Brake system for a vehicle

A braking system and service braking technology, applied in the direction of brakes, vehicle components, brake transmission devices, etc., can solve the problems of high cost and expensive manufacturing of the braking system, and achieve the effect of enhancing the parking brake pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

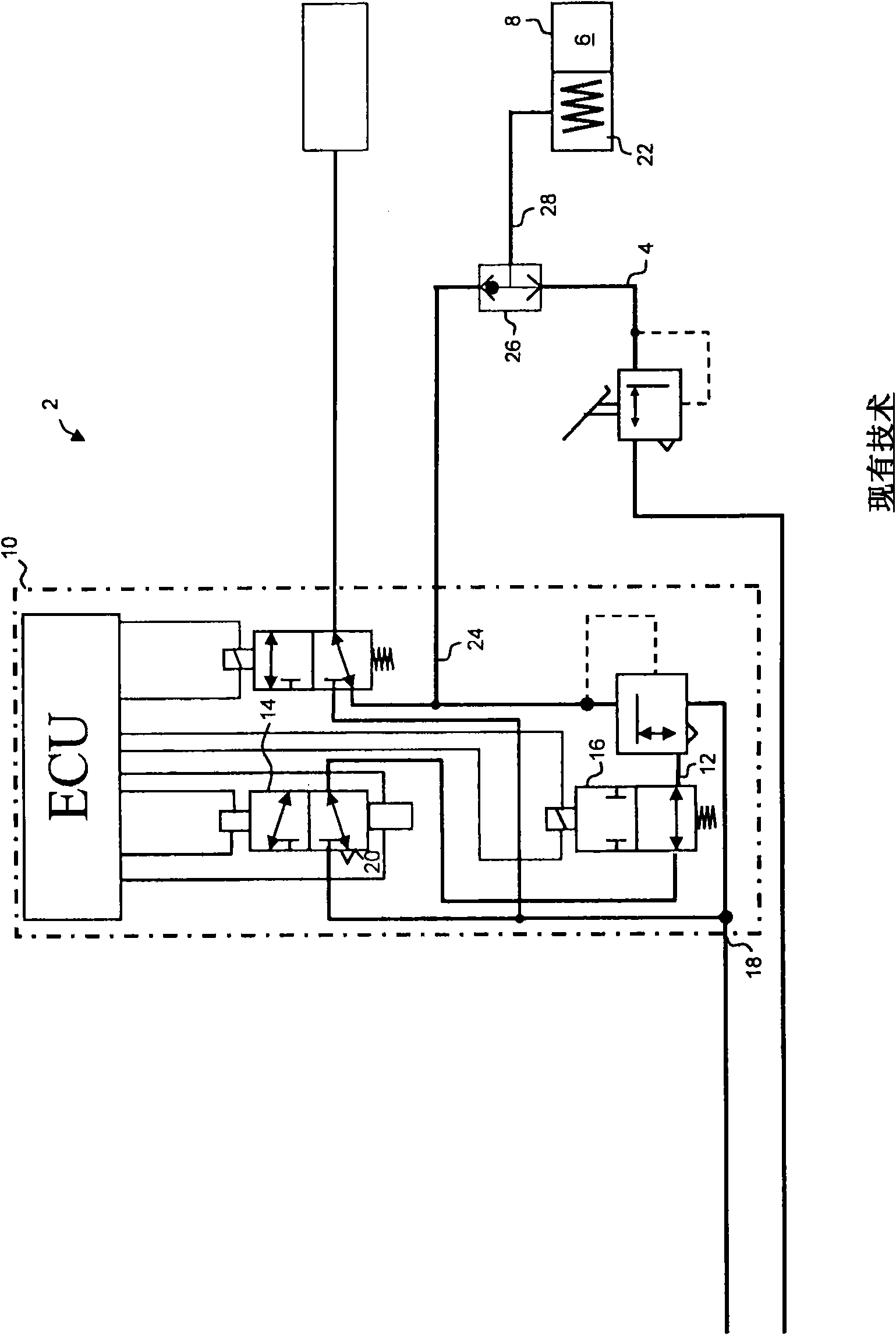

[0021] figure 1 It has been introduced in the preamble of the description in order to illustrate the important features of the prior art.

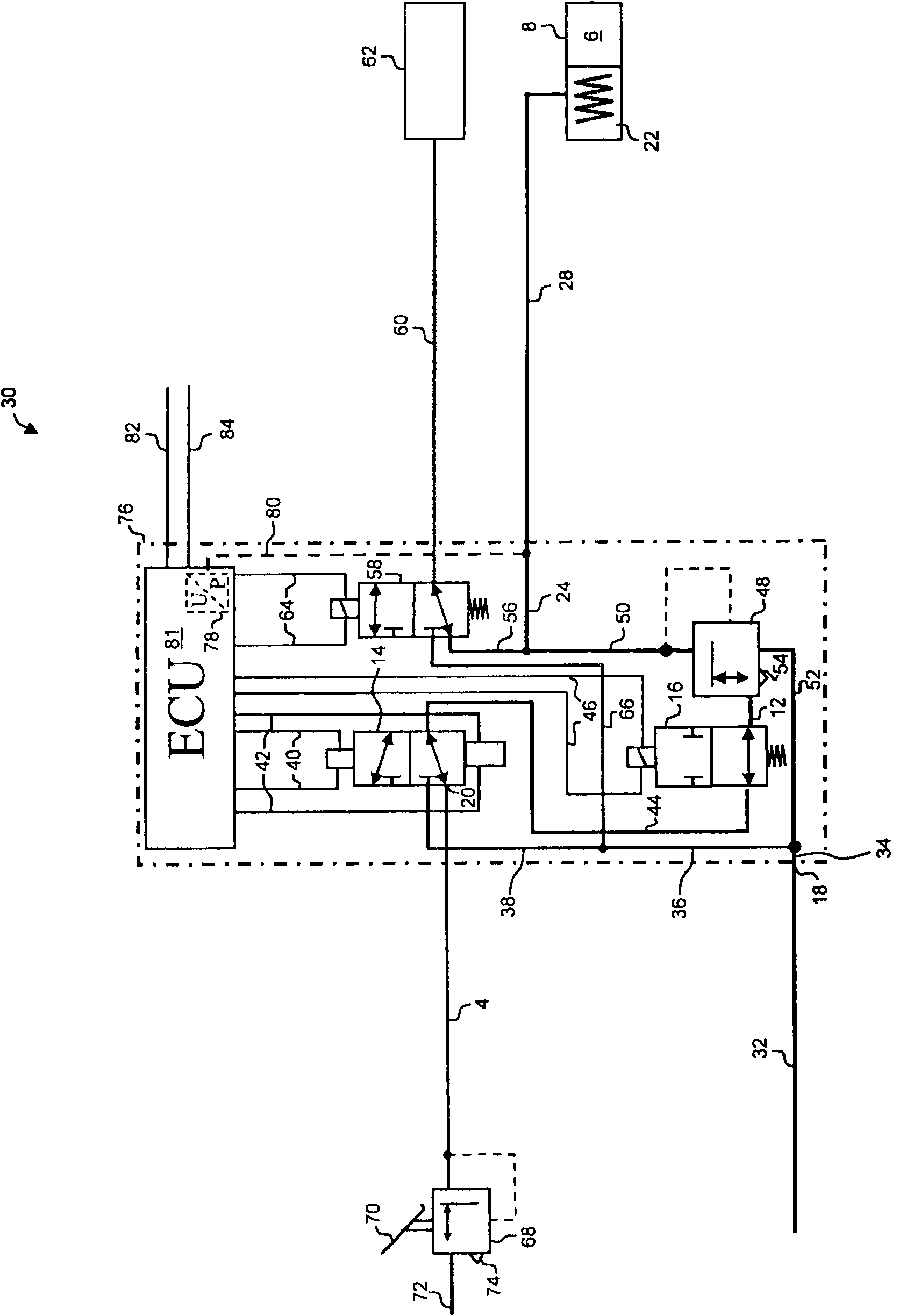

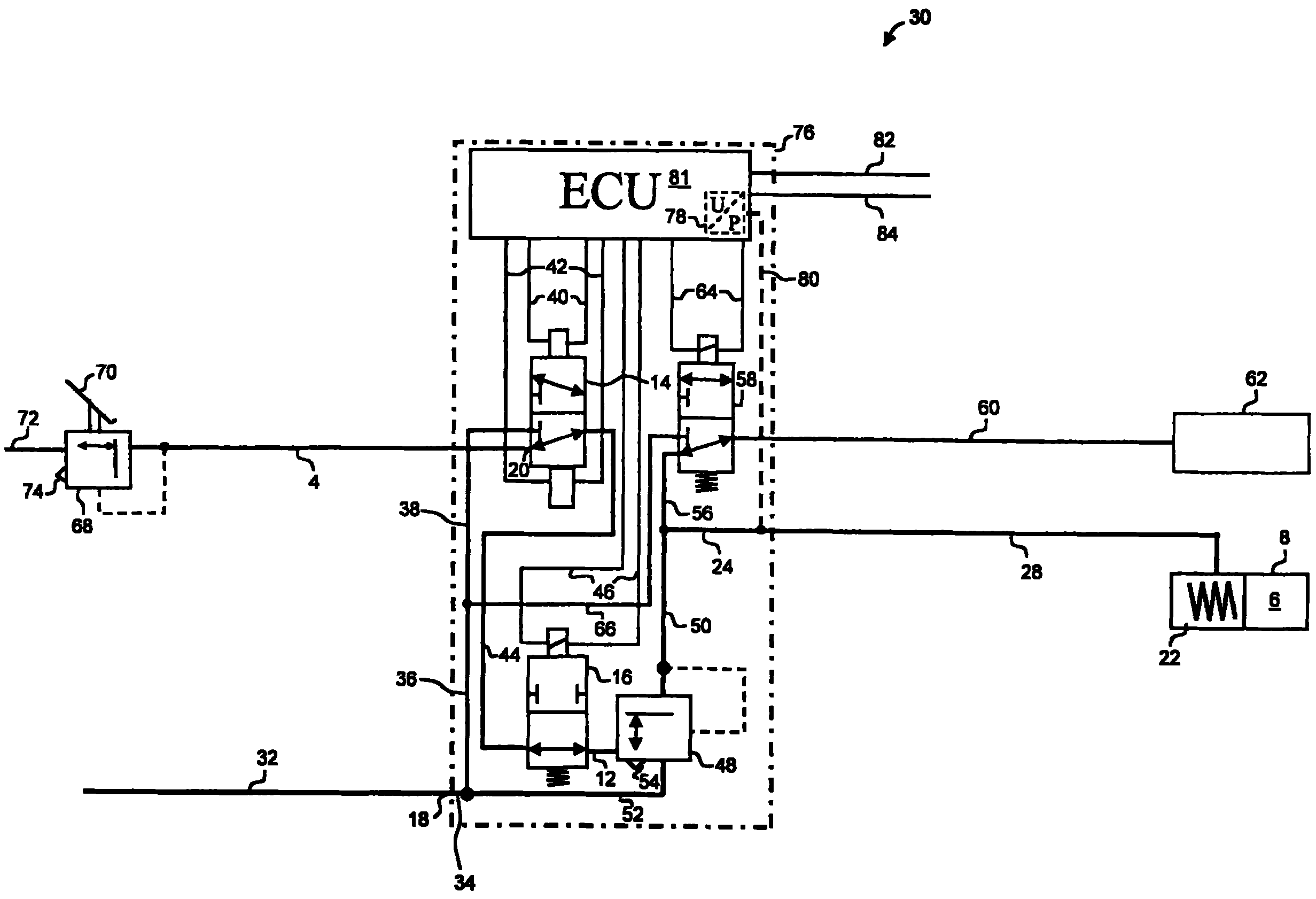

[0022] figure 2 Shown is a braking system 30 according to the invention which is partly compatible with the figure 1 The braking system 2 of the prior art is the same. In this respect, the same reference numerals designate the same components and refer to the corresponding above-described embodiments.

[0023] In the case of the brake system 30 , compressed air with a reserve air pressure emerges from a compressed air reserve container (not shown) via a compressed air line 32 to the ventilation inlet 18 . Compressed air lines 34 , 36 and 38 lead compressed air to the first solenoid valve 14 , which is implemented as a bistable valve. The bistable valve 14 is switchable in two switching states. To this end, the magnetic coil is controlled via electrical lines 40 and 42 to switch between said states. The bistable valve 14 remains in i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com