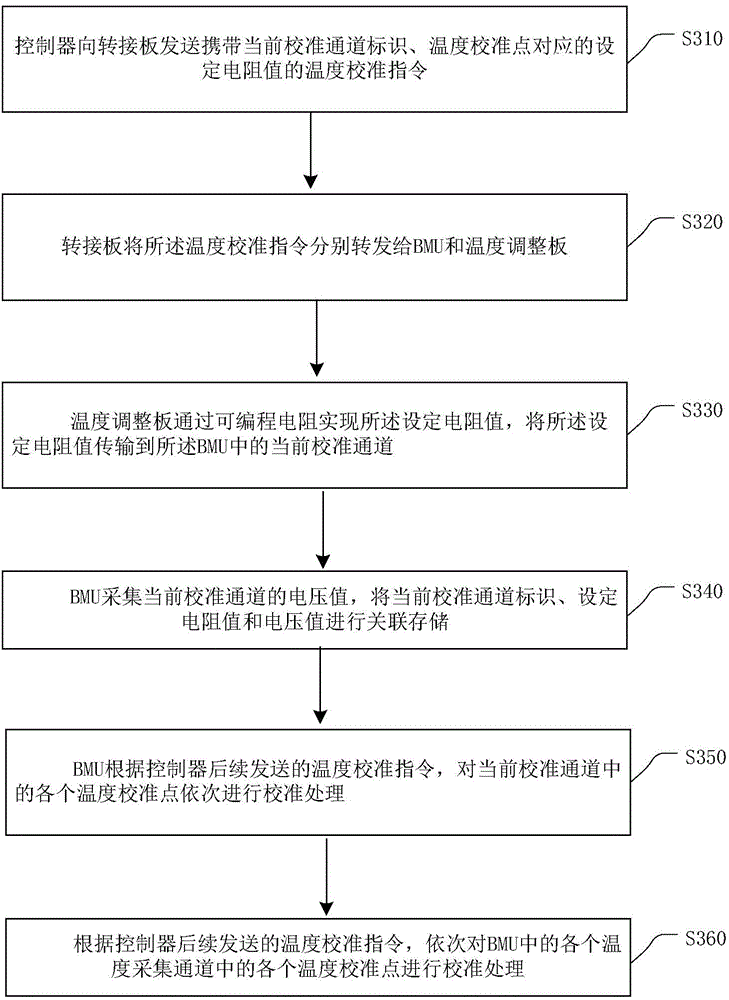

[0067] The purpose of the embodiment of the present invention is to design an automatic calibration method to realize the automatic calibration of the BMU temperature acquisition channel. This embodiment provides a schematic diagram of the implementation principle of a method for calibrating the temperature acquisition channel in the battery management system. figure 2 As shown, the implementation system of this method is composed of a controller, an adapter board, a temperature adjustment board and a BMU. The controller is used to control the calibration process, and the adapter board is used for data communication between the controller, the temperature adjustment board and the BMU. The adjustment board receives the command sent by the controller to control the programmable resistor network, and the BMU receives the current analog resistance value sent by the controller, and collects and records the collected voltage value.

[0068] This embodiment provides a processing flo...

Embodiment 2

[0094] This embodiment provides a device for calibrating the temperature acquisition channel in the battery management system, and its specific implementation structure is as follows Figure 5 As shown, specifically, the following modules may be included: a controller 51 , an adapter board 52 , a temperature adjustment board 53 and a battery management system 54 .

[0095] The controller 51 is configured to send a temperature calibration instruction carrying the current calibration channel identifier and the set resistance value corresponding to the temperature calibration point to the adapter board;

[0096] The adapter board 52 is used to forward the temperature calibration instruction to the battery management system and the temperature adjustment board respectively;

[0097] The temperature adjustment board 53 is used to realize the set resistance value through a programmable resistor, and transmit the set resistance value to the current calibration channel in the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com