Laser write-through organic thermal etching material and preparation method thereof

A technology of laser direct writing and thermal etching, which is applied in the preparation of organic compounds, photosensitive materials for optomechanical equipment, organic chemistry, etc., can solve the problems of low efficiency, complicated process, and restrictions on wide application, and achieve cost reduction , Simplify the structure of the film layer and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method steps of the present embodiment are as follows:

[0029] Weigh the synthetic raw materials in the following percentages by weight:

[0030] 1,2,3-triphenol: 8.4wt%; concentrated hydrochloric acid: 16.8wt%; 4-hydroxybenzaldehyde: 8.1wt%; ethanol: 66.7wt%.

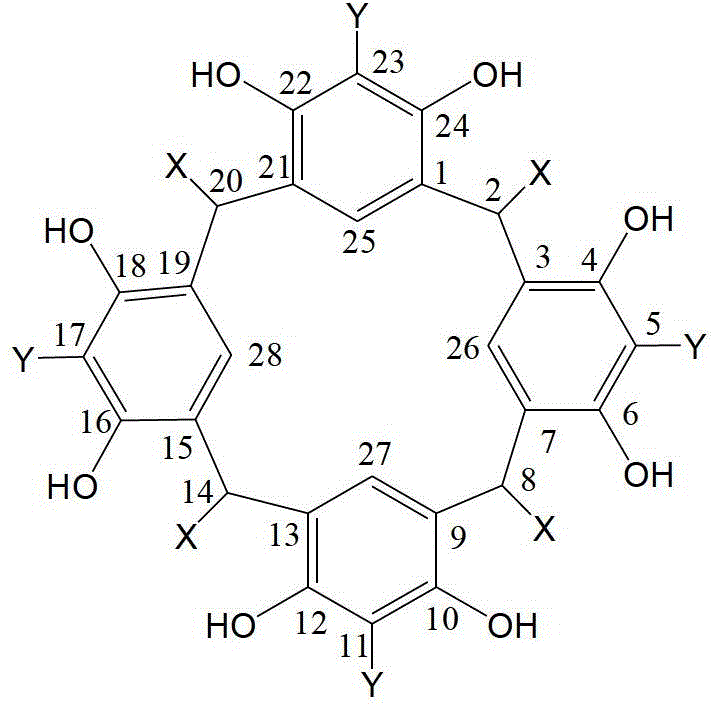

[0031] Dissolve 1,2,3-triphenol in ethanol solution, pass it under the protection of nitrogen, stir and slowly add concentrated hydrochloric acid dropwise, and then slowly add 4-hydroxybenzaldehyde dropwise, at 78 Stirring reaction at ℃ for 12 hours, the reaction formula is as above;

[0032] After the reaction, let stand and cool for 2 hours, the product precipitated from the reaction solution, filtered off the obtained product, and dried in vacuum at 50°C to obtain 2, 8, 14, 20-tetra-4-hydroxybenzene-4, 6, 10 , 12, 16, 18, 22, 24, 25, 26, 27, 28-dodecahydroxycalix[4]arene.

[0033] Electron bombardment mass spectrometry test: theoretical molecular weight C 52 h 40 o 16 :920.23, mass s...

Embodiment 2

[0035] The preparation method steps of the present embodiment are as follows:

[0036] Weigh the synthetic raw materials in the following percentages by weight:

[0037] 1,2,3-triphenol: 5.6wt%; concentrated hydrochloric acid: 22.3wt%; n-heptanal: 5.1wt%; ethanol: 44.7wt%; deionized water: 22.3wt%. .

[0038] Dissolve 1,2,3-triphenol in a solution of ethanol and deionized water, pass it under the protection of nitrogen, stir and slowly add concentrated hydrochloric acid dropwise, and then slowly add n-heptanal dropwise , stirring and reacting at 78°C for 22 hours, the reaction formula is as above;

[0039] After the reaction, let stand and cool for 2 hours, the product is precipitated from the reaction solution, and the obtained product is filtered out, and vacuum-dried at 65°C to obtain 2, 8, 14, 20-tetra-n-hexyl-4, 6, 10, 12 , 16, 18, 22, 24, 25, 26, 27, 28-dodecahydroxycalix[4]arene.

[0040] Electron bombardment mass spectrometry test: theoretical molecular weight C...

Embodiment 3

[0042] The preparation method steps of the present embodiment are as follows:

[0043] Weigh the synthetic raw materials in the following percentages by weight:

[0044] 1,2,3-triphenol: 5.6wt%; concentrated hydrochloric acid: 22.5wt%; 3-cyclohexene-1-carbaldehyde: 4.9wt%; ethanol: 33.5wt%; deionized water: 33.5wt%. .

[0045] Dissolve 1,2,3-triphenol in a solution of ethanol and deionized water, pass it under the protection of nitrogen, stir and slowly add concentrated hydrochloric acid dropwise, and then slowly add 3-cyclohexene-1 - Formaldehyde was added dropwise, stirred and reacted at 78°C for 18 hours, the reaction formula was as above;

[0046] After the reaction was completed, let it stand for cooling for 1 hour, the product was precipitated from the reaction solution, and the obtained product was filtered off, and vacuum-dried at 65°C to obtain 2, 8, 14, 20-tetra-3-cyclohexene-4, 5, 6, 10, 11, 12, 16, 17, 18, 22, 23, 24-Dodecahydroxycalix[4]arene.

[0047] Electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com