System and method for denitrification treatment on stainless steel pickling wastewater

A technology of pickling wastewater and treatment system, which is applied in the field of water treatment, and can solve problems such as complex operation management, maintenance and replacement of aeration pipes, and easy failure of electromechanical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

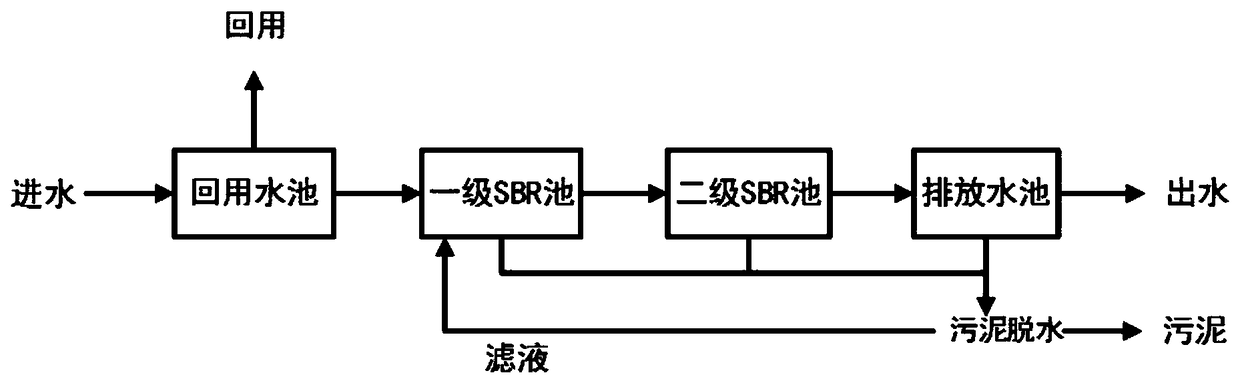

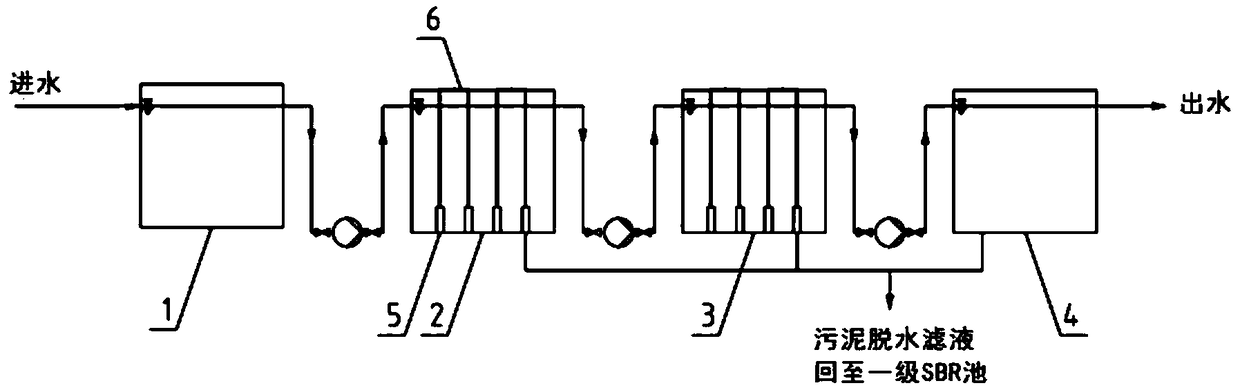

[0042] The water volume and total nitrogen concentration of stainless steel pickling wastewater vary greatly, and in addition to containing a large amount of nitrate nitrogen, there is also ammonia nitrogen that is catalyzed after reuse of reclaimed water. After secondary neutralization and precipitation of stainless steel pickling wastewater discharged by a stainless steel production enterprise, 80% of the water is reused, and 20% of the water enters the subsequent stainless steel pickling wastewater denitrification treatment system, see Figure 1-2 , the system includes sequentially connected reuse pool 1, primary SBR pool 2 (divided into two compartments: A and B pools), secondary SBR pool 3 (divided into two compartments: A and B pools), discharge pool 4, Several aerators 5 are arranged in the SBR pool, and the aerator is installed at the bottom of the SBR pool, and the aerator is connected with an air inlet pipe 6, and the air inlet pipe 6 is installed on the top of the SB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com