Follow-up steering mechanism and independent suspension support bridge using same

A follow-up steering and independent suspension technology, applied in the field of vehicles, can solve the problems of the uncertainty of the vehicle's reversing direction, the follow-up steering can not be freely controlled, and the vehicle is not easy to control, so as to reduce abnormal wear and avoid wheels. the effect of oscillating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

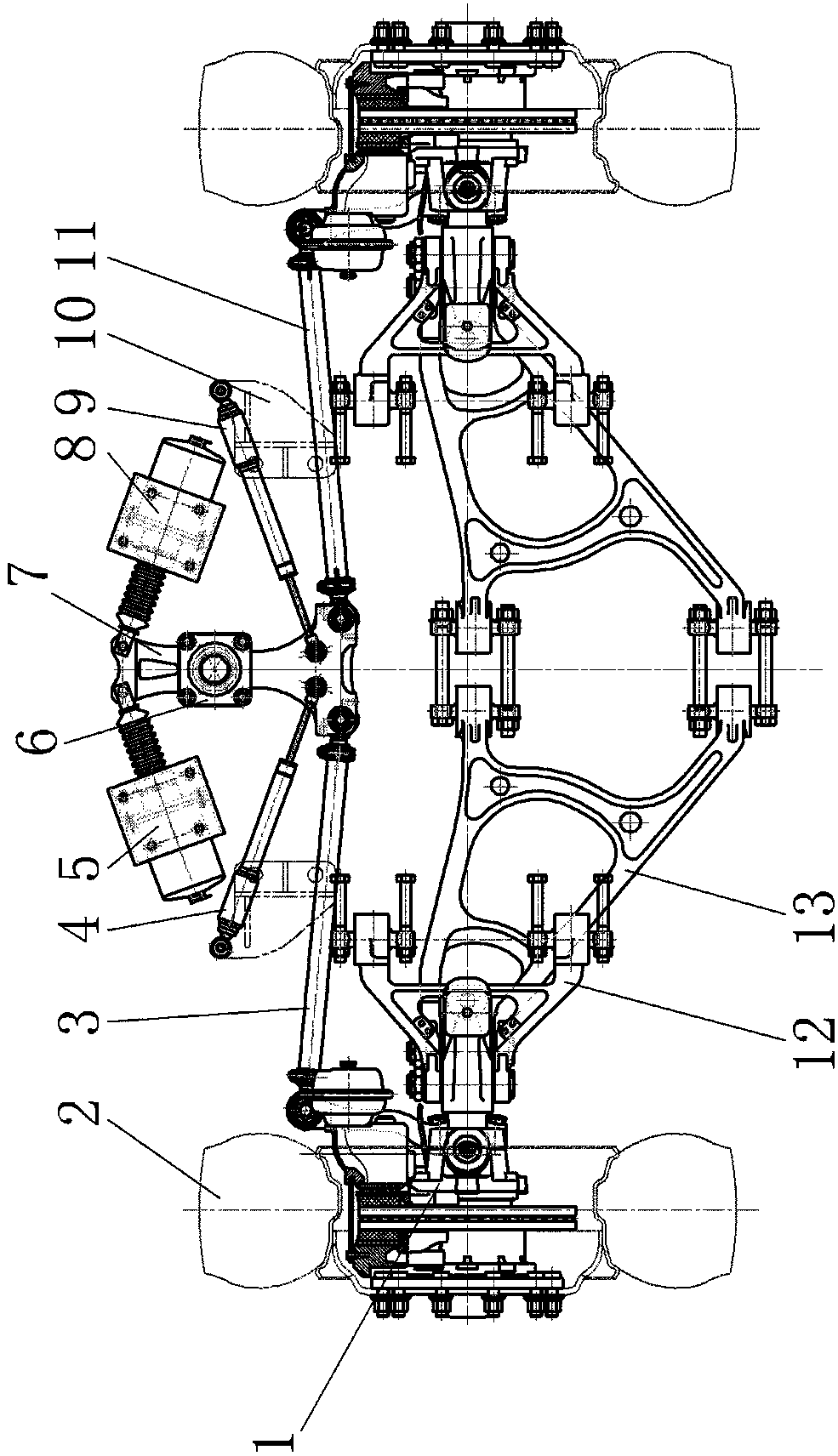

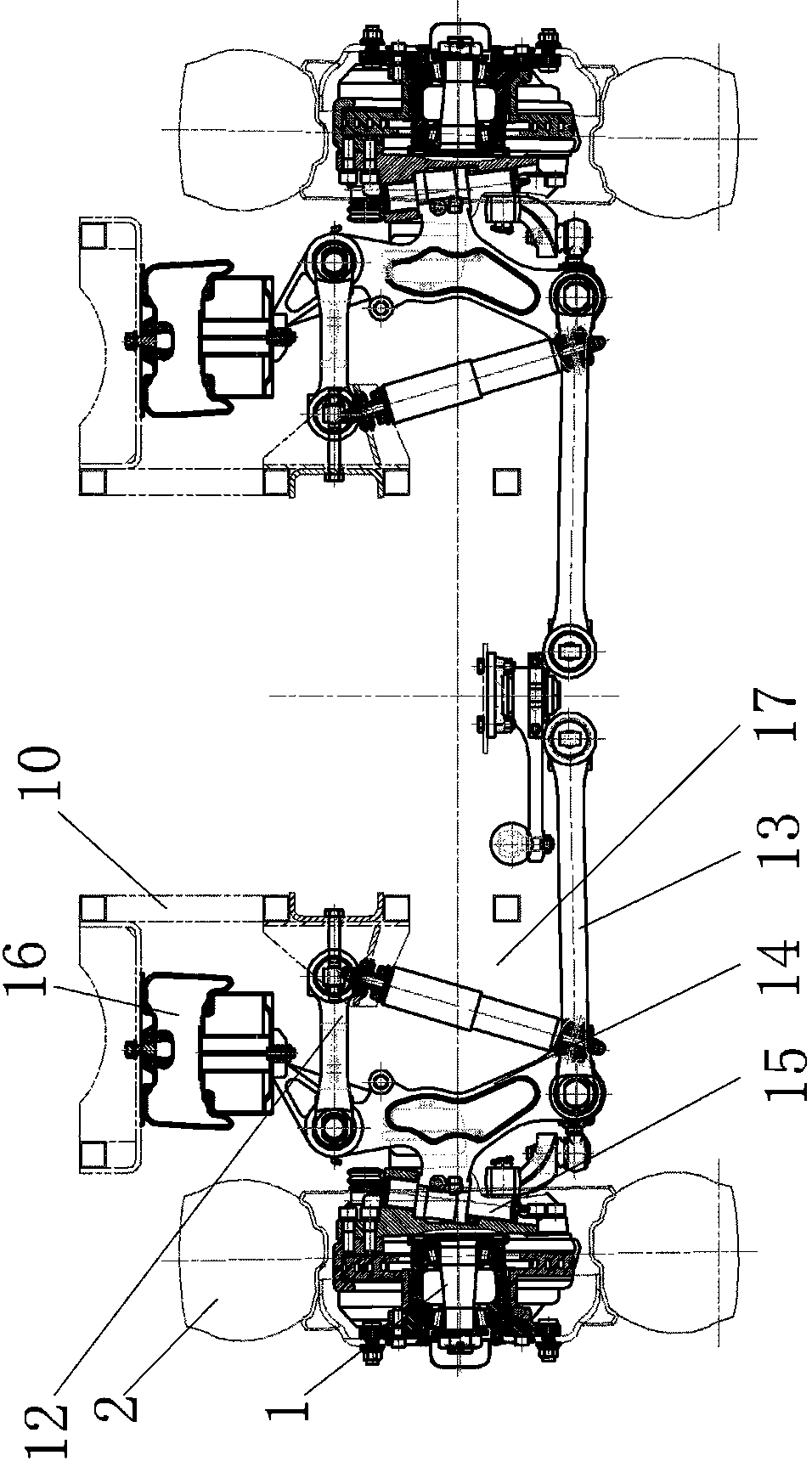

[0019] Examples of follow-up steering mechanisms figure 2 As shown: it includes a steering rocker 7 that can swing left and right and is hinged on the corresponding chassis frame 10. The left and right sides of one end of the steering rocker are respectively hinged with a left end that is used to be hinged with the corresponding steering knuckle assembly 1. The steering rod 3 and the right end are used for the right steering rod 11 that is hingedly connected with the corresponding right steering knuckle assembly. The middle part of the steering rocker arm 7 is provided with a hinged section 6 for realizing its hinged connection with the corresponding chassis frame 10. The steering rocker arm 7 A loading mechanism that applies a loading force to the steering rocker arm 7 so that the steering rocker arm 7 is locked and thus makes the corresponding wheels walk in a straight line is provided between one end away from the left and right steering tie rods and the corresponding chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com