Microsphere screening device

A screening device and screening technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of large workload of polymer microsphere selection and difficulty in selection of hollow glass microspheres with thick walls, etc. The effect of reducing the difficulty of selection, improving the efficiency of selection, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

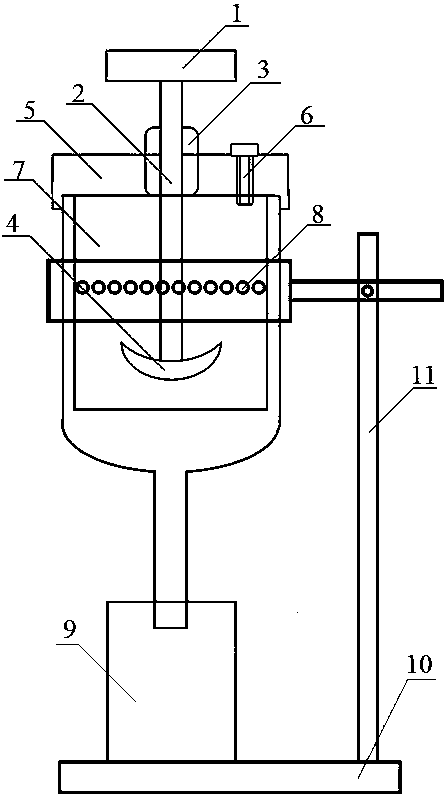

[0021] figure 1 It is a schematic diagram of the structure of the microsphere screening device of the present invention.

[0022] exist figure 1 Among them, the microsphere screening device of the present invention includes a stirring assembly, a dynamic seal adapter 3, a sealing cover 5, a screening cavity 7, a recovery liquid cup 9, a fixed table 10 and a fixed support 11; the stirring assembly contains a stirring Handle 1, stirring rod 2 and stirring blade 4; the connection relationship of the above-mentioned devices is that the sealing cover 5 is provided with a sieving liquid injection port 6, and the screening cavity 7 contains two layers of walls inside and outside; the stirring rod 2 The top end is embedded and fixedly connected with the stirring handle 1, the lower end of the stirring rod 2 is fixedly connected with the stirring blade 4, and the lower end of the stirring rod 2 and the stirring blade 4 pass through the sealing cover 5 and are located in the inner wall...

Embodiment 2

[0034] The structure of this embodiment is the same as that of Embodiment 1, except that the screening cavity 7 and the recovery liquid cup 9 are made of transparent glass material; the number of wall holes 8 is 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com