Method for grafting maleic anhydride with bisphenol A epoxy resin free radicals

A technology of grafting maleic anhydride and epoxy resin, which is applied in the field of epoxy resin modification, and can solve the problems of reducing the excellent performance of epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 100g of E-20 type epoxy resin, add 75g of dioxane as solvent, heat to 50°C and stir to make the epoxy resin completely dissolved. Warm up to 90°C, add 30g maleic anhydride and 5g benzoyl peroxide, stir at constant temperature, maleic anhydride and benzoyl peroxide are added 3 times (there is no special requirement for each addition, the following examples are the same), The interval time is 3h. After the feeding is completed, the constant temperature reaction is continued for 3 hours, and the material is discharged to obtain the grafted product.

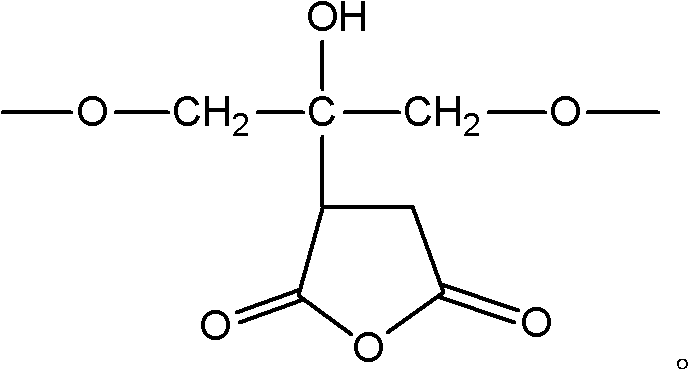

[0020] The graft product molecule contains both epoxy groups and anhydride groups with the following structure:

[0021]

[0022] The structure of the product was characterized by infrared spectroscopy, 1778.45cm -1 There is an obvious characteristic absorption peak of acid anhydride, indicating that maleic anhydride has been grafted onto the epoxy resin molecular chain; 915.46cm -1 And 831.04cm -1 It is the characteristic ab...

Embodiment 2

[0024] Take 100g of E-12 type epoxy resin, add 75g of dioxane as solvent, heat to 60°C, stir to make the epoxy resin completely dissolved. The temperature was raised to 90° C., 30 g maleic anhydride and 5 g benzoyl peroxide were added, and the mixture was stirred at constant temperature. Maleic anhydride and benzoyl peroxide were added in 3 portions with an interval of 3 hours. After the feeding is completed, the constant temperature reaction is continued for 3 hours, and the material is discharged to obtain the grafted product.

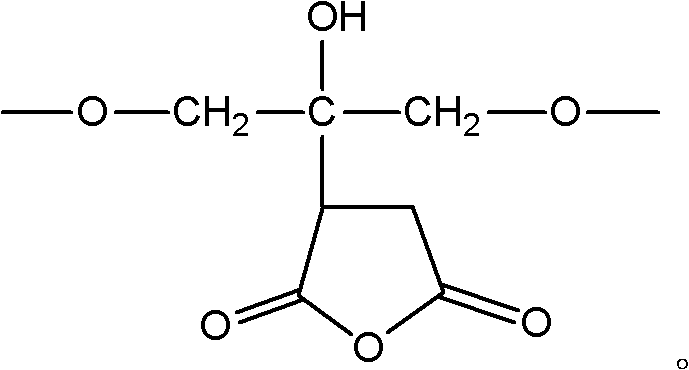

[0025] The graft product molecule contains both epoxy groups and anhydride groups with the following structure:

[0026]

[0027] The structure of the product was characterized by infrared spectroscopy, 1778.45cm -1 There is an obvious characteristic absorption peak of acid anhydride, indicating that maleic anhydride has been grafted onto the epoxy resin molecular chain; 915.46cm -1 And 831.04cm -1 It is the characteristic absorption peak of epoxy groups,...

Embodiment 3

[0029] Take 100g of E-10 type epoxy resin, add 75g of dioxane as a solvent, heat to 70°C and stir to completely dissolve the epoxy resin. The temperature was raised to 90° C., 30 g maleic anhydride and 5 g benzoyl peroxide were added, and the mixture was stirred at constant temperature. Maleic anhydride and benzoyl peroxide were added in 3 portions with an interval of 3 hours. After the feeding is completed, the constant temperature reaction is continued for 3 hours, and the material is discharged to obtain the grafted product.

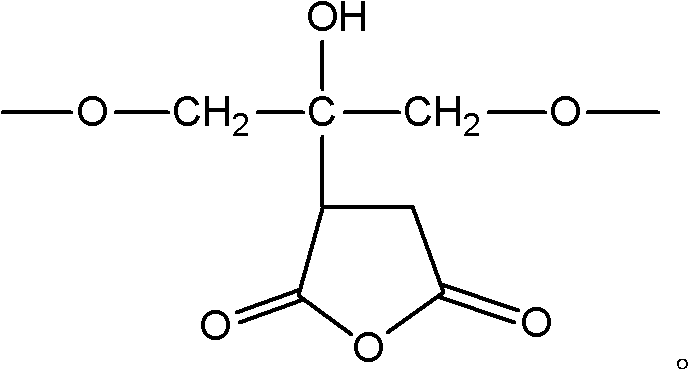

[0030] The graft product molecule contains both epoxy groups and anhydride groups with the following structure:

[0031]

[0032] The structure of the product was characterized by infrared spectroscopy, 1778.45cm -1 There is an obvious characteristic absorption peak of acid anhydride, indicating that maleic anhydride has been grafted onto the epoxy resin molecular chain; 915.46cm -1 And 831.04cm -1 It is the characteristic absorption peak of epoxy groups, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com