Film paraptera bending device

A bending device and film technology, applied in metal processing, flat products, household appliances, etc., can solve the problems of rising film production costs, low production efficiency, and high incidence of defects, so as to improve film production efficiency, reduce production costs, reduce human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the thin film fin bending device according to the present invention will be described in detail with reference to the drawings.

[0029] figure 1 , figure 2 It is a preferred embodiment of the film fin bending device 10 according to the present invention. As shown in the figure, the structure according to the present invention is as follows.

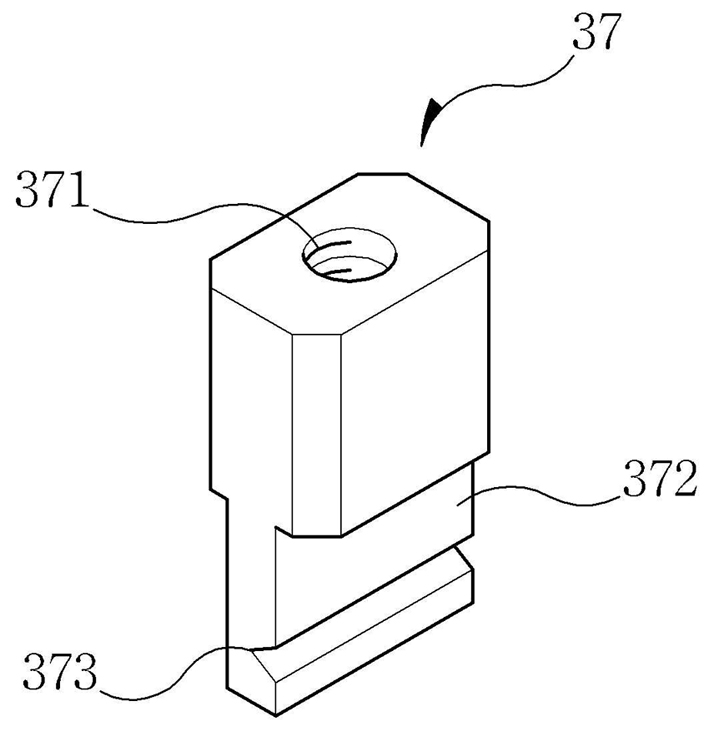

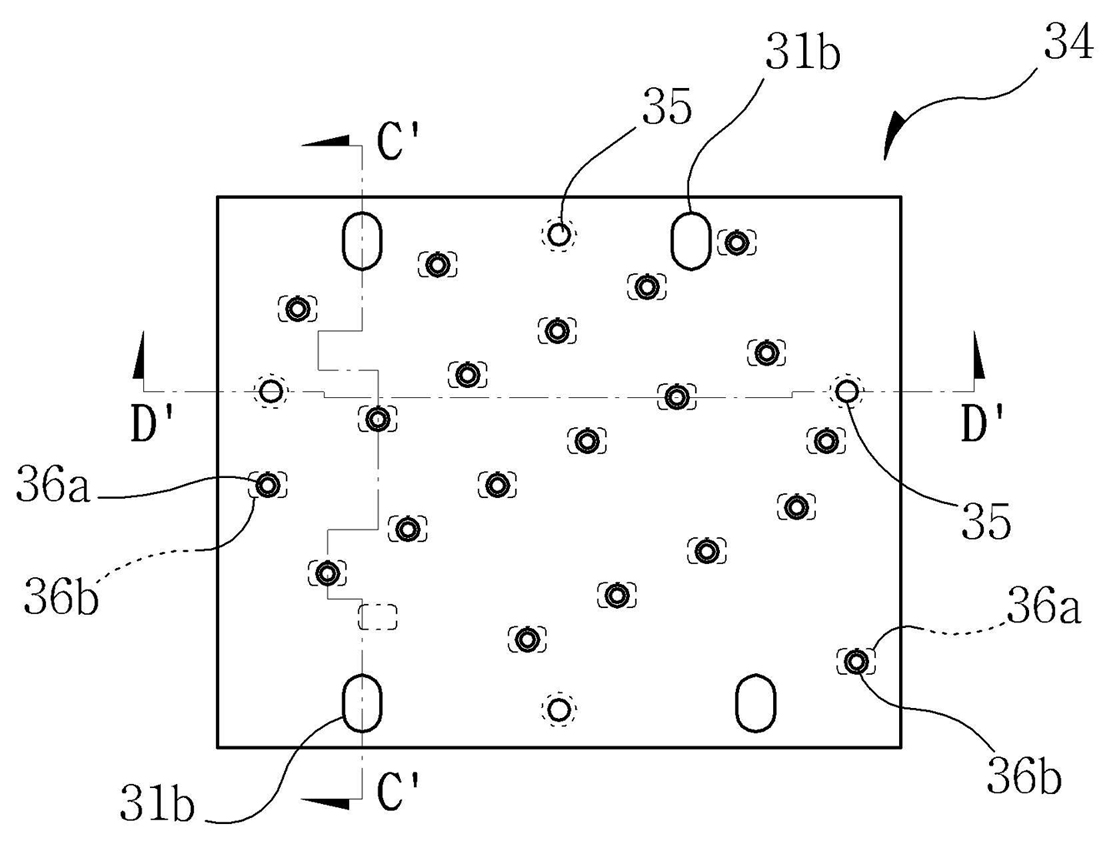

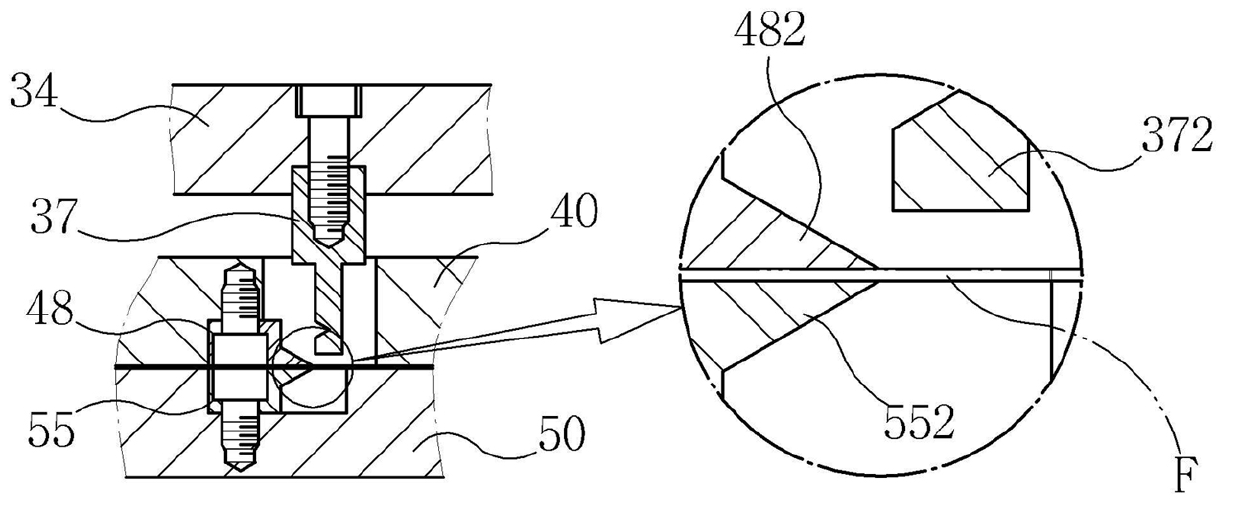

[0030] On the upper end portion and the central part of the frame 11, a lifting platform 12 and a bending platform 13 which maintain a certain interval are respectively arranged, and between the lifting platform 12 and the bending platform 13, a plurality of lifting rods L1 are arranged in the horizontal direction; on the lifting platform 12 The lifting cylinder C1 is set on the top of the lifting rod L1 combined with the lifting plate 20, the lifting plate 20 can be lifted up and down by the lifting cylinder C1; the sliding plate 30 that can slide is set on the lifting plate, and the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com