Calibrating device for SF6 density relay checking instrument

A technology of density relays and verification devices, which is applied in the direction of measuring devices, instruments, and measuring electrical variables, etc., can solve problems such as unfavorable industry standards and unfavorable industry monitoring, and achieve the effect of improving precision and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described by taking the structure of the verification device of the specific SF6 density relay calibrator as an embodiment.

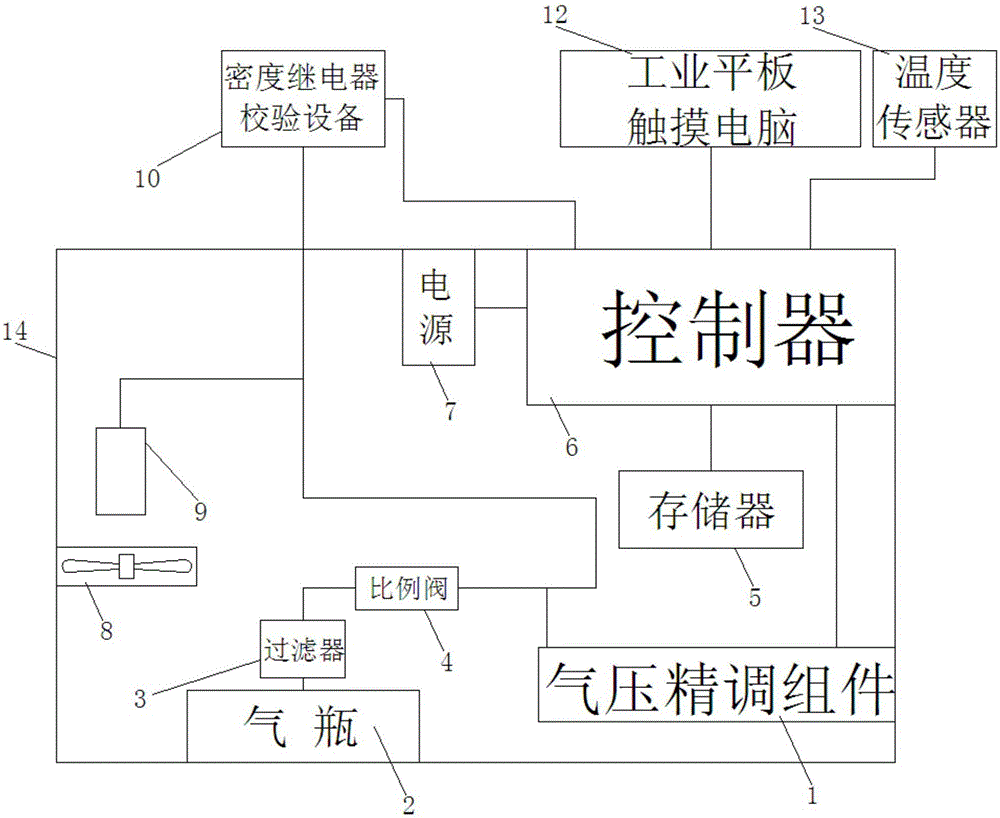

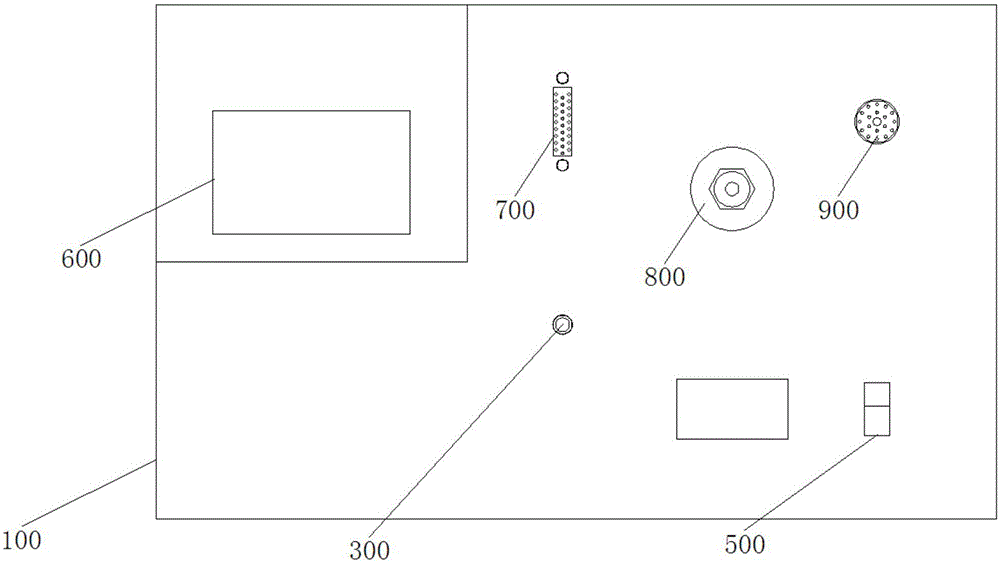

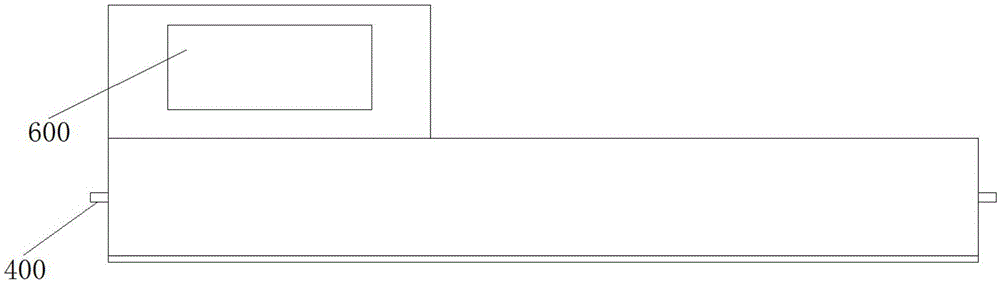

[0044] Such as Figure 1~5 As shown, the SF6 density relay calibrator verification device includes a controller 6, the controller is connected to an industrial tablet touch computer 12, a temperature sensor 13 and a density relay verification device 10 to be verified;

[0045] As shown in the figure, the density relay verification device 10 is a device for verifying SF6 density relays; the density relay verification device includes an air filling port 210 and a signal line interface 207; the controller 6 and the waiting The signal line interface 207 of the verified density relay verification device 10 is connected;

[0046] As shown in the figure, it also includes an inflation pipeline connected with the inflation port of the density relay calibration equipment to be verified; the gas cylinder 2 and the proportional valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com