Nickel complex and preparation and application thereof

A technology of metal complexes and nickel salts, applied in the field of nickel metal complexes and their preparation and application

Inactive Publication Date: 2011-01-19

金永利 +2

View PDF10 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Formula I

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

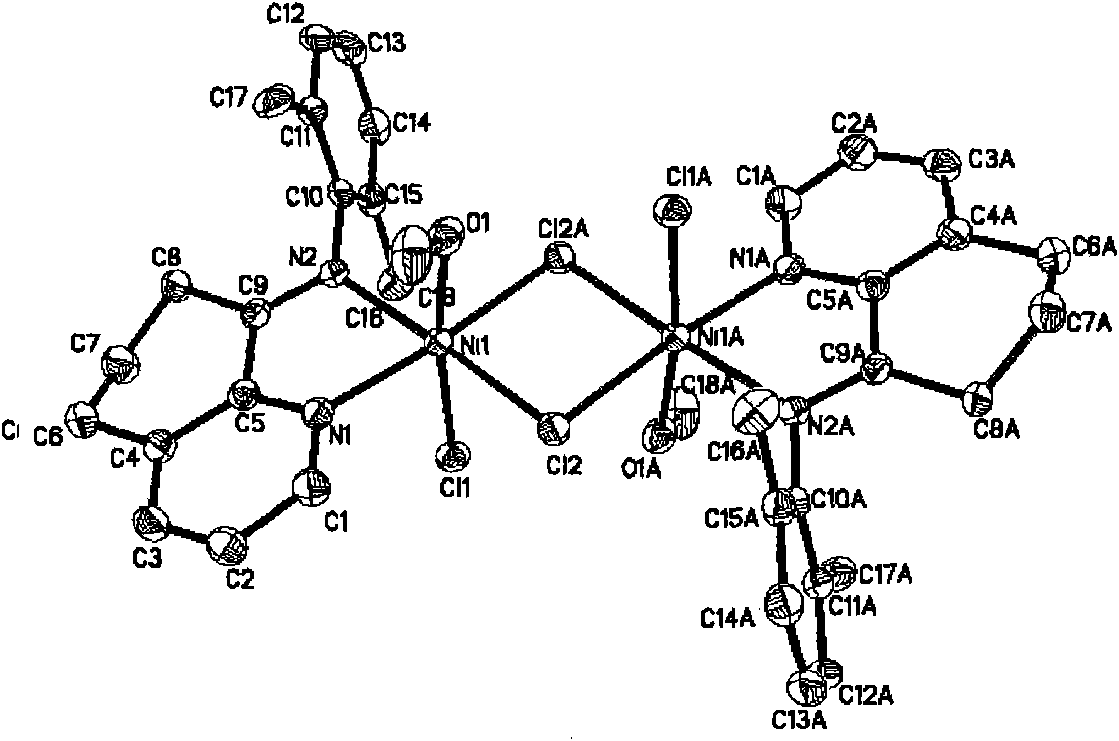

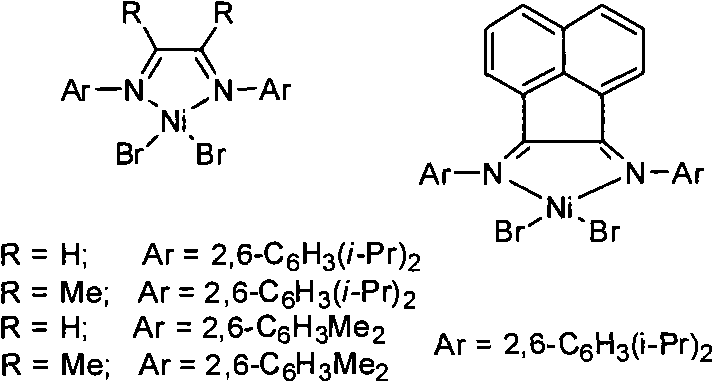

The invention discloses a nickel complex. The structure of the nickel complex is shown in the formula I, wherein R1 is C1-C3 alkyl; R2 is hydrogen, methyl or ethyl; R3 is hydrogen, halogen or aromatic base; and X is halogen. The invention also provides a preparation method and application of the nickel complex. The nickel complex has better catalytic property in the ethylene oligomerization and polymerization reactions in the presence of a cocatalyst aluminoxane or alkylaluminum. The polymerization activity of the complex reaches 1.24*10<7>g.mol<-1> (Ni).h<-1>, at the same time, the molecular weight distribution can be lowered to 1.8 and the oligomerization activity of the complex can reach 9.5*10<6>g.mol<-1> (Ni).h<-1>. The formula I is shown in the specification.

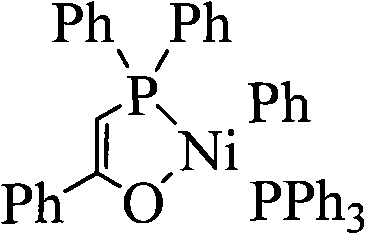

Description

technical field The invention relates to a nickel metal complex and its preparation and application. Background technique The rapid development of the ethylene oligomerization industry is largely due to the development of its catalyst and the huge application of α-olefin and polyethylene in today's life and industry. The method of a main industrial production linear alpha olefin is to apply SHOP type catalyst at present, and its structure is shown in the following formula (Angew.Chem., Int.Ed.Engl.1978,17,466-467; Angew.Chem., Int. Ed. Engl. 1983, 22, 503; J. Chem. Soc., Chem. Commun. 1994, 2203-2204): and Ziegler-Natta type catalysts (DE patent, 889229.1953-09-07; IT patent, 545332.1954; IT patent, 536899.1955; Belg patent, 533326.1955-05-05; Angew chem.1955, 67, 541-547; J Polym Sci PartA : Chem, 1955, 16: 143-154), Phillips type catalyst (Belg patent 530617.1955; US patent, 2825721.1958-03-04; Adv Catalysis, 1985, 33: 47-56) and metallocene type catalyst (Metalorgani...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F15/04B01J31/22C07C2/32C07C11/08C08F110/02C08F4/70

Inventor 金永利曾艳宁余建刚

Owner 金永利

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com