Catalyst system for in-situ copolymerizing linear low-density polyethylene

A copolymerization catalyst and a linear low-density technology are applied in the field of catalyst systems for in-situ copolymerization to prepare linear low-density polyethylene, and can solve the problem of high cost of copolymerization catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) All operations are carried out under anhydrous and oxygen-free conditions, and all solvents require dehydration and deoxygenation treatment.

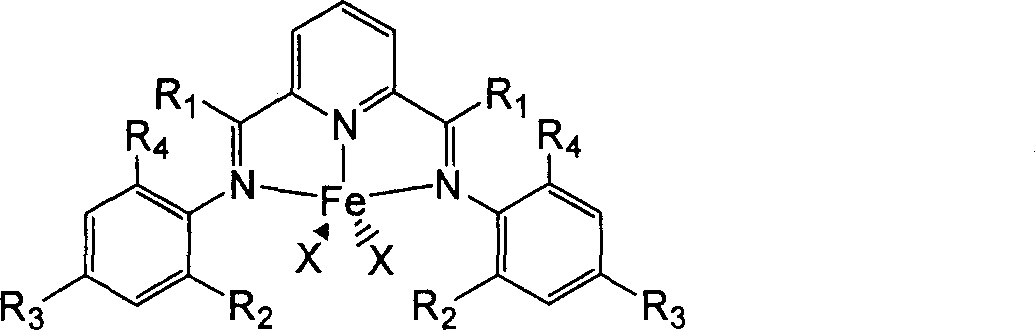

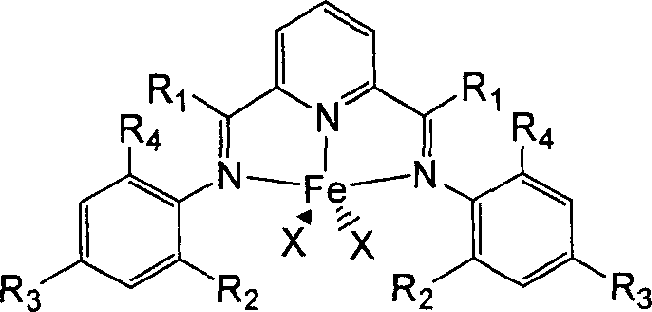

[0031] 2) A: Oligomerization catalyst

[0032]

[0033] B: The oligomerization cocatalyst is MAO

[0034] C: Copolymerization catalyst TiCl 4 / MgCl 2 (Ti=4.5%)

[0035] D: Co-catalyst triethylaluminum (TEA)

[0036] 3) Replace a 5L stainless steel reactor with anchor stirring with nitrogen and ethylene respectively, add 2L of hexane under the protection of ethylene, add MAO [Al / Fe=1500:1 (molar ratio)] under stirring, and stir for 1 minute , adding 5.0×10 -6 mol oligomerization catalyst A, react at 20°C for 4 minutes.

[0037] 4) Add TEA (Al / Ti=50) and 95.8 mg (90×10 -6 mol) Copolymerization of the main catalyst C, after heating up to 70°C, feed hydrogen until the pressure of the reactor rises by 0.15MPa, then start to feed ethylene into the reactor to 0.4MPa, and use ethylene to maintain the pressure in the reactor,...

Embodiment 2

[0043] 1) All operations are performed under anhydrous and oxygen-free conditions, and all solvents require dehydration and deoxidation treatment.

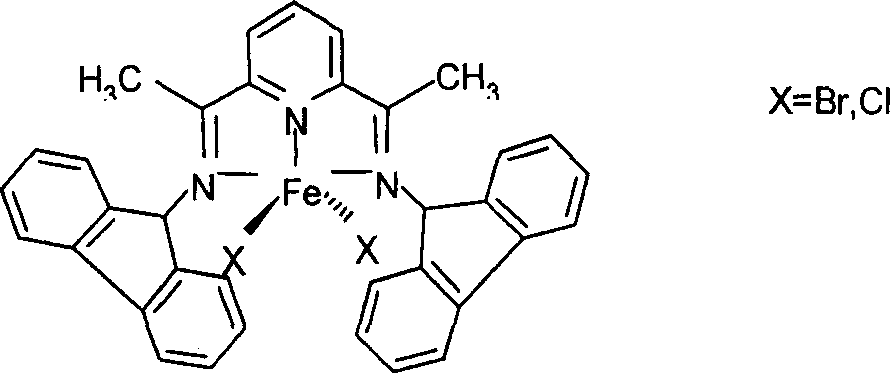

[0044] 2) A: Oligomerization procatalyst supported by montmorillonite

[0045]

[0046] B: oligomerization promoter MAO

[0047] C: Copolymerization main catalyst TiCl 4 / MgCl 2 (Ti=4.5%)

[0048] D: Co-catalyst triethylaluminum (TEA)

[0049] 3) A 5L stainless steel reactor with anchor stirring was replaced with nitrogen and ethylene respectively, 2L of hexane was added under the protection of ethylene, MAO [Al / Fe=1000:1 (molar ratio)] was added under stirring, and after stirring for 1 minute, Add 0.2g (5.0×10 -6 mol) oligomerization catalyst A, react at 20°C for 10 minutes.

[0050] 4) Add TEA (Al / Ti=50) and 95.8 mg (90×10 -6 mol) Copolymerize the main catalyst C. After the temperature is raised to 70°C, hydrogen is introduced until the pressure of the reactor rises by 0.15 MPa. Then, ethylene is introduced into the re...

Embodiment 3

[0055] 1) All operations are carried out under anhydrous and oxygen-free conditions, and all solvents require dehydration and deoxygenation treatment.

[0056] 2) A: Oligomerization catalyst

[0057]

[0058] B: oligomerization promoter MAO

[0059] C: Copolymerization main catalyst TiCl 4 / MgCl 2 (Ti=5.6%)

[0060] D: co-catalyst TEA

[0061] 3) A 5L stainless steel reactor with anchor stirring was replaced with nitrogen and ethylene respectively, 2L of hexane was added under the protection of ethylene, MAO [Al / Fe=2000:1 (molar ratio)] was added under stirring, and after stirring for 1 minute, Join 8.0×10 -6 mol oligomerization catalyst A, react at 20°C for 8 minutes.

[0062] 4) Add TEA (Al / Ti=75) and 42.8mg (50×10 -6 mol) Copolymerization of the main catalyst C, after heating up to 70°C, feed hydrogen until the pressure of the reactor rises by 0.10MPa, then start to feed ethylene into the reactor to 0.4MPa, and use ethylene to maintain the pressure in the reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com