Synchronous position randomly adjustable image type calibrating device for four-wheel aligner

A four-wheel aligner and synchronous position technology, applied in wheel testing and other directions, can solve the problems of complex equipment structure, low precision, large volume and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

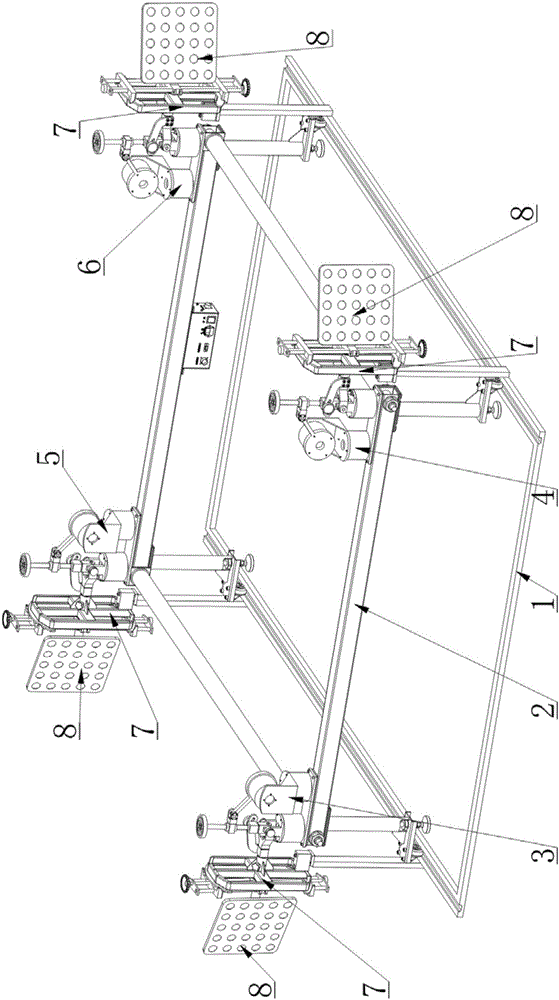

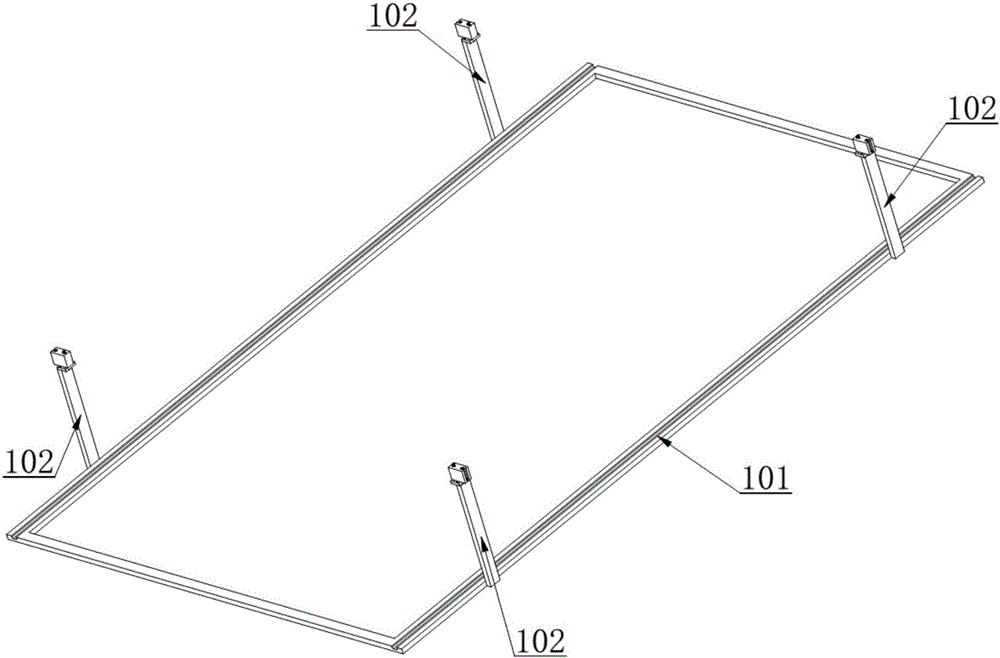

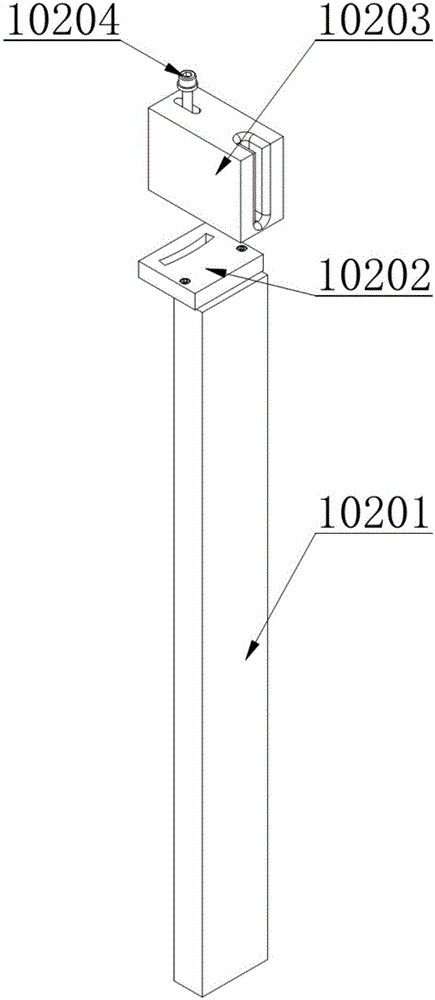

[0064] refer to Figure 1-10, including synchronous mechanism drag frame 1, toe-in zero point inspection frame 2, front left table inspection part 3, front right table inspection part 4, rear left table inspection part 5, rear right table inspection part 6, simulated hub 7, four Wheel clamp assembly 8; the four ground casters 20601 of the toe-in zero-point inspection frame 2 are respectively in contact with and tangent to the left groove of the ground rectangular frame 101 of the synchronous mechanism drag frame 1, and the synchronous slide of the synchronous mechanism drag frame 1 The U-shaped groove of the block 10203 is in contact with and tangent to the drag pin 704 of the simulated hub of the simulated hub 7, and the front left platform inspection part 3 and the front right platform inspection part 4 are respectively installed on the front beam 201 in the toe-in zero-point inspection frame 2 The left end and the right end of the toe-in are fixedly connected with positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com