Fish-spear type electrolytic bath electrode

An electrolytic cell and harpoon technology, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of large energy dissipation and low electrolysis efficiency, and achieve the effect of reducing energy dissipation and improving electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

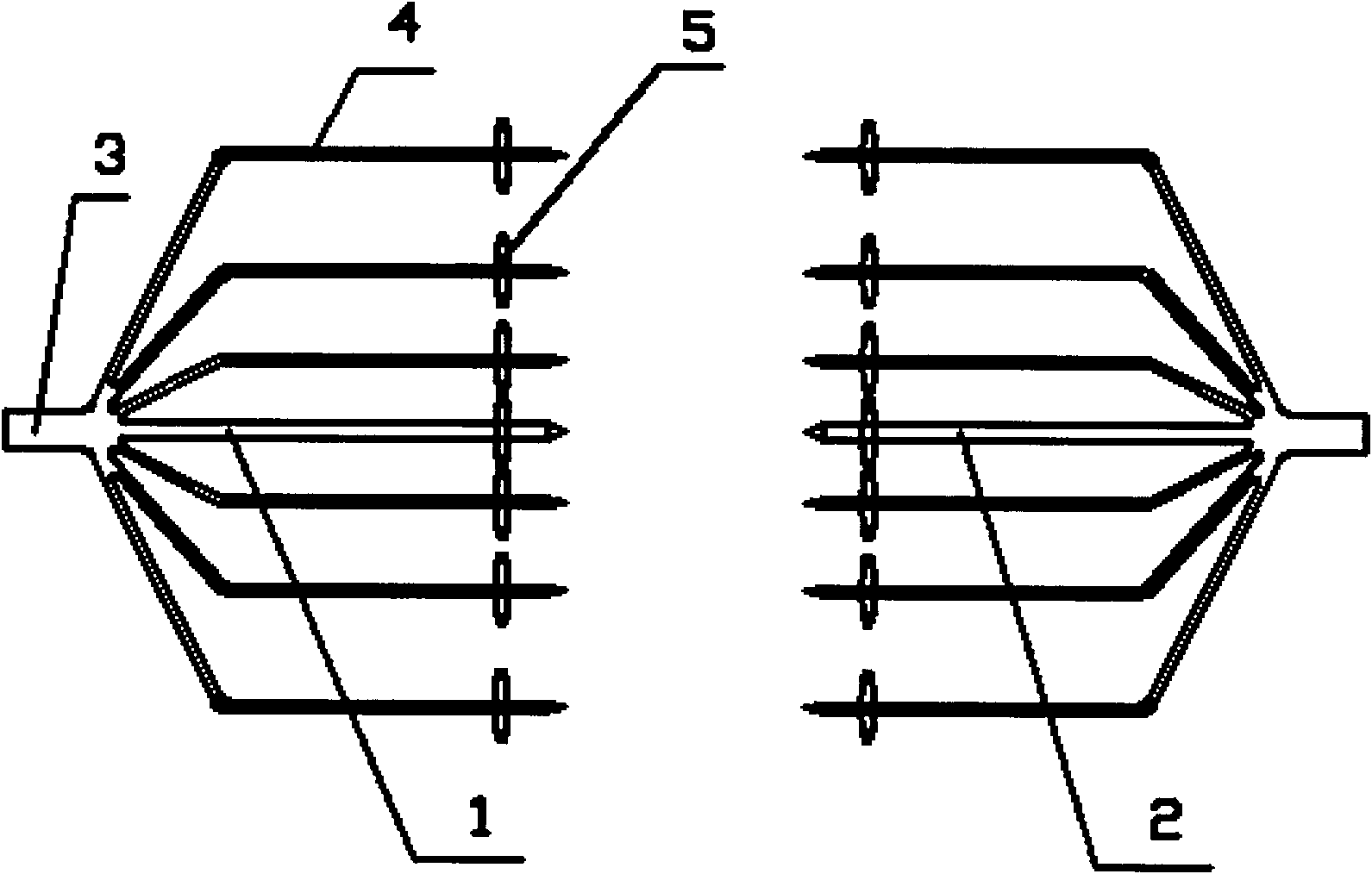

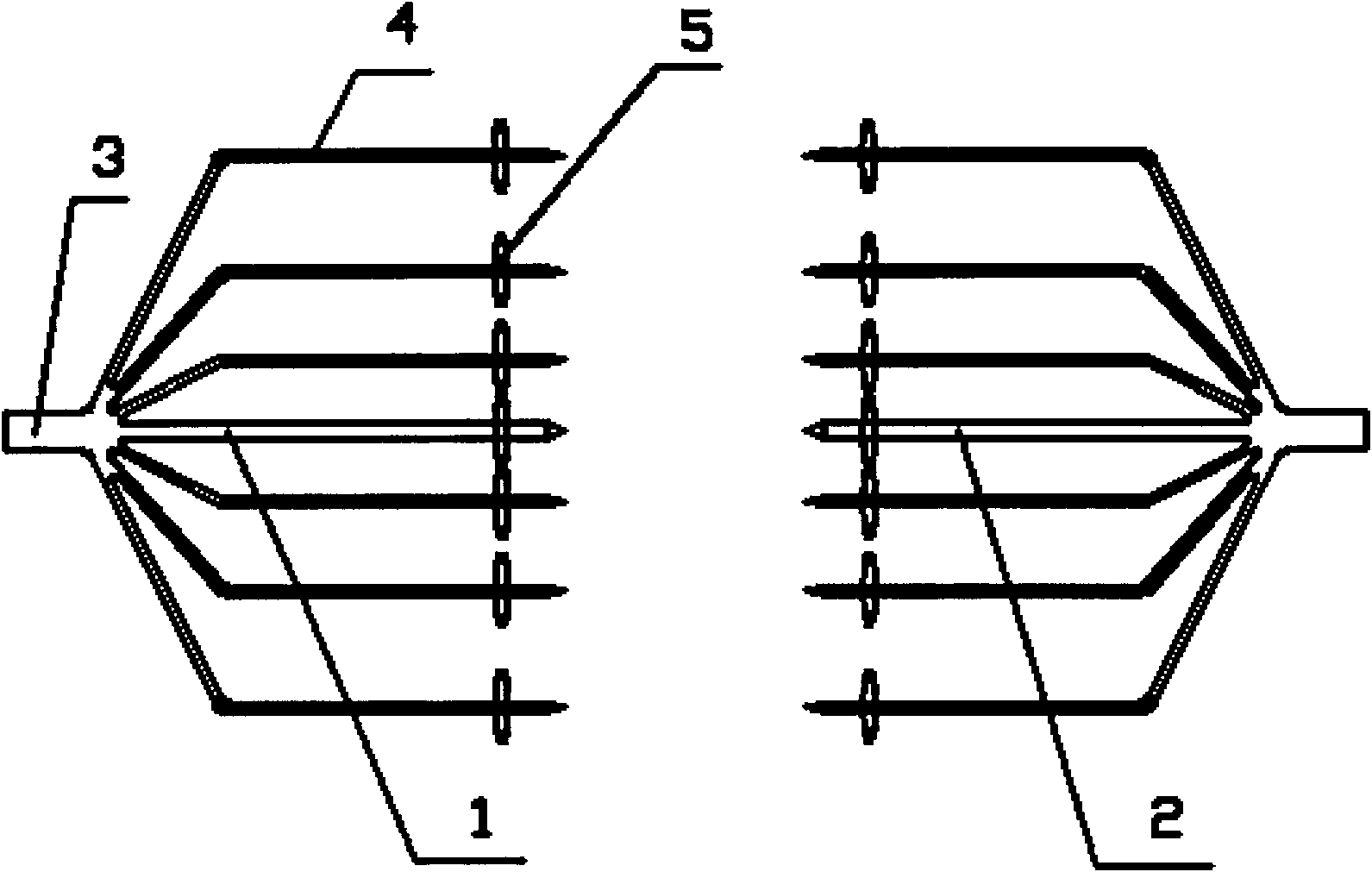

[0009] In the embodiment shown in the accompanying drawings, the electrode of the harpoon electrolyzer includes a positive electrode 1 and a negative electrode 2. The positive electrode 1 and the negative electrode 2 have the same shape and structure, both of which are harpoon-shaped. 3. Composed of fork pins 4 and conductor discs 5, the fork pins 4 are distributed on the electrode connector 3 in a harpoon shape, and each fork pin 4 is provided with a conductor disc 5, each Each conductor plate 5 on the fork needle 4 is perpendicular to the fork needle 4, and each conductor plate 5 is coplanar, and the positive and negative electrodes are oppositely arranged in the electrolytic cell.

[0010] For the above-mentioned harpoon-type electrolyzer electrode, the materials of the fork needle 4 and the conductor disc 5 of the positive electrode 1 are both titanium-based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com