A non-power-limited flow-limiting intelligent interception well with a clapboard slag-retaining device

A technology of interception wells and baffles, applied in the field of interception wells, can provide a direct basis for the design, operation and management of wells and pipelines that cannot be intercepted, the baffles cannot completely intercept floating objects and solid substances, and cannot achieve accurate flow restriction. The interception multiple and other issues can achieve high-efficiency solid interception effect, eliminate daily monitoring tasks, and achieve the effect of quantitative control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

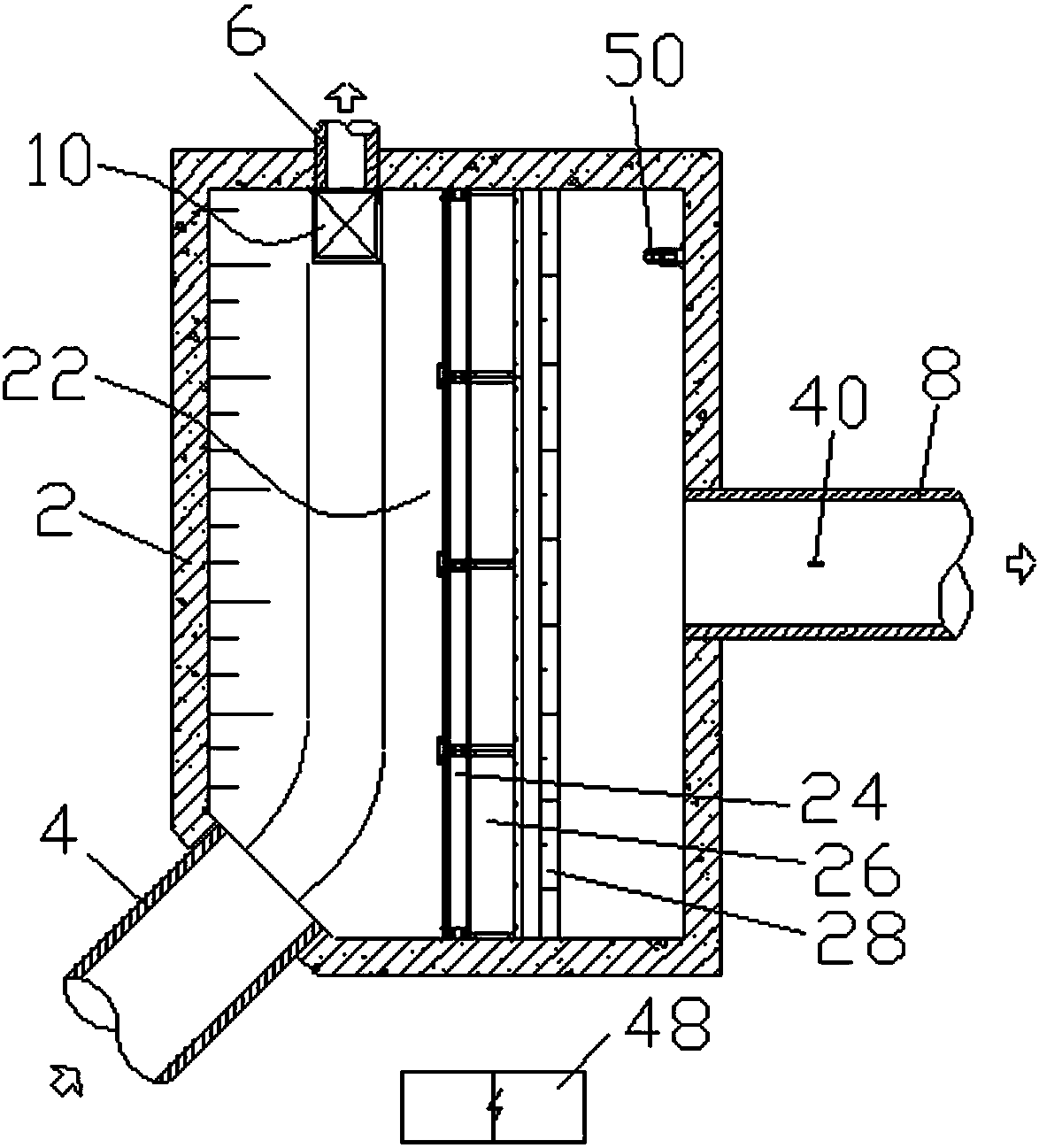

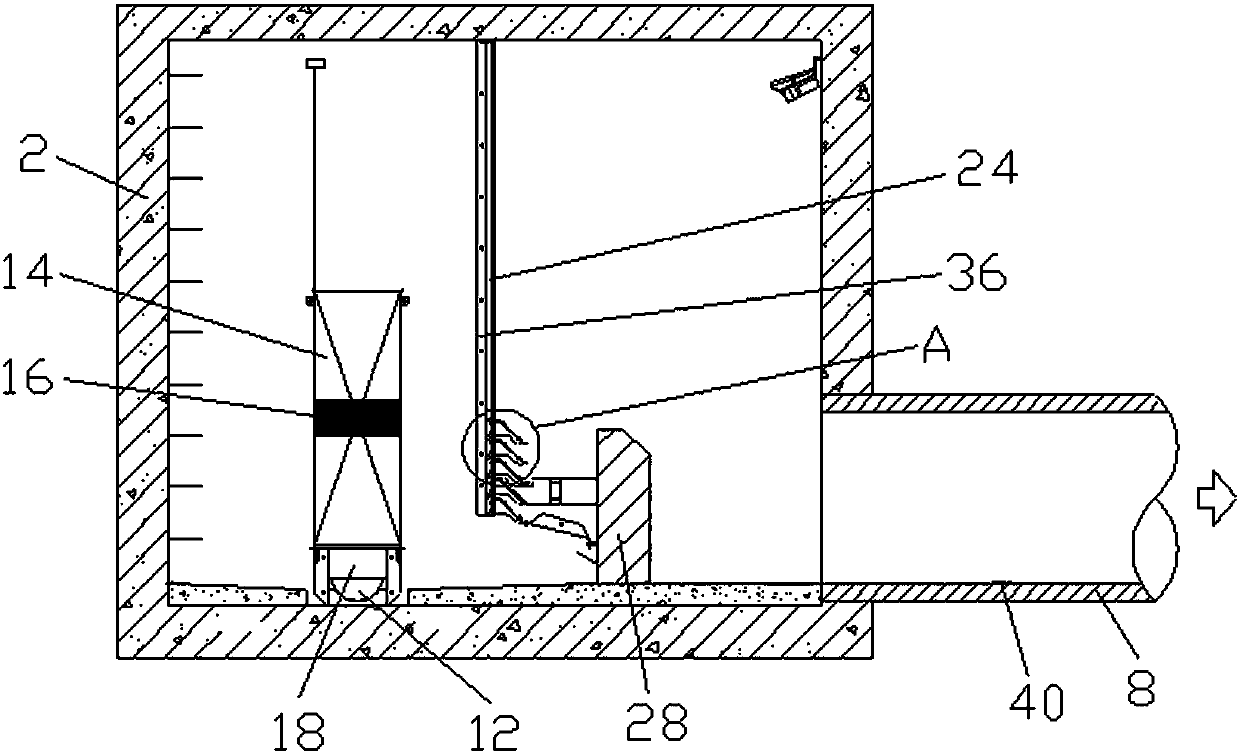

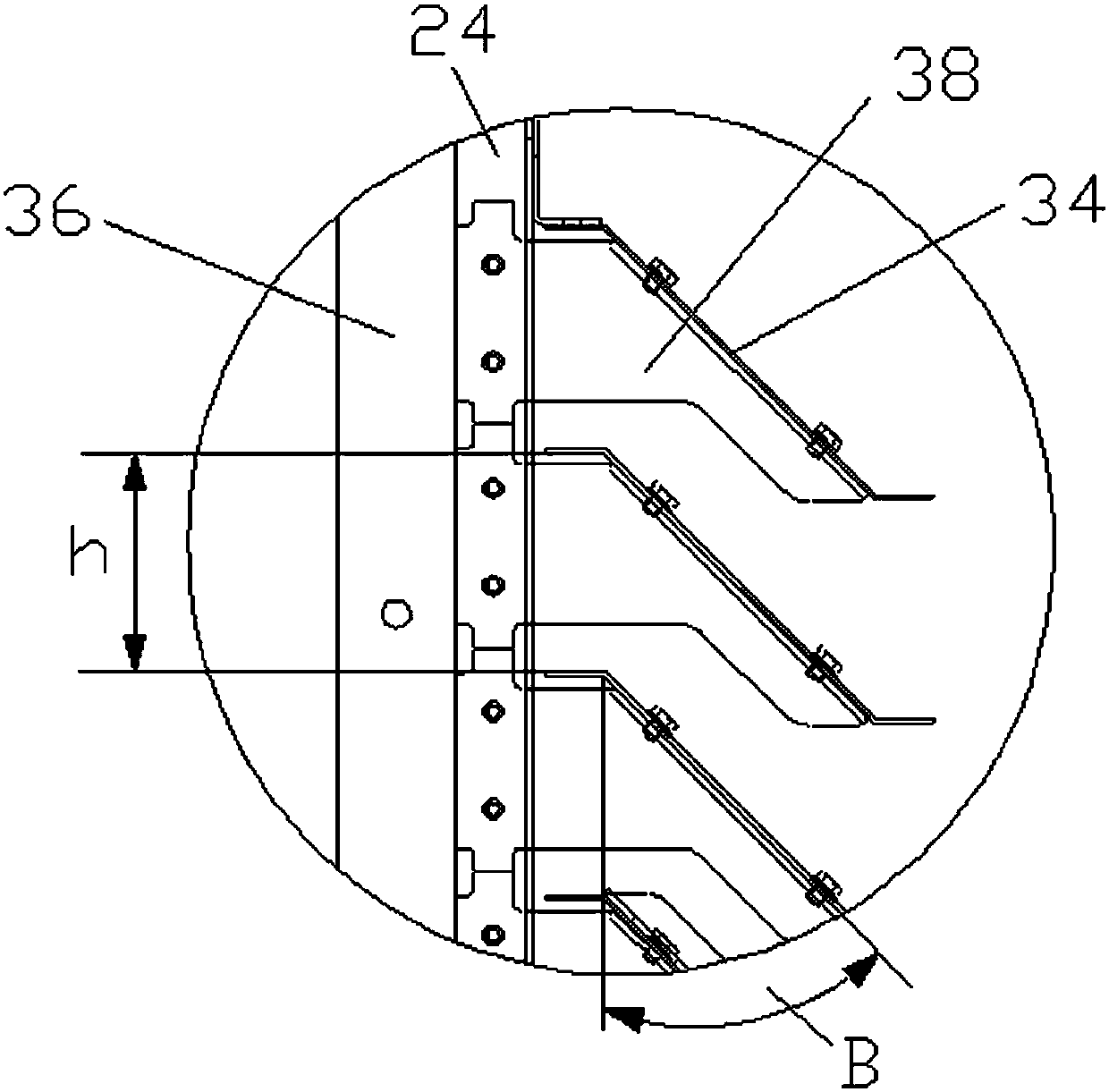

[0031] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0032] Such as Figure 1-Figure 3 As shown, a non-powered flow-limiting smart interception well with a partition slag blocking device includes a well body 2, and the side walls of the well body 2 are respectively connected with a sewage inlet pipe 4, an interception sewage pipe 6 and an overflow outlet pipe. 8. A flow limiter 10 is installed in front of the shut-off sewage pipe 6. The flow limiter 10 includes an orifice 12, a chamber 14, a floating ball 16 and a gate 18 in the chamber 14, and the orifice 12 is connected to the shut-off sewage pipe 6 There is a linkage mechanism 20 connected between the floating ball 16 and the flashboard 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com