Processing method of eccentric sphere embedded plastic ball valve and product thereof

A technology of plastic ball valve and processing method, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of difficult valve switching operation, negative changes in ball valve assembly size, sealing failure, etc., to solve the difficulty of accurate opening and closing limit , Solve the problem of long-term sealing, and ensure the effect of opening and closing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

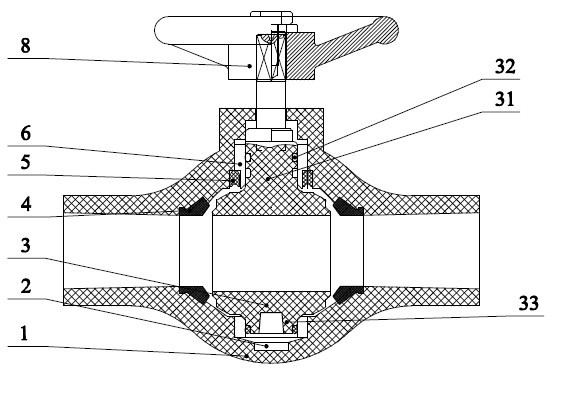

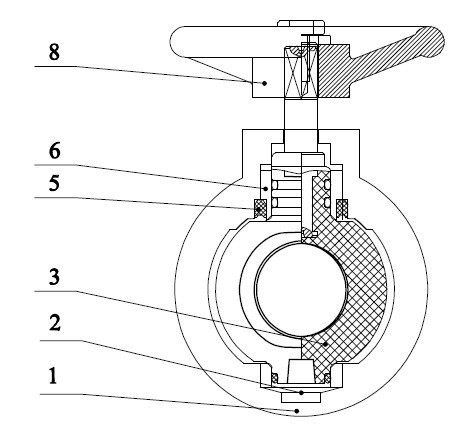

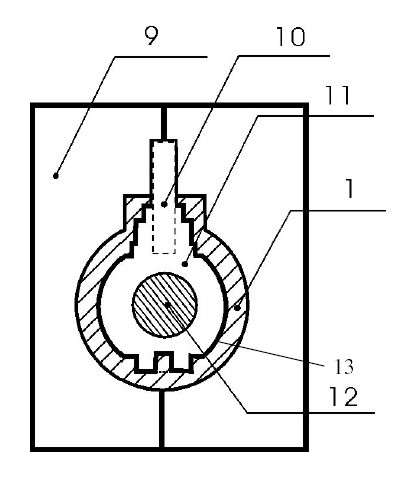

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a valve body 1, a lower shaft sleeve 2, an eccentric sphere 3, a plastic valve seat 4, a special-shaped sealing ring 5, an upper shaft sleeve 6, and a driving mechanism 8 for driving the rotation of the sphere.

[0033] The eccentric sphere 3 is molded by plastic casting; the upper end of the eccentric sphere 3 is provided with an upper shaft handle 31, and the upper shaft handle 31 is inserted into a combined seal composed of an O-shaped sealing ring 32, an upper shaft sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com