Full-floating mandrel tandem-rolling seamless steel pipe production process

A technology of seamless steel pipe and production process, applied in the direction of metal rolling, etc., can solve the problems of low production efficiency, high consumption, high pollution, etc., and achieve the effect of fast rolling rhythm, high output and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

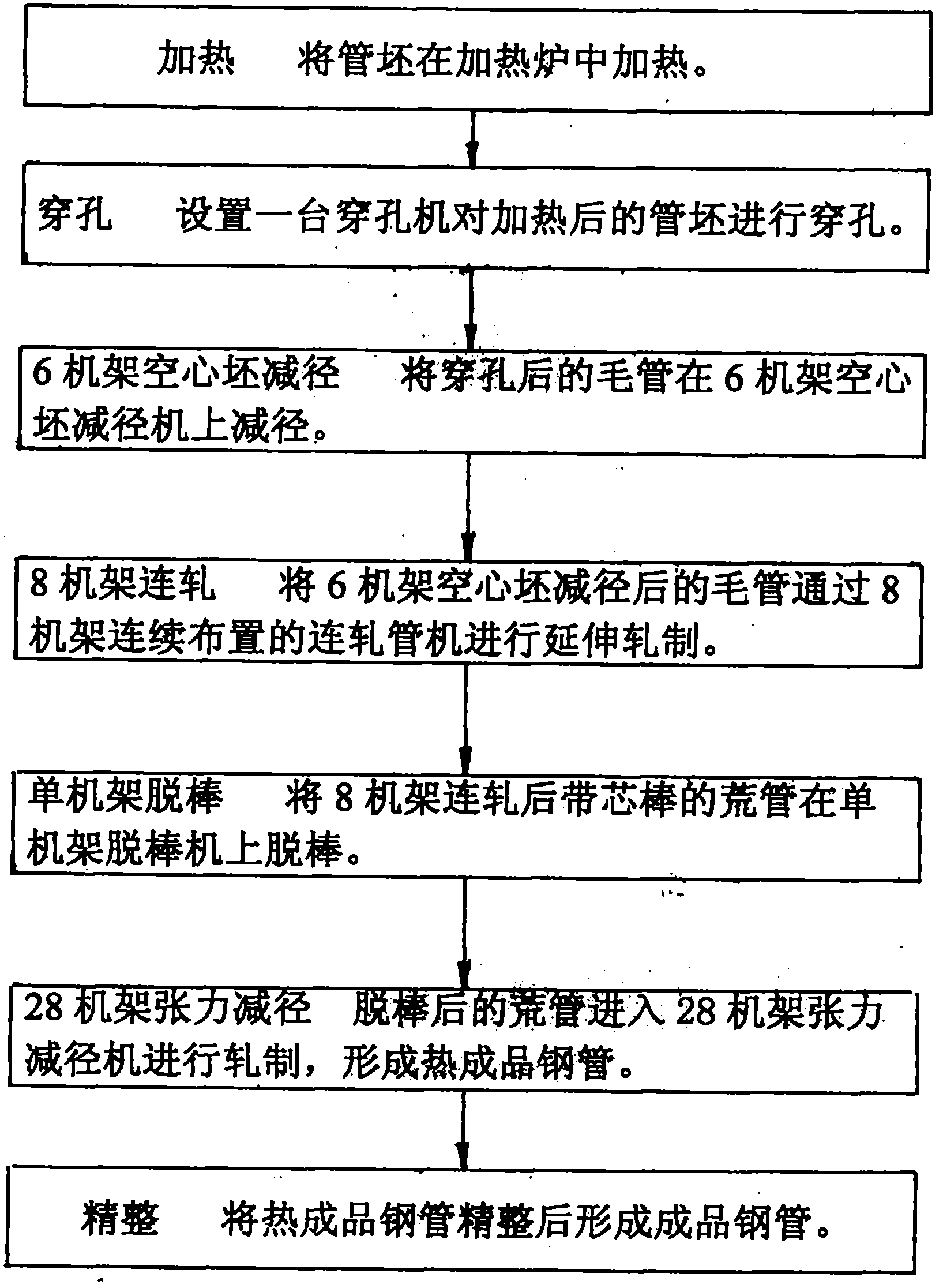

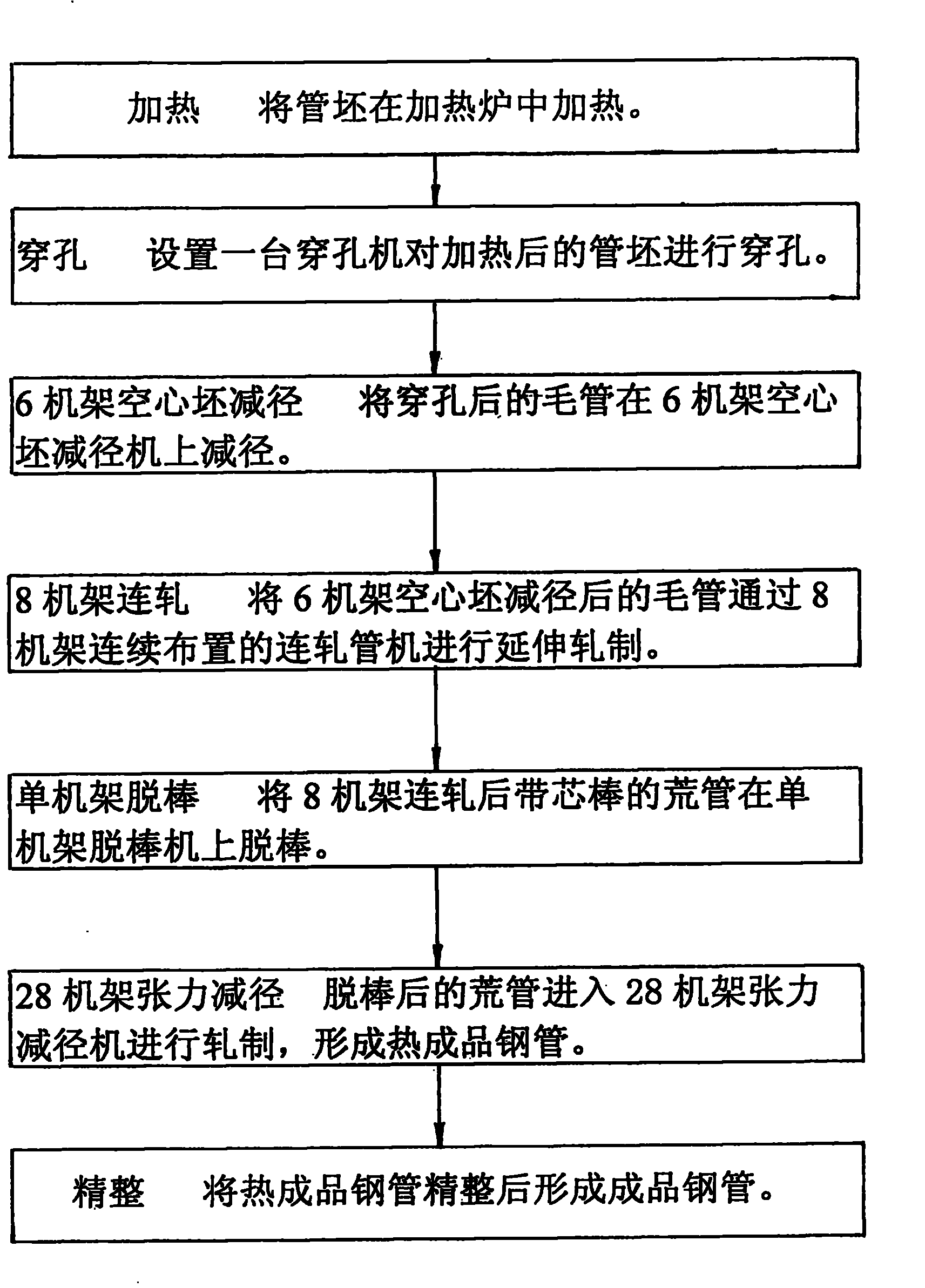

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, the full-floating mandrel continuous rolling seamless steel pipe production process provided by the present invention comprises the following steps:

[0024] Heating The tube blank is heated in a heating furnace.

[0025] The heating furnace can be an inclined bottom heating furnace, an annular heating furnace, or a walking heating furnace, and the heating temperature range is 1100-1280°C;

[0026] Piercing Set up a piercing machine to perforate the heated tube blank.

[0027] The perforator can be a vertical fungus perforator or a Diesel vertical perforator;

[0028] 6-frame hollow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com