Method for transforming tangent tower of double-circuit double-bundle transmission lines by lifting in electrified mode in another place

A transmission line, double-circuit technology, applied in the installation of overhead lines/cable equipment, electrical components, cables, etc., can solve problems such as unsuitable lines/poles and towers off-site displacement and reconstruction projects, to improve safety and reliability, reduce lifting load, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

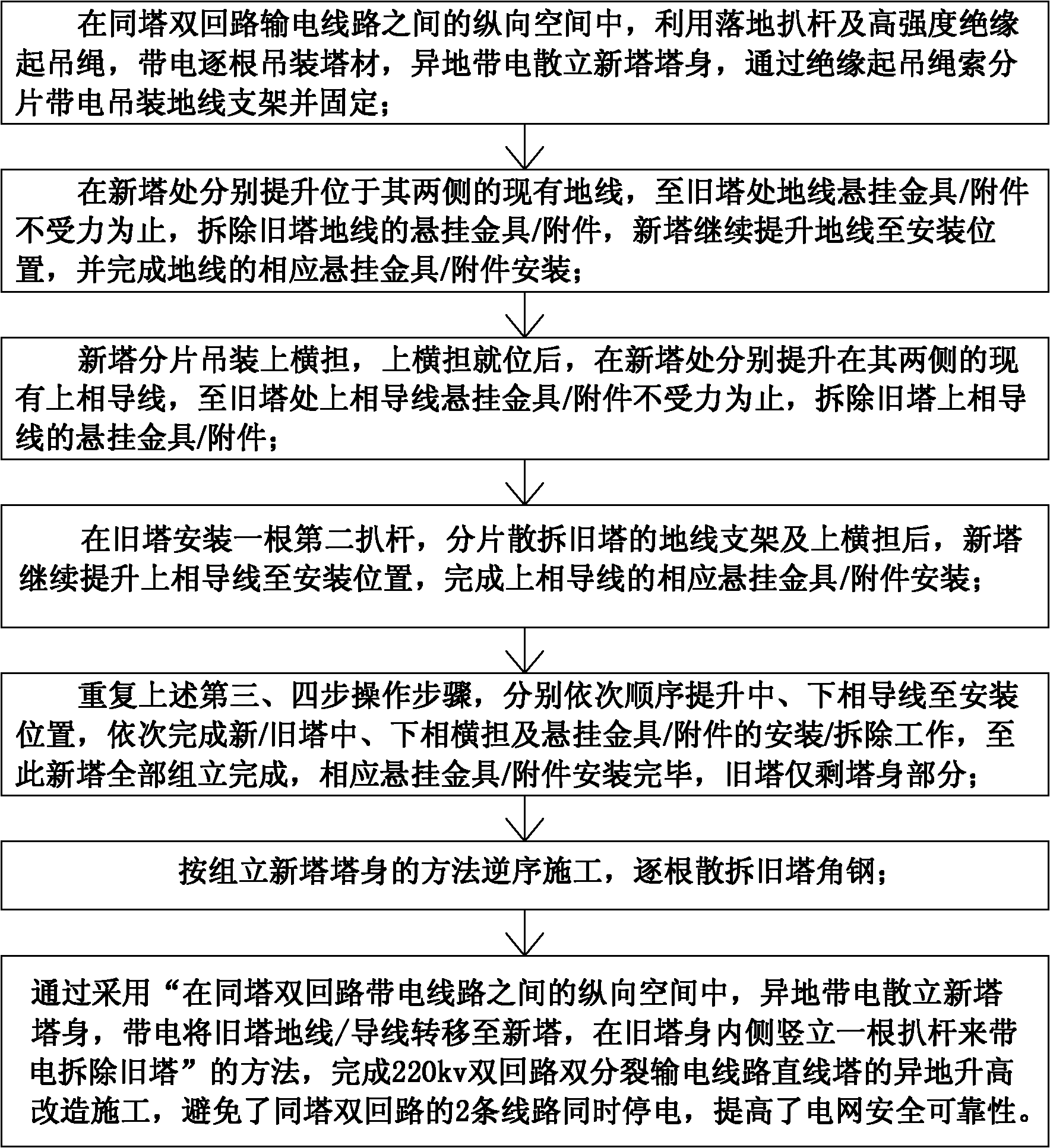

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

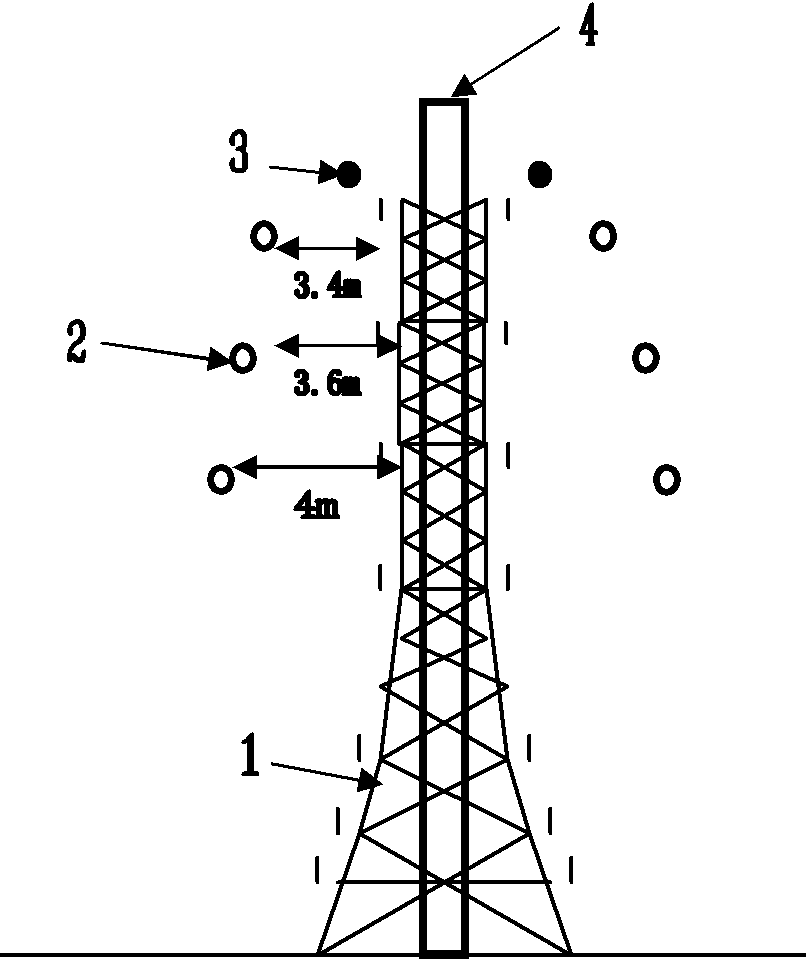

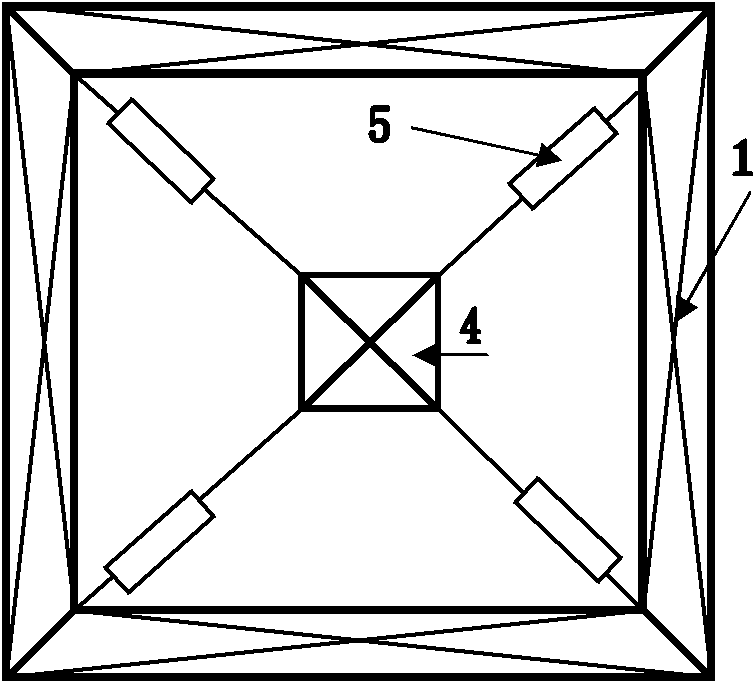

[0053] figure 1 Among them, the technical solution of the present invention provides a double-circuit double-split transmission line straight line tower live lifting transformation method, including the existing old tower and the same-tower double-circuit transmission line fixed on it, and the double-circuit transmission line includes A set of single-sided / single-circuit three-phase transmission lines on both sides of the existing old tower and a ground wire above the single-side / single-circuit transmission line.

[0054] Note that in the "same-tower double-circuit transmission line" described in this technical solution, at least one of the loops (or the transmission line located on one side of the iron tower) is in a live running state, which is the implementation of this technical solution. premise, so it will not be emphasized or repeated hereafter.

[0055] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com