High-strength composite grid

A composite grid, high-strength technology, applied in road construction reinforcements, roads, excavation, etc., can solve the problems of large elongation, difficulty in adapting to engineering requirements, and low strength, so as to achieve low creep and reduce engineering work The effect of high volume and high resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings:

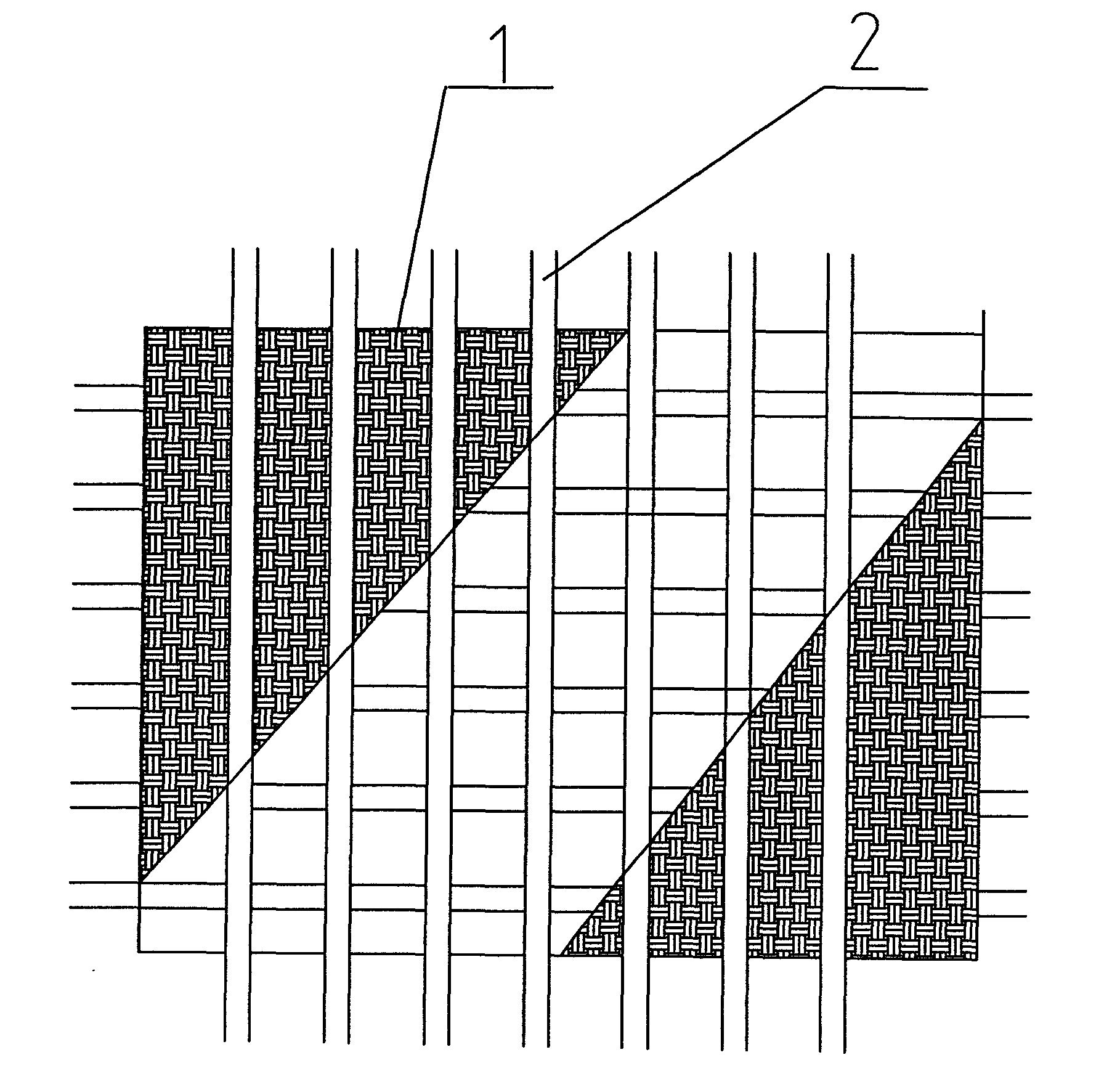

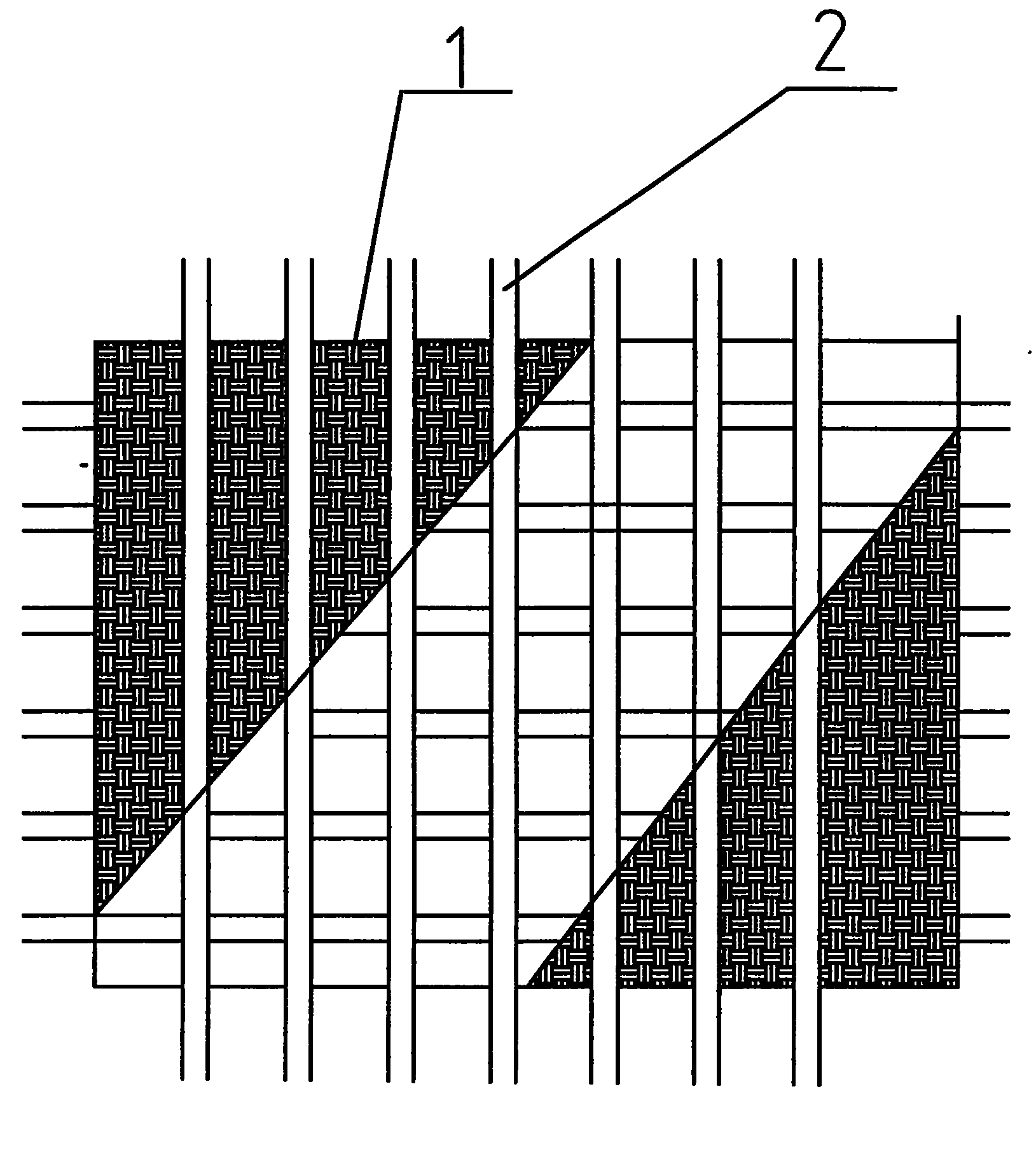

[0014] A high-strength composite grid, comprising a finely woven high-density polyethylene material geotextile 1 and a steel-plastic composite tie-bar 2, the steel-plastic composite tie-bar 2 is woven into a grid-like grid, and the steel-plastic composite tie The finely woven high-density polyethylene material geotextile 1 is laid in the grid-shaped grid woven by the rib tape 2, and the finely woven high-density polyethylene material geotextile 1 and the steel-plastic composite reinforced tape 2 are connected by ultrasonic welding.

[0015] The finely woven high-density polyethylene material geotextile 1 is formed by warp and weft weaving of synthetic fiber bundles.

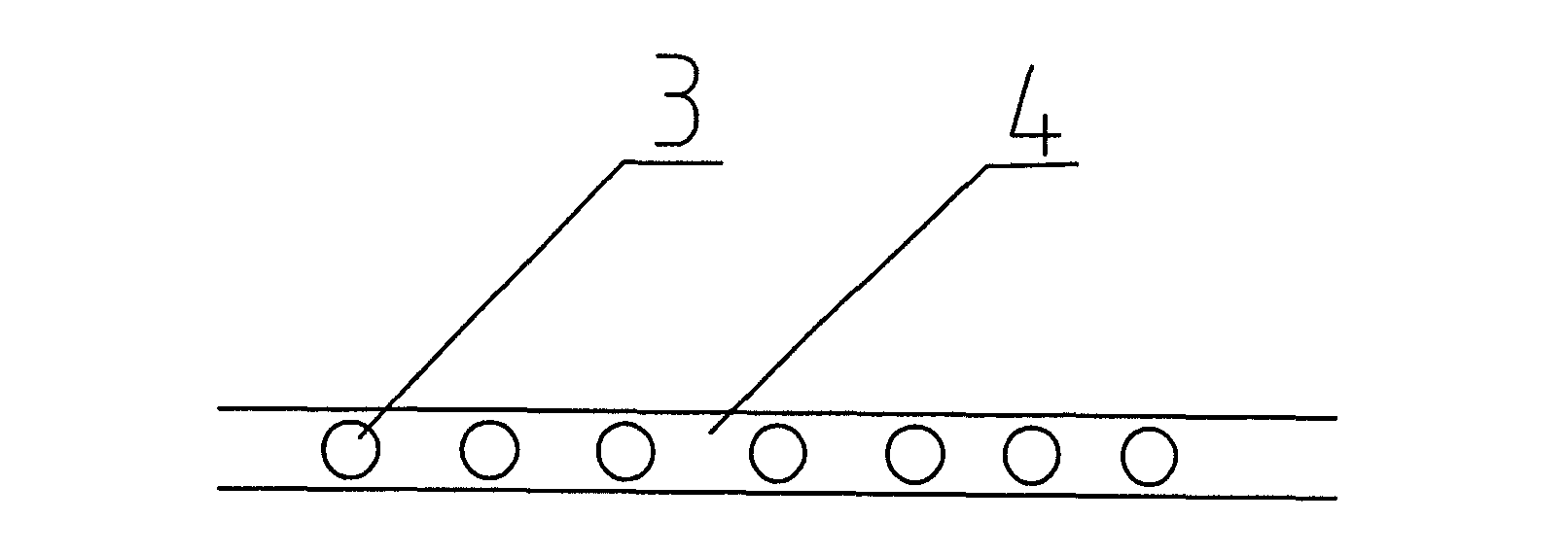

[0016] The steel-plastic composite reinforced tape 2 is made of steel wire 3 wrapped with high-density polyethylene 4.

[0017] The steel-plastic composite tie-bar 2 is made of steel wire 3 wrapped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com