Half-shaft pre-upsetting cooling system

A cooling system and pre-pier technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of reducing the service life of the mold, high working frequency, uneven cooling of the mold, etc. Achieve the effects of reducing thermal expansion cracking, prolonging service life, and reducing difficulty in demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

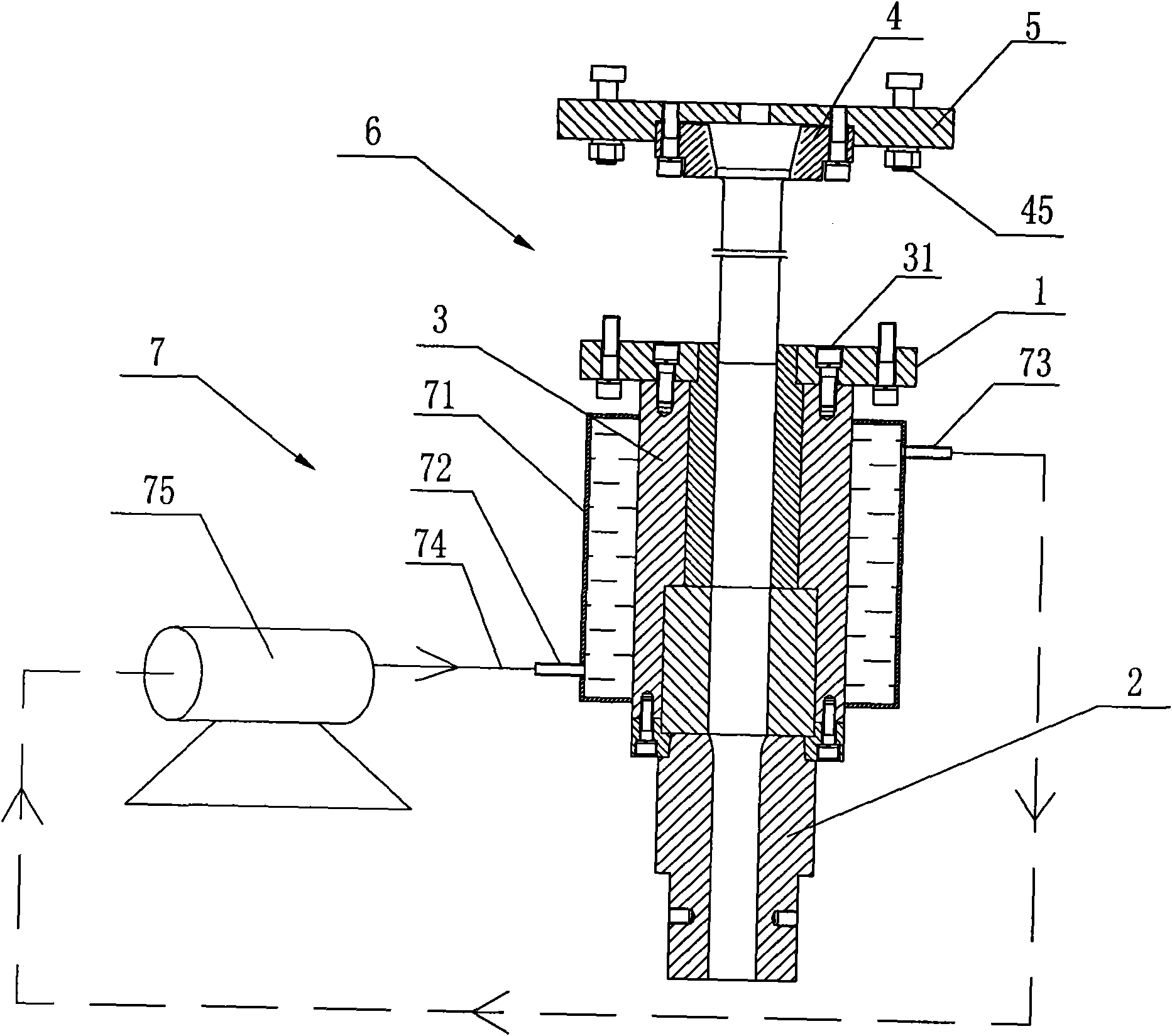

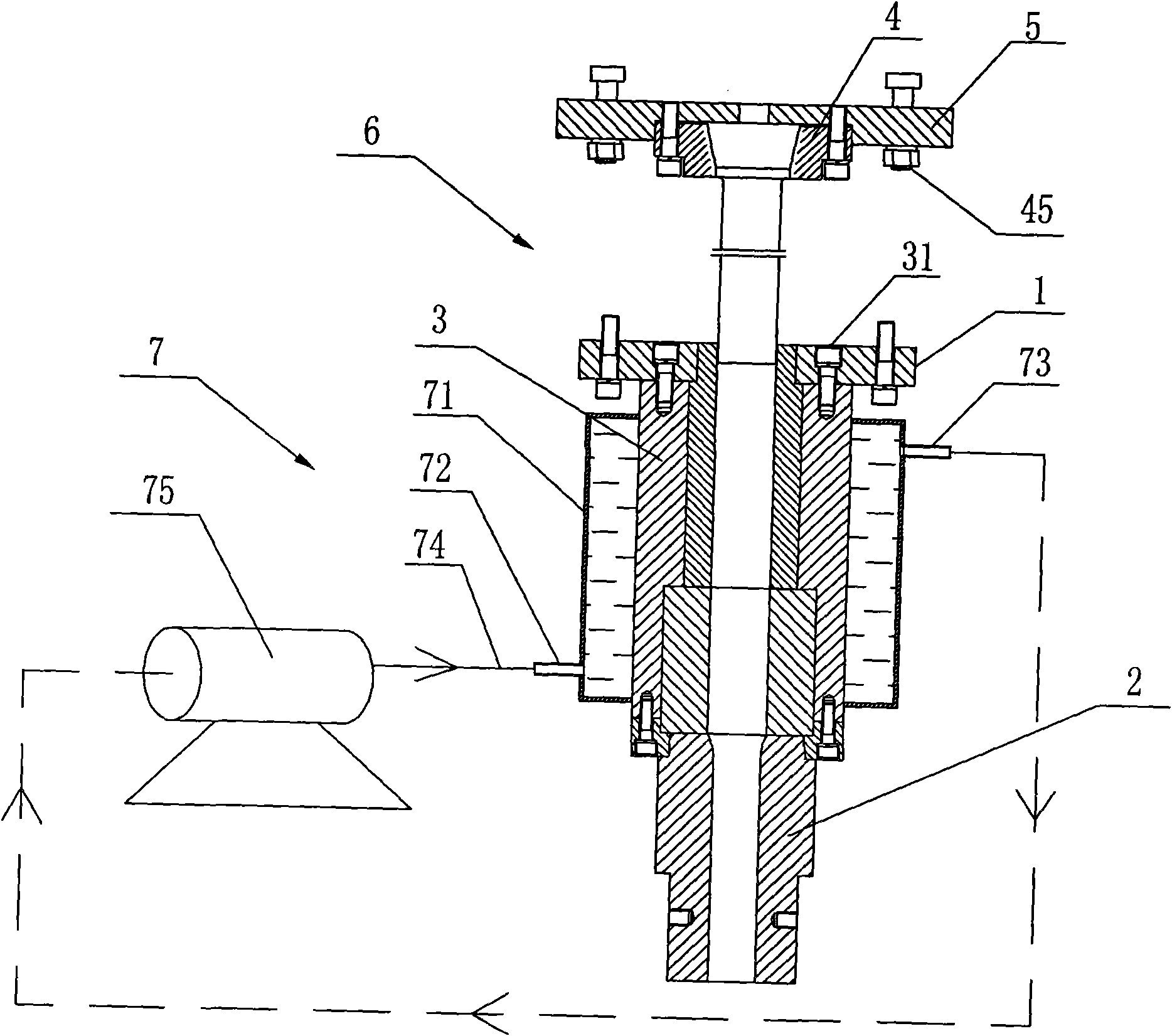

[0010] Such as figure 1 As shown, it is a front view of the semi-axis pre-pier cooling system of the present invention, which includes a pre-pier mold 6 composed of a fixed plate 1, a clamping block 2, a mold protection sleeve 3, an inner insert 4, and an outer insert 5. The fixed plate 1 is connected to the mold protective sleeve 3 through the first screw 31, and the clamping block 2 is arranged in the mold protective sleeve 3, and is embedded with the mold protective sleeve 3 through the fixed plate 1. The inner insert 4, the outer insert The block 5 clamps the pre-pier parts and fixes them with the second screw 45; the mold protective sleeve 3 is provided with a circulating cooling device 7.

[0011] The circulating cooling device 7 includes a circulating water tank 71 arranged outside the mold protective cover 3, and a water inlet 72 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com