Tooling clamp for spanner slab

A tooling fixture and wrench technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of low machining accuracy and easy movement of wrench blanks, and achieve the effect of ensuring machining accuracy and avoiding movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

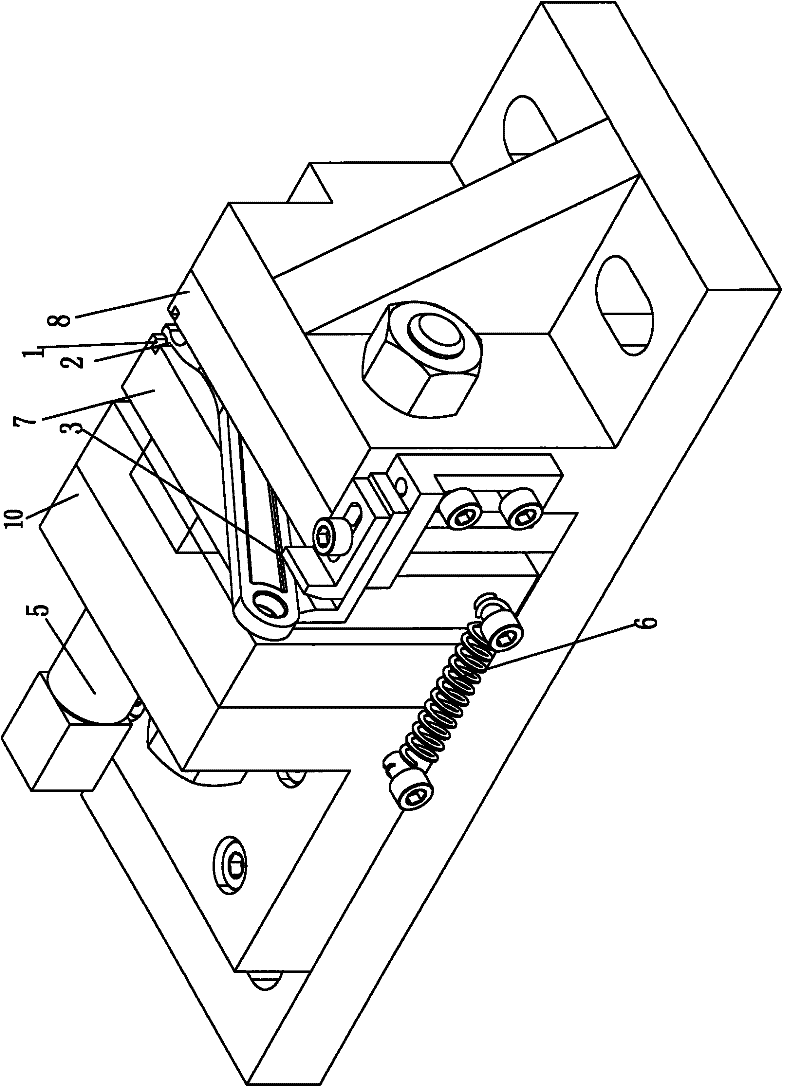

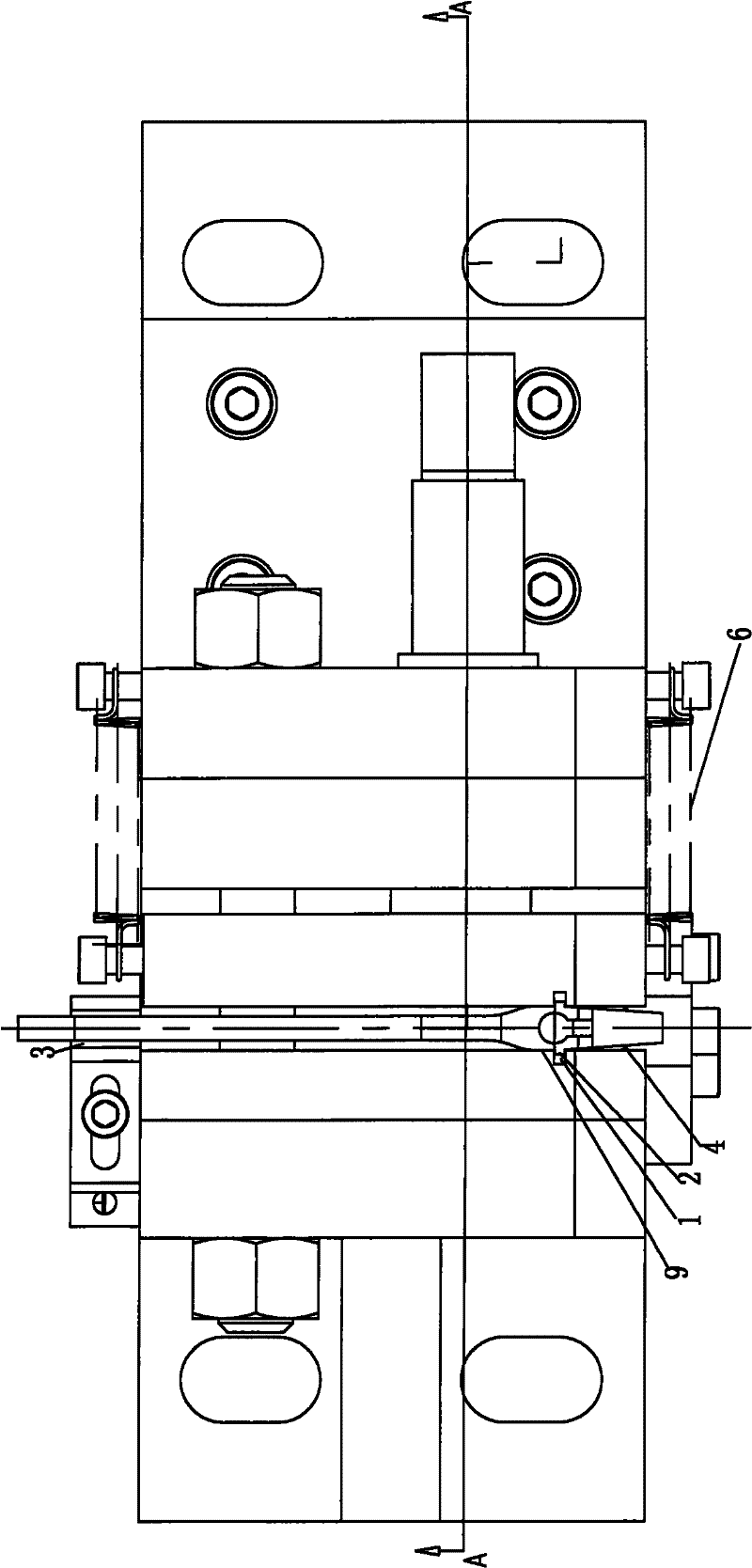

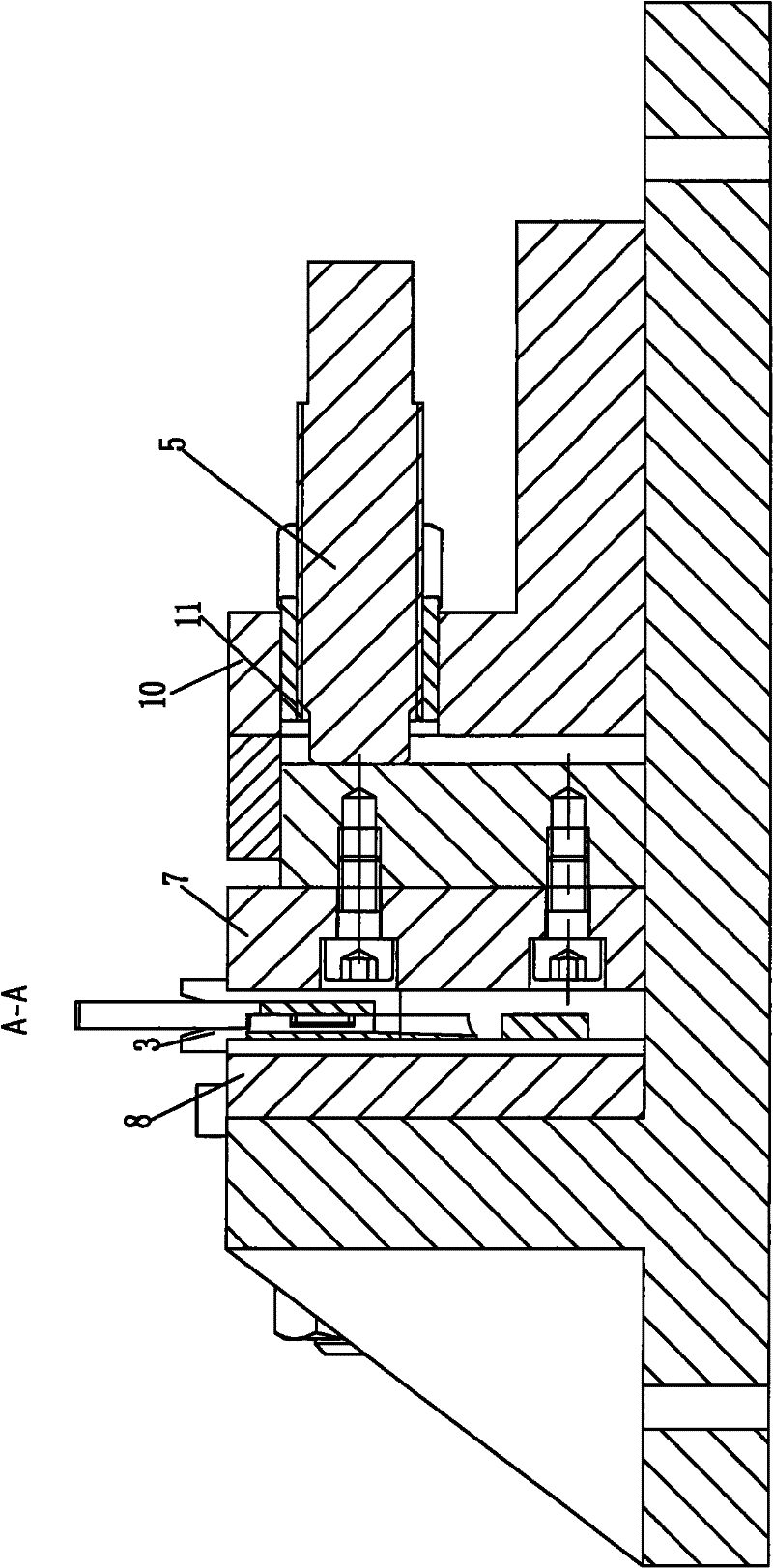

[0013] see figure 1 As shown, a tooling fixture of a wrench blank is shown in the form of a perspective view. The tooling fixture has a fixed splint 8 and a movable splint 7 that can move left and right relative to the fixed splint 8. The fixed splint 8 and the movable splint 7. There are respectively vertically arranged grooves 1 on the opposite surfaces that match the convex strips 2 extending along the transverse direction of the wrench blank head. The opposite surface is inclined and set away from the bottom to the top, so that when the fixed wrench blank is installed, the convex strips 2 on the left and right sides of the wrench blank are placed in the groove 1 of the fixed splint 8 and the movable splint 7, and the tail of the wrench blank Then it is clamped between the opposite inclined surfaces on the tail bracket 3. This method helps to realize the precise po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com