Integrally combined differential lock

A differential lock, integrated technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex overall structure, inflexible return, piston sticking, etc., and achieve simplified parts structure, reduce the number of products, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

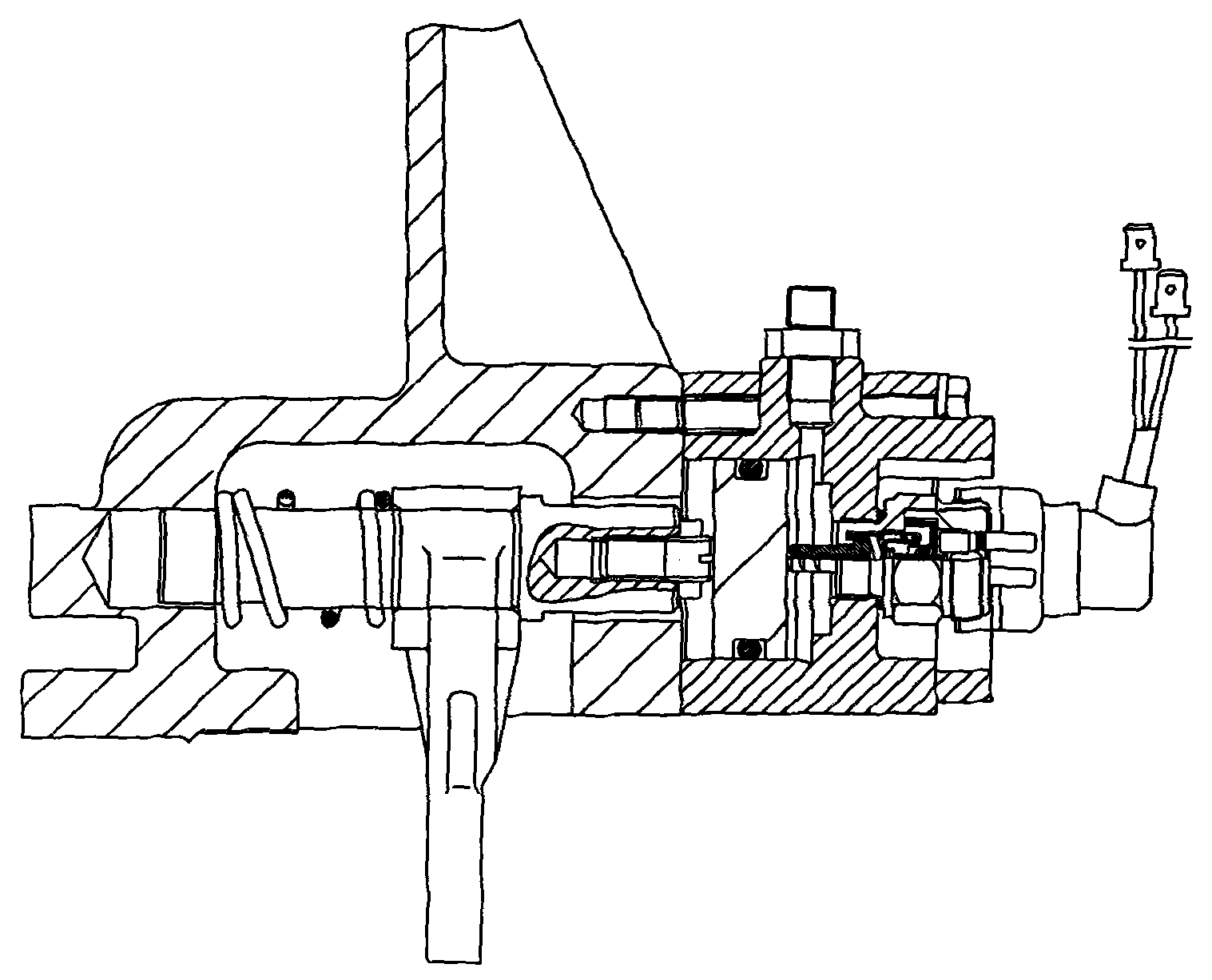

[0014] like figure 1 Shown is a schematic structural diagram of a differential lock in the prior art;

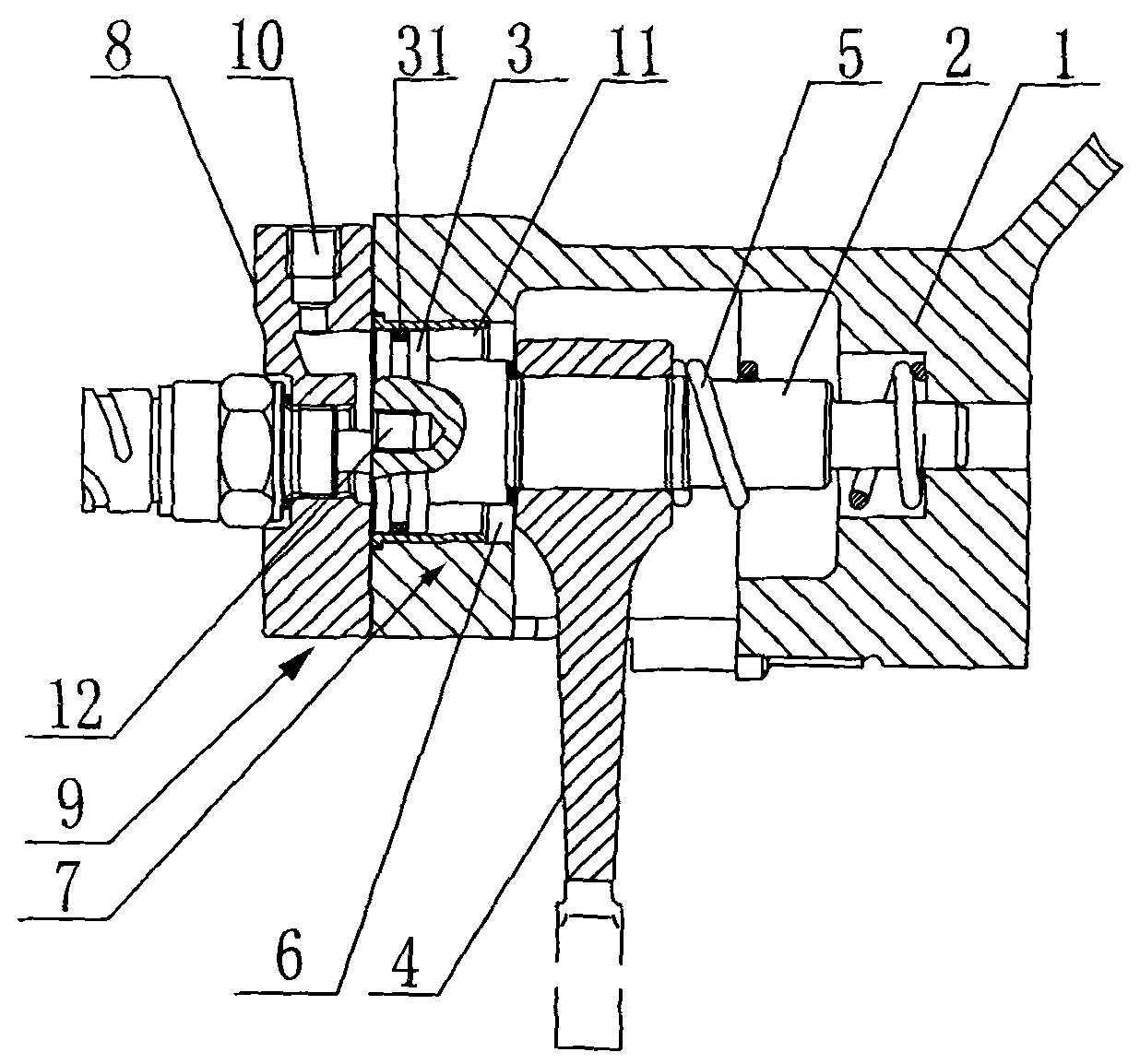

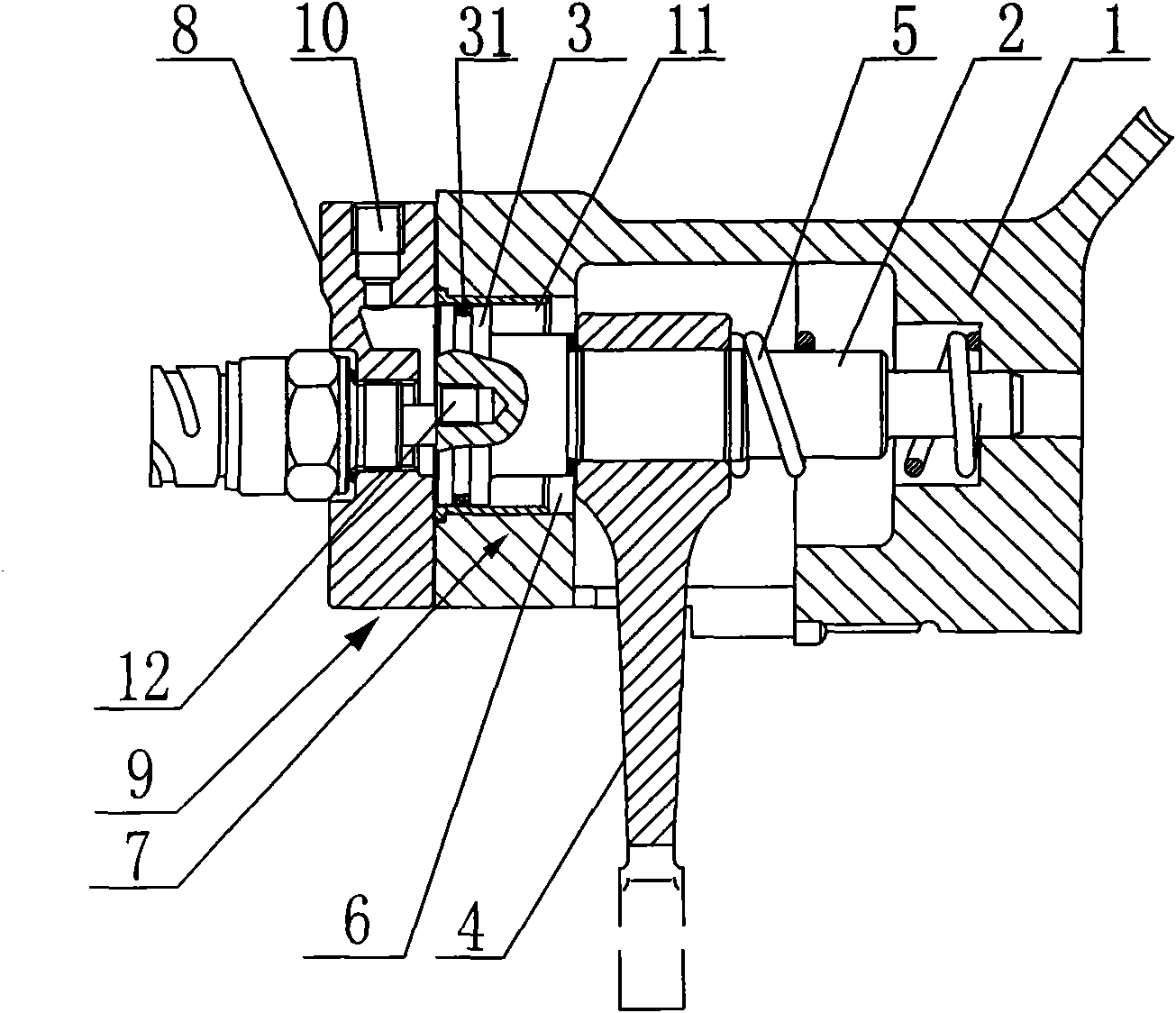

[0015] like figure 2 Shown is a schematic structural view of the integrated differential lock of the present invention, an integrated differential lock, including a housing 1, a shift fork shaft 2, and a piston 3 connected to the shift fork shaft 2, and a cylindrical groove in the piston 3 A leather cup 31 for enhancing the working performance of the cylinder is installed inside, a shift fork 4 is sleeved on the shift fork shaft 2, and a return spring 5 interacting with the housing 1 is sleeved on the shift fork shaft 2, the return spring 5 In the non-working state, it is in a compressed state and leans against the shift fork 4. The housing 1 is provided with a cavity 6 corresponding to the position of the piston 3. The inner wall of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com