Flame arrester

A flame remover and flame technology, applied in the direction of burners, fire rescue, gas fuel burners, etc., can solve the problems that it is difficult to meet the required manufacturing accuracy, increase the pressure loss of combustible gas, etc., and achieve easy disassembly and reinstallation, friction Less pressure loss, elimination of deflagration and explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

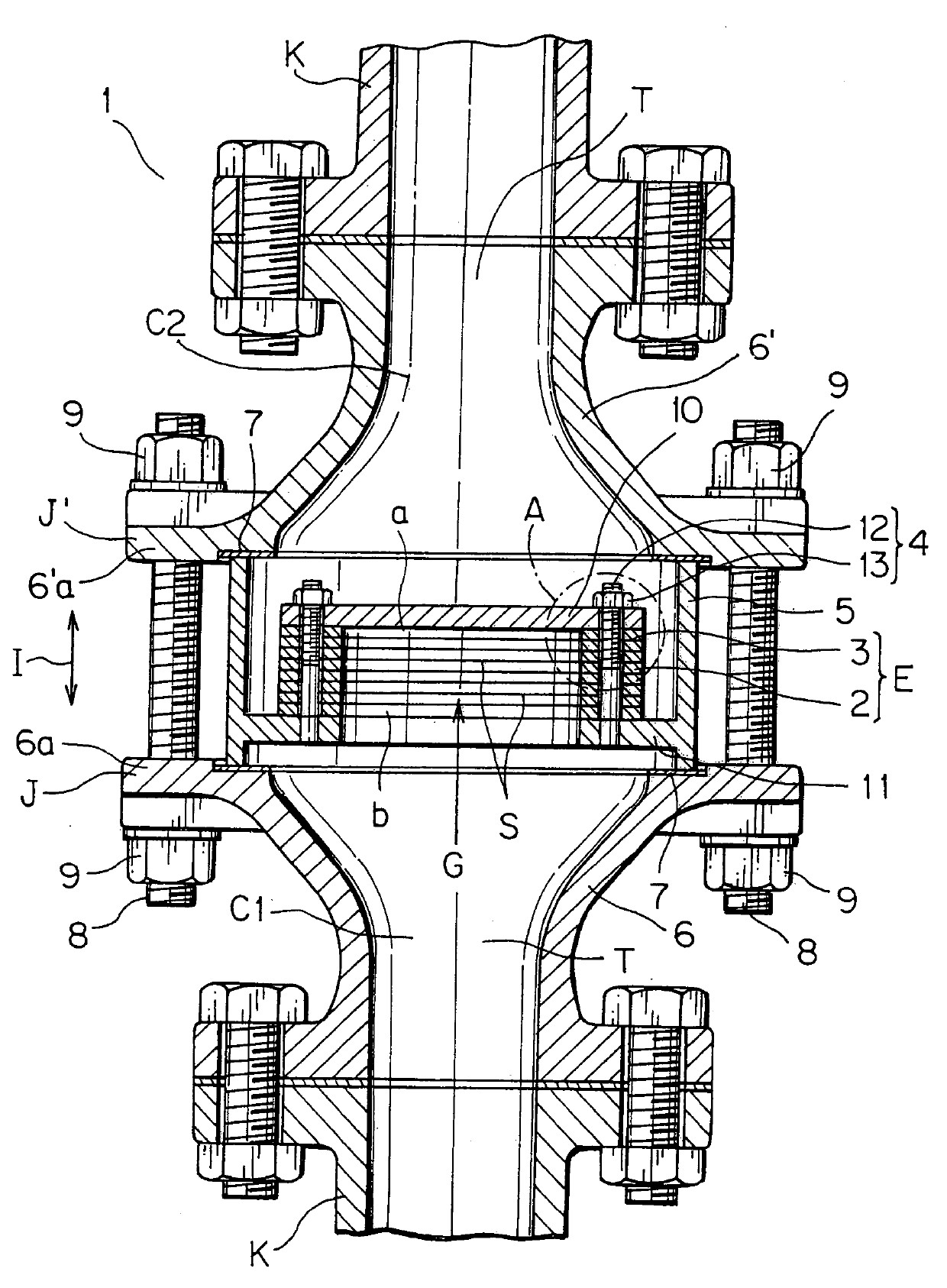

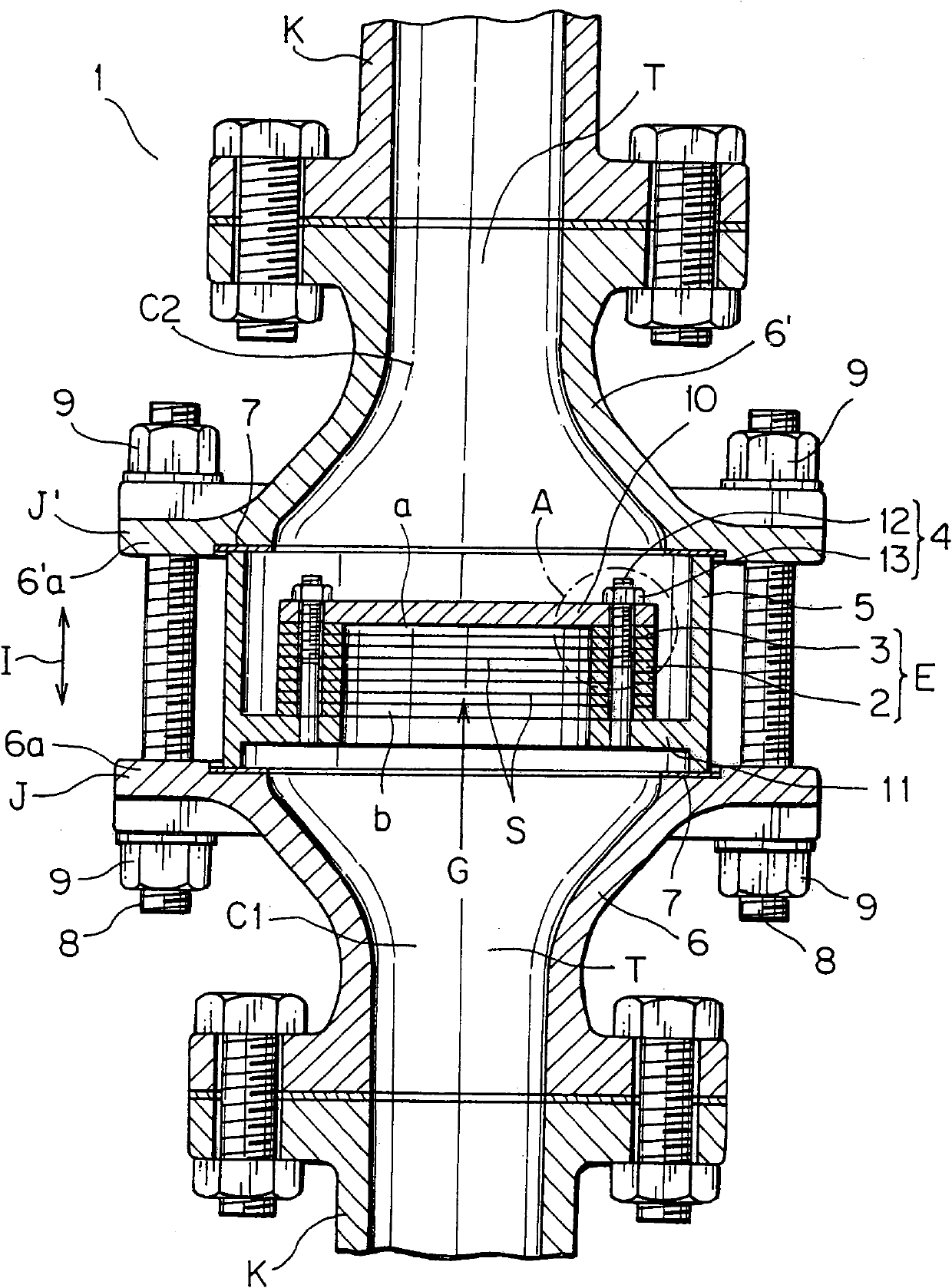

[0016] A preferred embodiment for carrying out the present invention is described in detail herein with reference to the accompanying drawings.

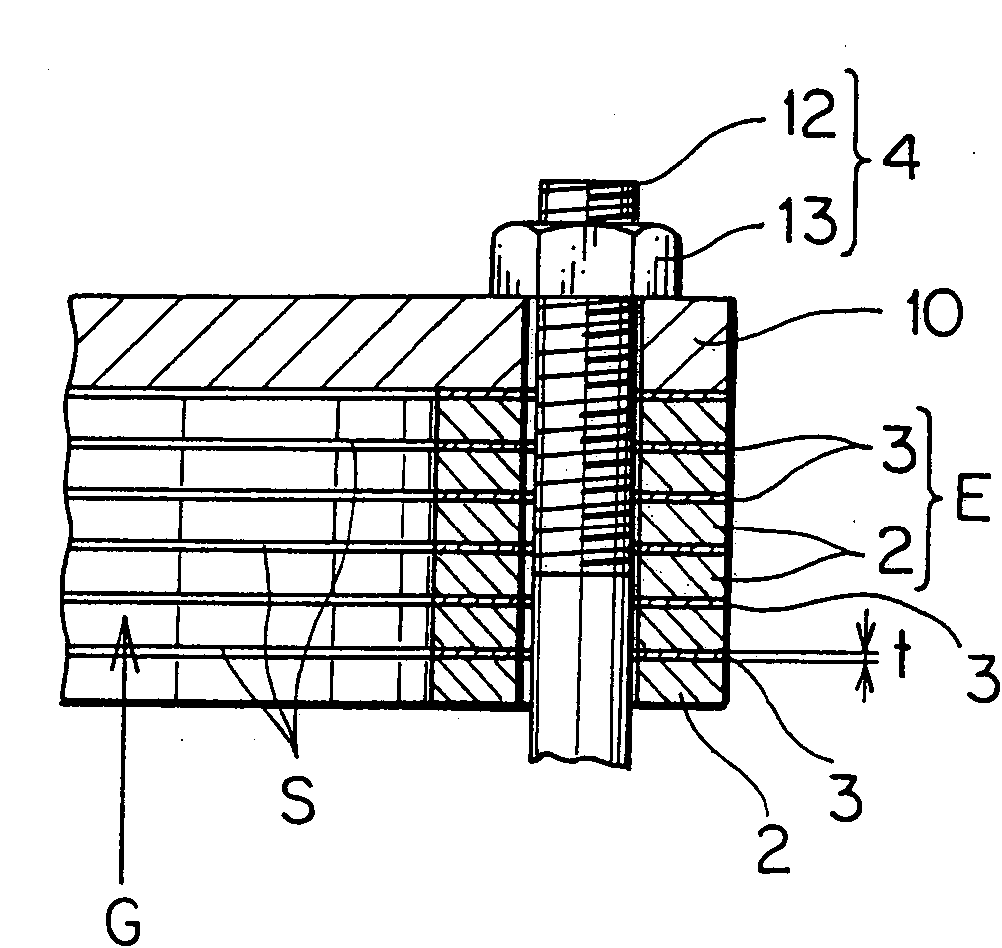

[0017] figure 1 and figure 2 Embodiment 1 of the flame arrester according to the present invention is shown. The flame arrester of this embodiment is installed in the pipe K through which the combustible gas G flows, so as to prevent the reverse flow from the downstream side C2 to the upstream side C1 of the flame generator. The flame arrester is characterized by having a drum-shaped body E comprising a plurality of annular plates 2 . The annular plates are stacked with a plurality of spacers 3 therebetween, defining slits S between the annular plates. The drum-shaped body has a first end b open to the upstream side C1 and a second end closed to the downstream side, while the slit is open to the downstream side.

[0018] The flame arrester 1 of this embodiment 1 is installed in the flow channel, such as the open end or the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com