Quantitative turnover box loop conveying process for cigarette packaging production line

A packaging production line and turnover box technology, applied in the field of tobacco transportation, can solve the problems affecting the effective operation rate of workshop production, waste of raw materials, dense transportation tracks, etc., to reduce equipment maintenance and management work, reduce investment costs, and fast transportation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

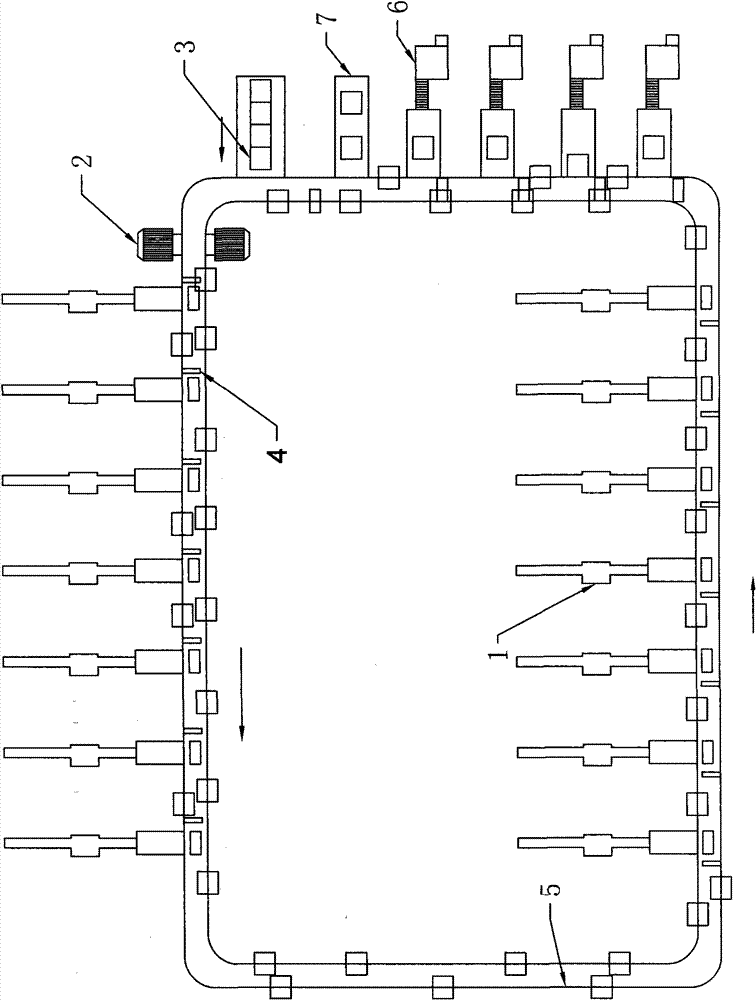

[0027] The present invention will be further described below. The preferred embodiment of the present invention is: the quantitative turnover box loop conveying process for the cigarette packaging production line described in this embodiment is: the finished cigarettes exported from the packaging machine are loaded into the empty turnover box→ The turnover box is lifted→the loop elevated conveyor line transports the turnover box→the box packing and sealing machine designated by the turnover box system goes down→the cigarettes in the turnover box are unloaded into the box packing and sealing machine process→the empty turnover box→lifting→conveyed by the loop elevated conveyor line → Empty turnover boxes are dropped at the exit of any necessary packaging machine to be loaded. At the same time, turnover boxes that need to be returned (including RFID information errors, packaging defects, and quality problems) → Lifting → Loop elevated conveyor line transportation → Turnover boxes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com