Calibration device and method for gas mass flow meter in special working state

A technology of gas mass flow and working status, which is applied in the direction of testing/calibration devices, measuring devices, liquid/fluid solid measurement, etc., and can solve problems such as inability to adapt to calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

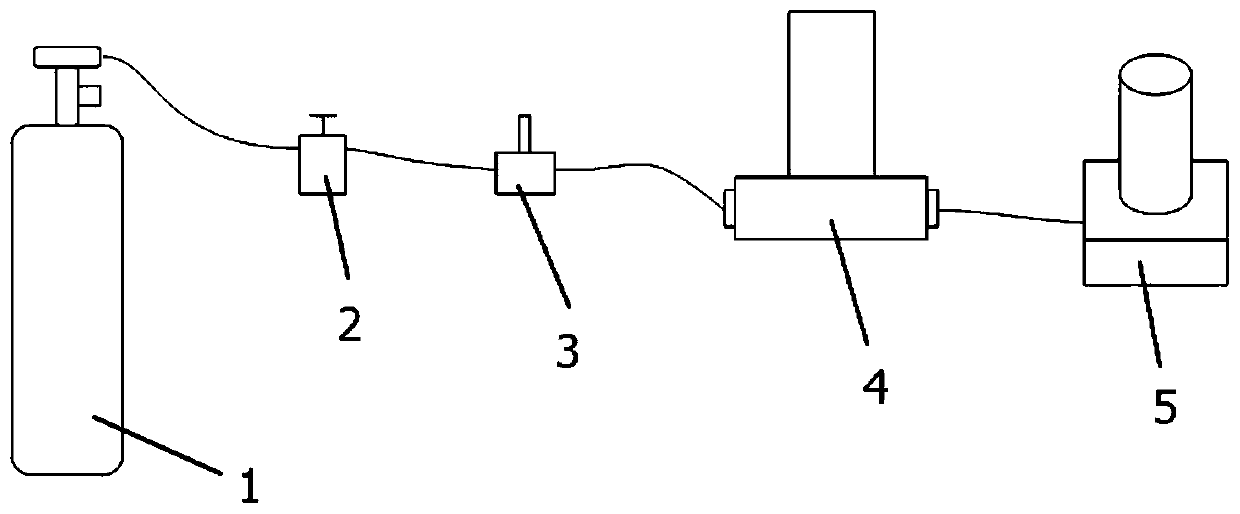

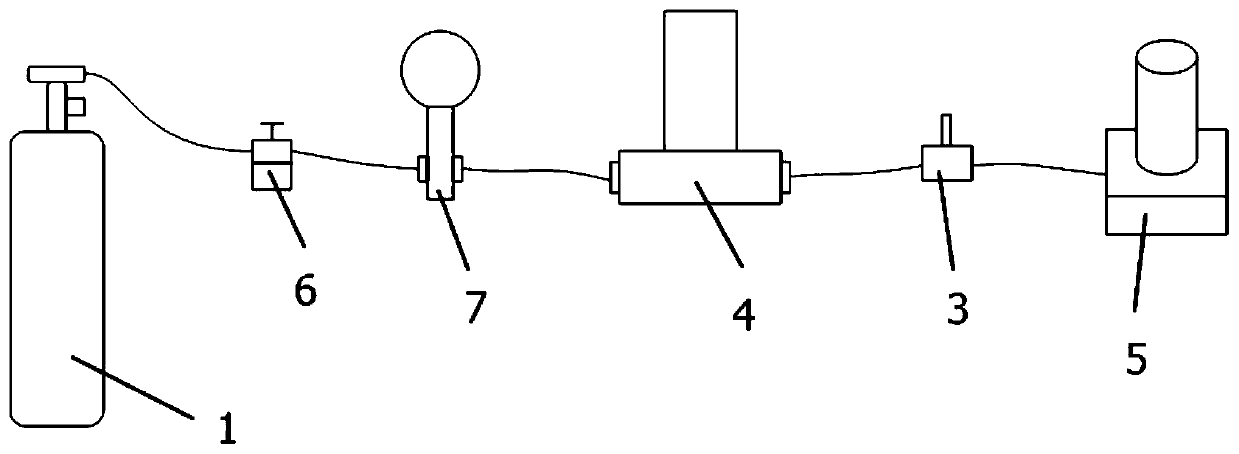

[0028] Existing thermal gas mass flowmeter calibration devices such as figure 1 As shown, the calibration system mainly includes a gas generator 1 with high-purity nitrogen as the gas source, a pressure stabilizing valve 2, a flow regulating valve 3, a flow meter to be tested 4, and a standard device 5, etc. These devices are connected in series in sequence. A pressure stabilizing valve and a flow regulating valve are added to the front end of the thermal gas mass flowmeter, and its inlet pressure is basically normal pressure. In industrial sites, there are many types of gas media actually used, and some are even mixed gases. Thermal gas mass flowmeters may also work under high pressure. For example, iron and steel companies often use argon or argon and carbon dioxide mixed gases. As a gas medium, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com