Amide group-containing hydroxysulfobetaine and preparation and application thereof

A technology containing amide group hydroxysulfobeet and amide group hydroxysulfobeet is applied in the directions of sulfonate preparation, chemical instrument and method, drilling composition, etc., and can solve the problem of poor salt tolerance of anionic surfactants , poor stability, non-ionic surfactants are not resistant to high temperature and other problems, to achieve the effect of improving oil recovery, good temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the synthesis of erucic acid amido sulfobetaine

[0029] Put 0.1 mol of erucic acid and 0.1 mol of N,N-dimethyl-1,3-propanediamine into a high-pressure reactor, keep the temperature at 200° C., and react for 3 hours. Mix 0.1 mol of tertiary amine containing erucamide group obtained by the reaction with 0.1 mol of sodium 3-chloro-2-hydroxypropanesulfonate, keep the temperature at 80° C., and react for 3 hours to obtain erucamide hydroxysulfobetaine. The obtained product was separated and purified, and the calculated conversion rate was 95.3%.

[0030]

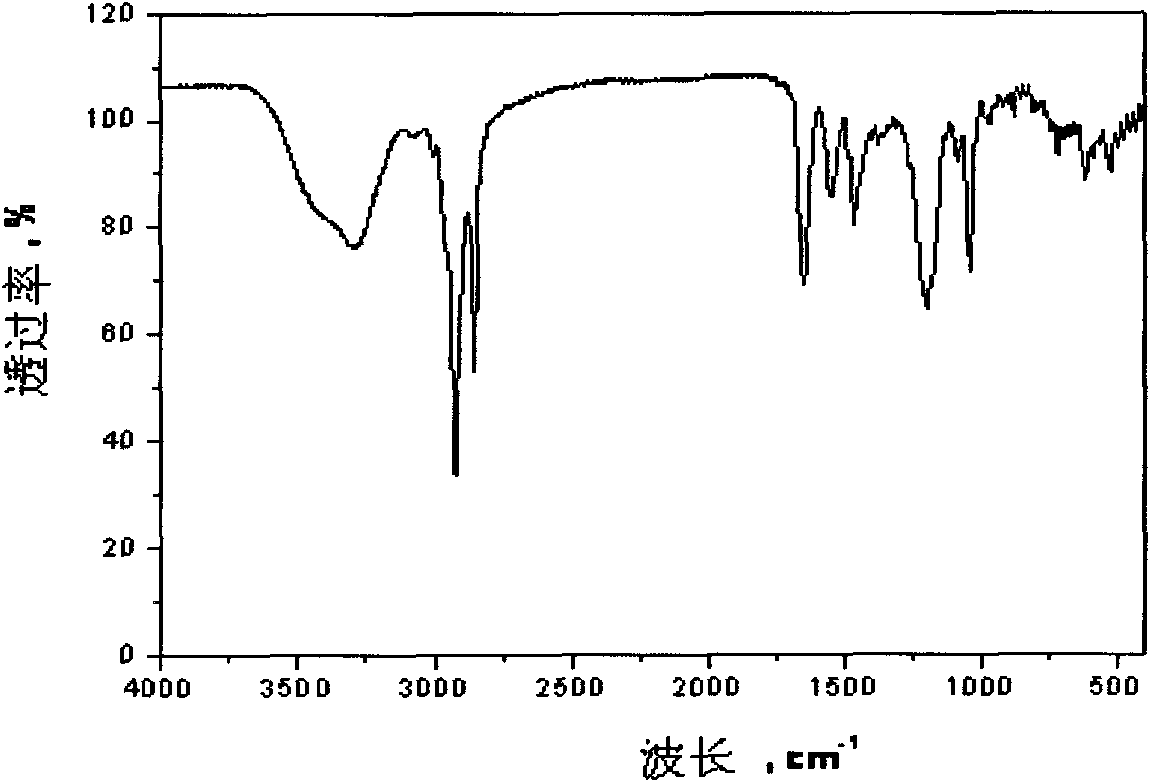

[0031] Infrared analysis was carried out to the obtained product, and the test results were as follows: figure 1 shown. It can be seen that 3400cm -1 The nearby peak is O-H stretching vibration, 3350cm -1 and 3180cm -1 Nearby is the characteristic peak of N-H stretching vibration, 2900cm -1 Nearby is CH 2 The characteristic peak of the antisymmetric stretching vibration, 1470cm -1 at CH 2 The sci...

Embodiment 2

[0032] Embodiment 2: the synthesis of alkyl amido sulfobetaine

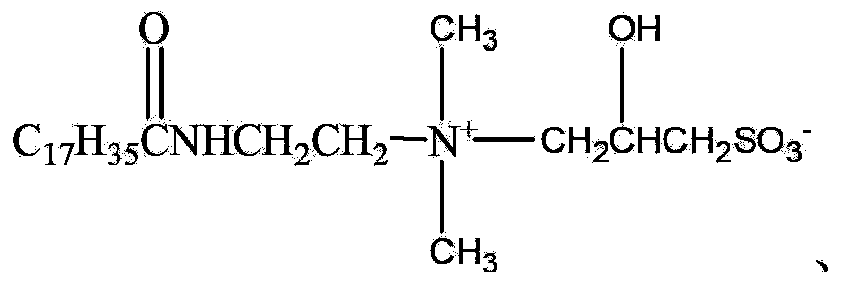

[0033] Put 0.1 mol of saturated octadecanoic acid and 0.1 mol of N,N-dimethyl-ethylenediamine into an autoclave, keep the temperature at 150° C., and react for 3 hours. Mix 0.1 mol of tertiary amines containing octadecylamide groups obtained by the reaction with 0.1 mol of 3-chloro-2-hydroxypropanesulfonate sodium, keep the temperature at 80°C, and react for 3 hours to obtain octadecylamide hydroxysulfonate base betaine. Separation and purification, the calculated conversion rate is 91.7%. Elemental analysis of the product (theoretical calculation value in brackets): C 60.85% (60.98%); H 10.72% (10.57%); N 5.86% (5.69%); S 6.67% (6.50%).

[0034]

Embodiment 3

[0035] Embodiment 3: the synthesis of octylphenyl amido sulfobetaine

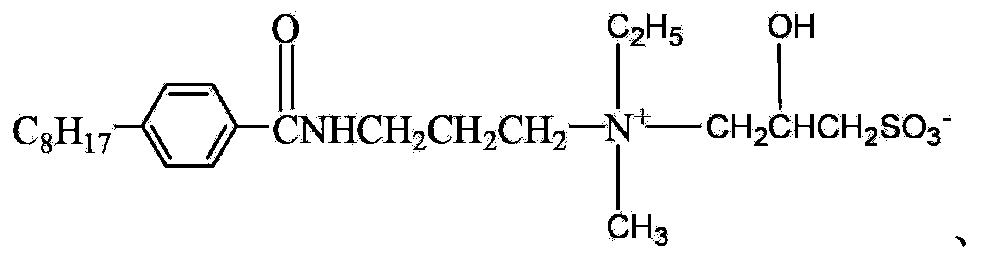

[0036] Put 0.1 mol of 4-octylbenzoic acid and 0.1 mol of N-methyl-N-ethyl-1,3-propanediamine into a high-pressure reactor, keep the temperature at 180°C, and react for 3 hours. Mix 0.1 mol of tertiary amine containing octylphenylamide group obtained by the reaction with 0.1mol of 3-chloro-2-hydroxypropanesulfonate sodium, keep the temperature at 80°C, and react for 3 hours to obtain octylphenylamidohydroxysulfonate Betaine. Separation and purification, the calculated conversion rate is 88.5%. Elemental analysis of the product (theoretical calculation value in brackets): C 61.41% (61.28%); H 8.73% (8.94%); N 6.12% (5.96%); S 6.93% (6.81%).

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com