High precision control device of windmill generator damp load

A wind-driven generator, high-precision technology, applied in the direction of controlling generators, control systems, electrical components, etc., can solve the problems of increased product cost, increased difficulty in switching tube selection, large inrush current of switching tubes, etc., to improve control accuracy , The effect of reducing the difficulty of selection and easy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

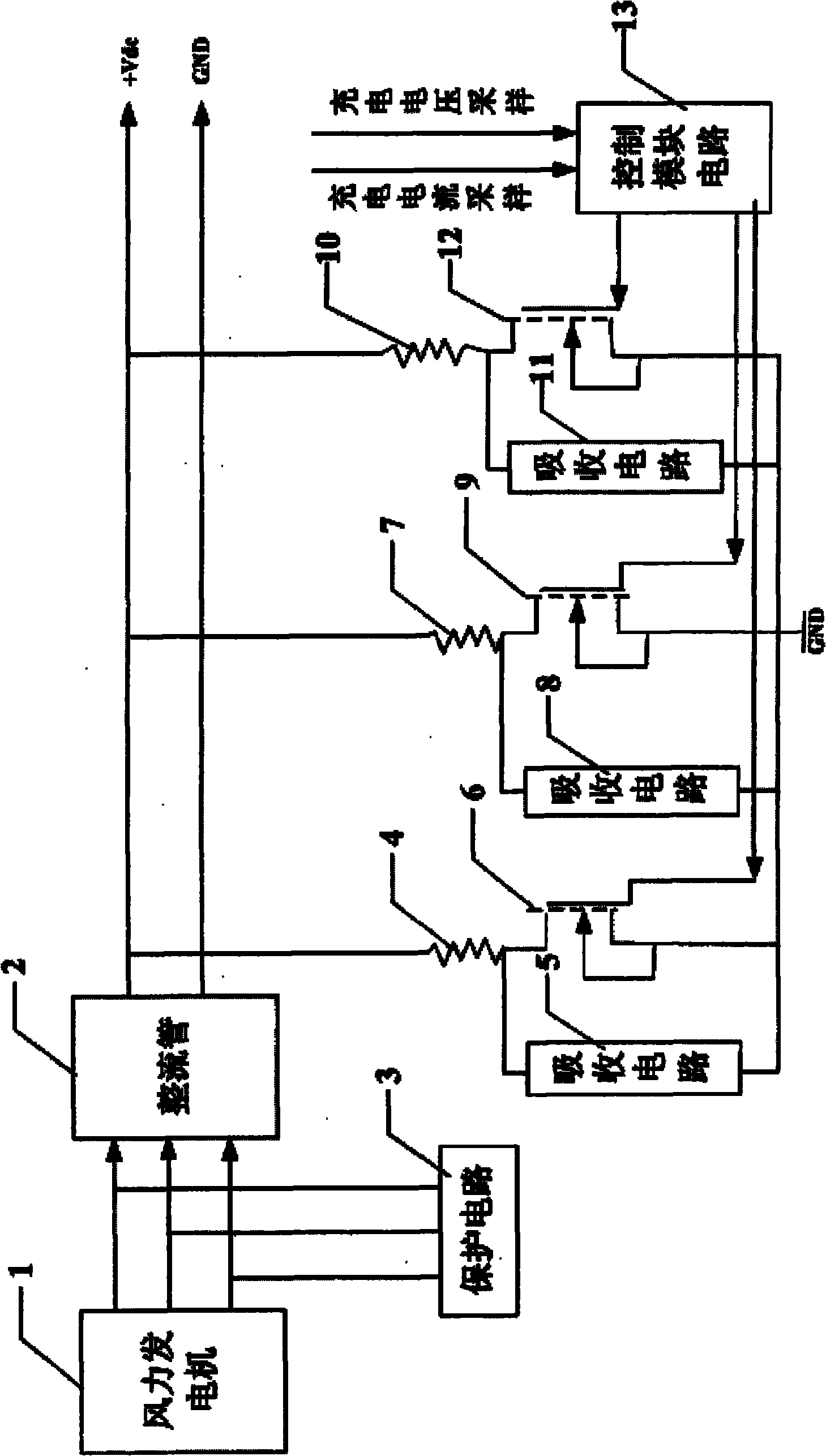

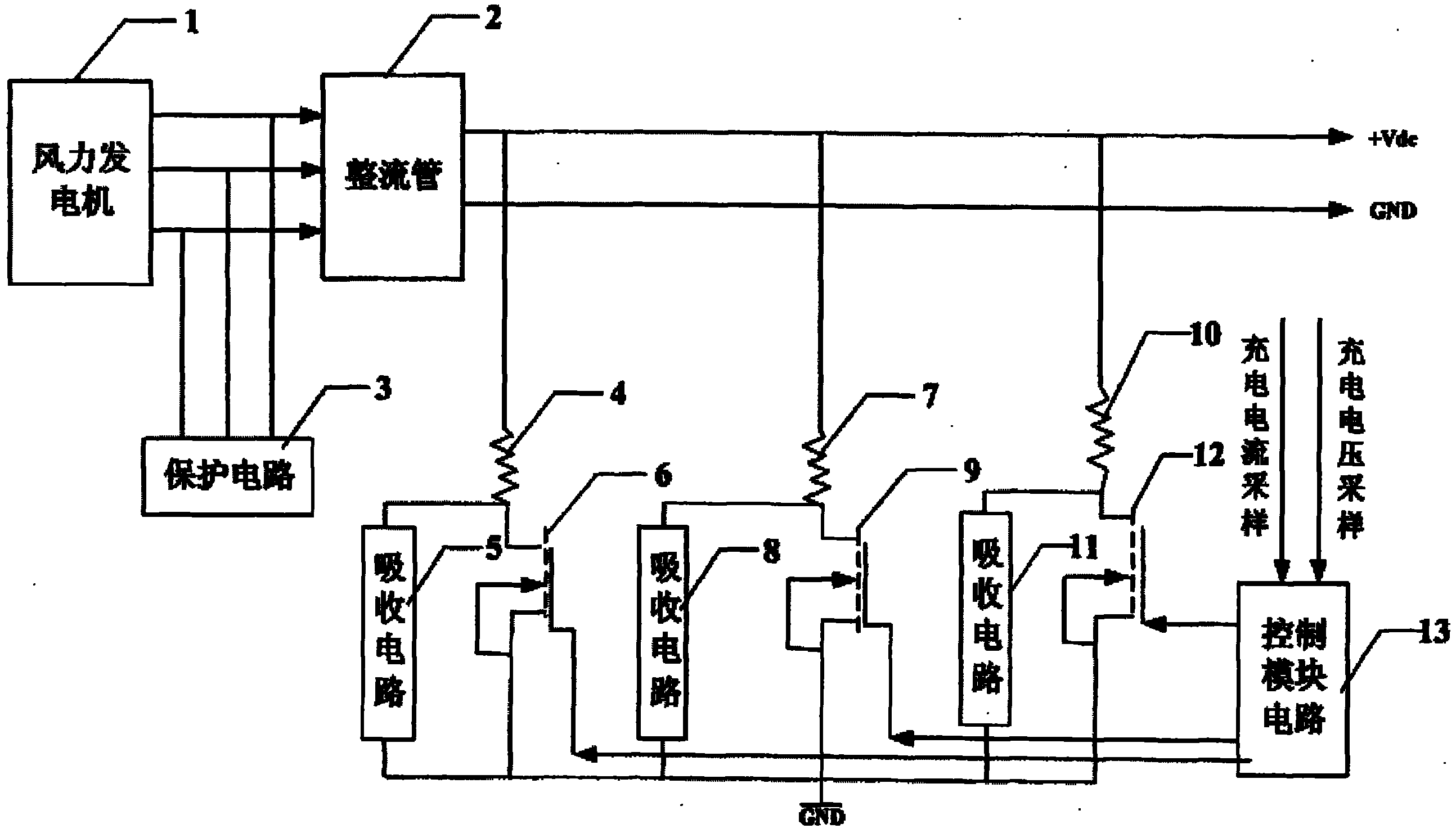

[0022] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, it is a device for high-precision control of unloading load of wind turbine, including wind turbine 1, protection circuit 3, rectifier tube 2, unloading load, absorption circuit, MOS tube and control module circuit, wind power generator The three-phase output of wind turbine 1 is directly connected to the rectifier tube 2, and the three-phase output of wind turbine 1 is also connected to the protection circuit 3; one end of unloading load a4, unloading load b7, and unloading load c10 is respectively connected to the rectifier tube On the positive pole of the DC output of 2, the other end of unloading load a4, unloading load b7, and unloading load c10 are respectively connected to the D stage of MOS tube a6, MOS tube b9, and MOS tube c12; MOS tube a6, MOS tube b9, the S level of M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com