A Method to Solve the Wrinkles of Thin Strip Steel in the Process of Coiling and Threading

A thin strip steel, take-and-thread strip technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve problems such as unqualified steel coil products, strip threading wrinkles, coiling thin strip steel wrinkles, etc., to improve Effects of quality, reduced shock, fast rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

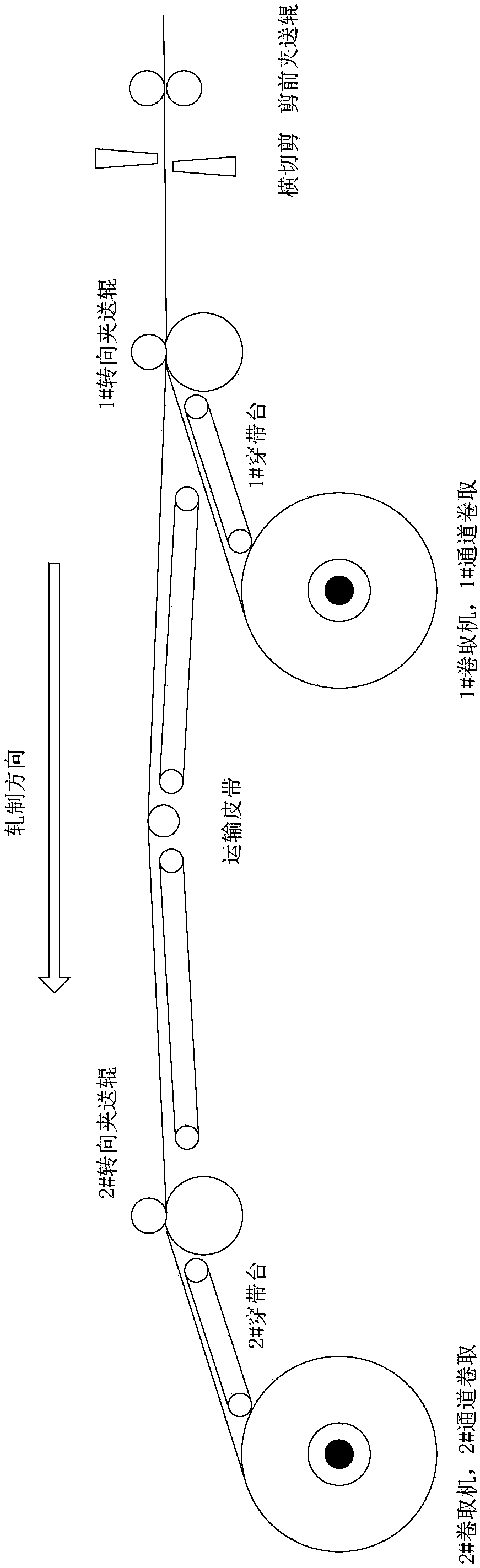

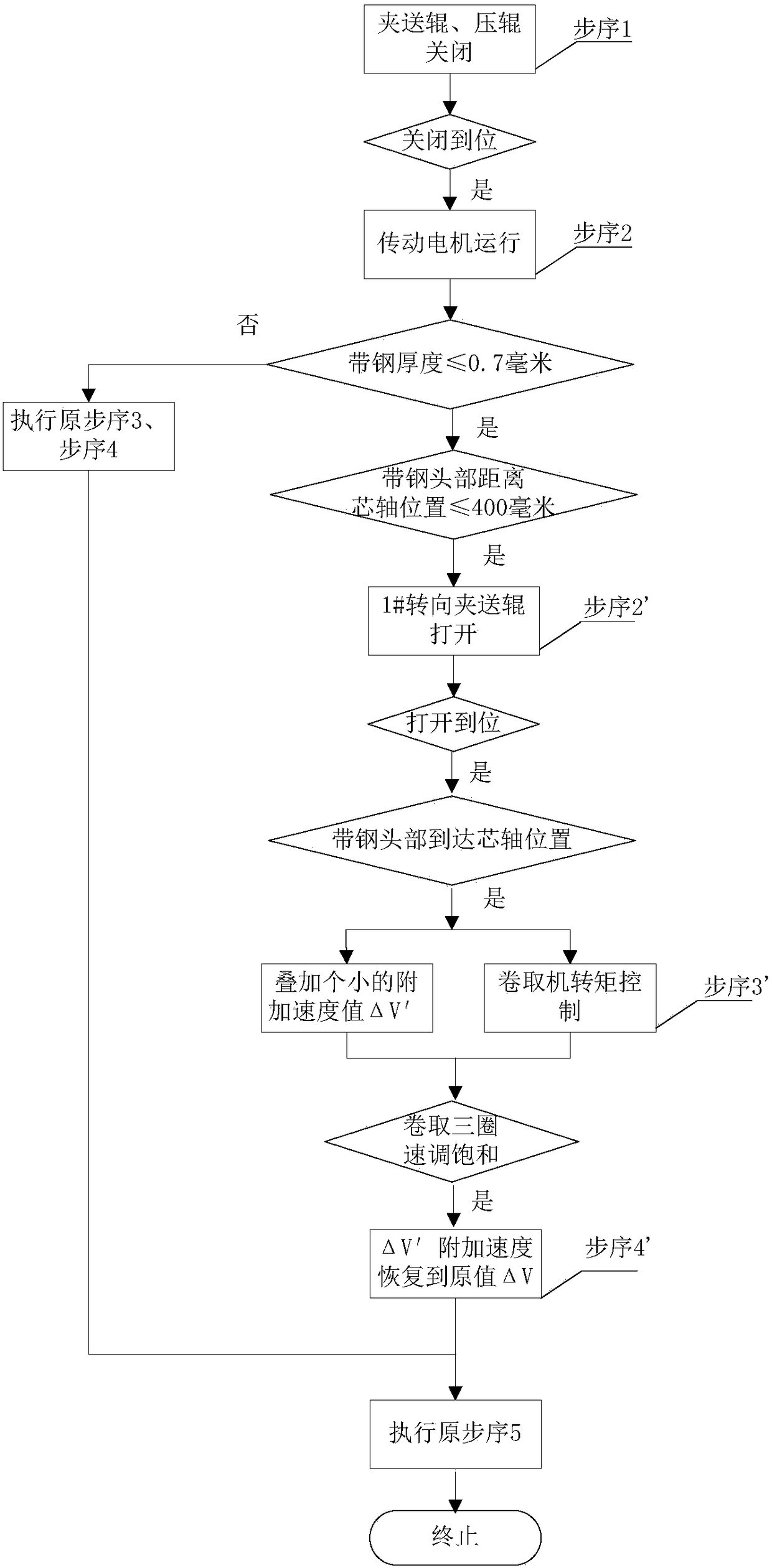

[0036] The following is an analysis of the automatic belt threading process of the exit coiler of a company's galvanized production line to illustrate the control effect of adding the pre-control function of the steering pinch roller and reducing the added value of the speed.

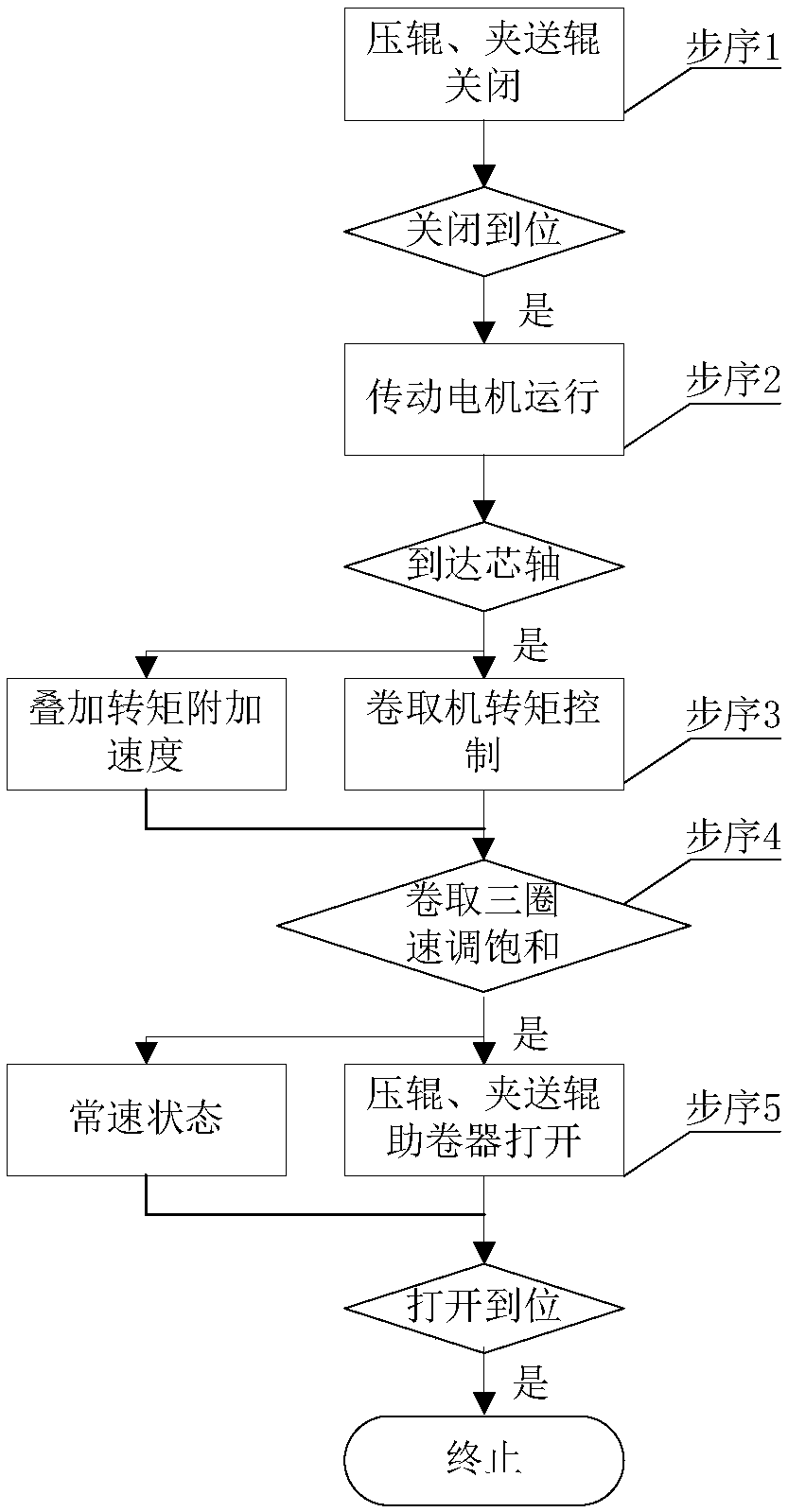

[0037] In the production process, after the export coiling preparation sequence is completed, follow the usual automatic belt threading control process (such as figure 2 shown) for automatic threading, when using 2# coiler to coil the steel strip below 0.7mm in thickness, when the head of the strip reaches the shaft position of 2# coiler and the coiler switches to the torque control process , it is obvious to see that there is a wrinkle with a distance of about 2 meters on the drive side of the 1# turning pinch roller. During the continuous coiling process, it can be seen that there are wrinkles in the coiling circles, which seriously affects the coiling quality. After this kind of situation takes pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com