Self-propelled hydraulic plate for conveying tower drum

A hydraulic plate and self-propelled technology, which is applied in the direction of tilting and carrying vehicles, can solve problems such as difficult to avoid obstacles, rollovers, and restrictions on tower transportation, so as to avoid road reconstruction and remove obstacles. Technical and economic value, the effect of guaranteeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

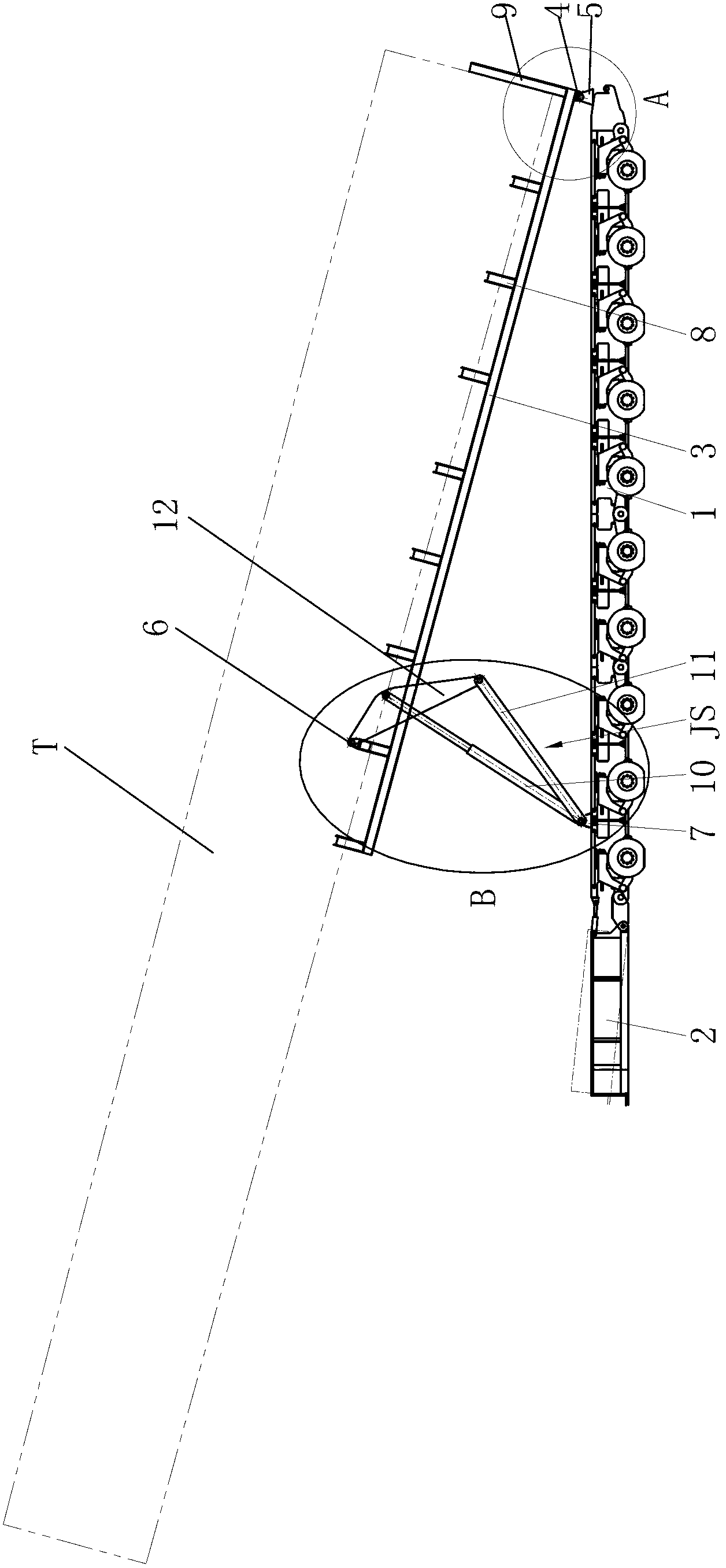

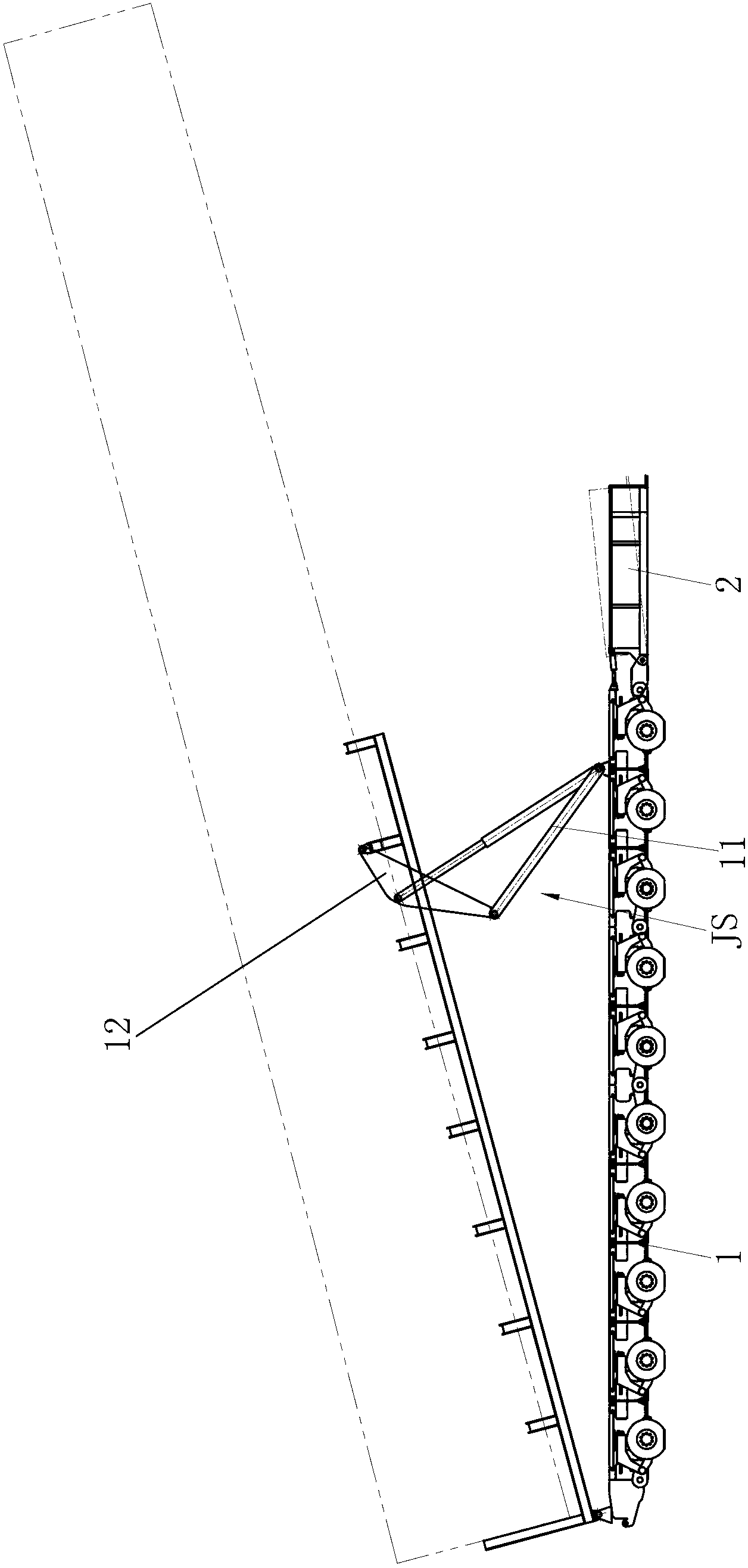

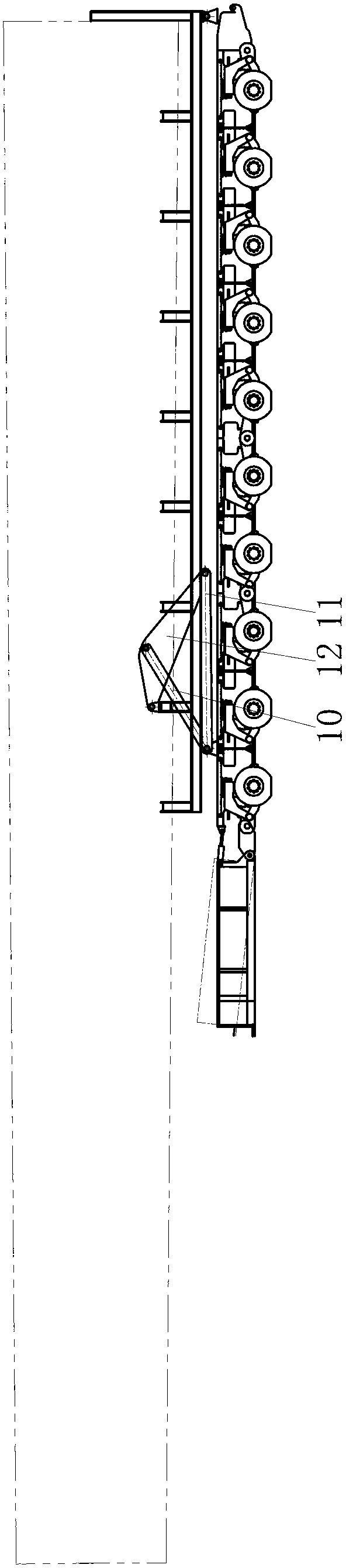

[0030] From Figures 1 to 7It can be seen that this embodiment consists of a hydraulic plate 1, a power module 2, a support frame 3, a first lug 4, a second lug 5, a third lug 6, a fourth lug 7, a support block 8, and a tower The baffle plate 9 and the lifting tool JS are composed, wherein the hydraulic plate 1 adopts the existing structure. When the hydraulic plate 1 encounters a bumpy road, its wheels can move up and down, so that the upper surface of the hydraulic plate 1 can be kept horizontal. And the specific structure of the hydraulic plate 1 will not be repeated here. In order to pull the hydraulic plate 1 and provide hydraulic pressure for the wheels of the hydraulic plate 1 to move up and down, a power module 2 is specially arranged at the front end of the hydraulic plate 1. The power module 2 is an existing structure, and the power module 2 and The hydraulic plate 1 together constitutes a self-propelled hydraulic plate, and the specific connection structure between...

Embodiment 2

[0037] refer to Figures 1 to 7 shown, combined with Figure 5 It can be seen that in this embodiment, the above-mentioned lifting tool JS is an oil cylinder, the piston rod of the oil cylinder is hinged to the third lug 6, and the cylinder liner of the oil cylinder is hinged to the fourth lug 7, The rest of the structure of this embodiment is completely the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com