Jig for assembling belt and method for assembling belt and method for producing belt

An assembling method and technology for assembling belts, which are applied to household appliances, other household appliances, belts, etc., can solve the problem of not developing a method and device for assembling a plurality of blocks on an endless carrier, and achieve improved manufacturability, easy assembly, The effect of efficient assembly of the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

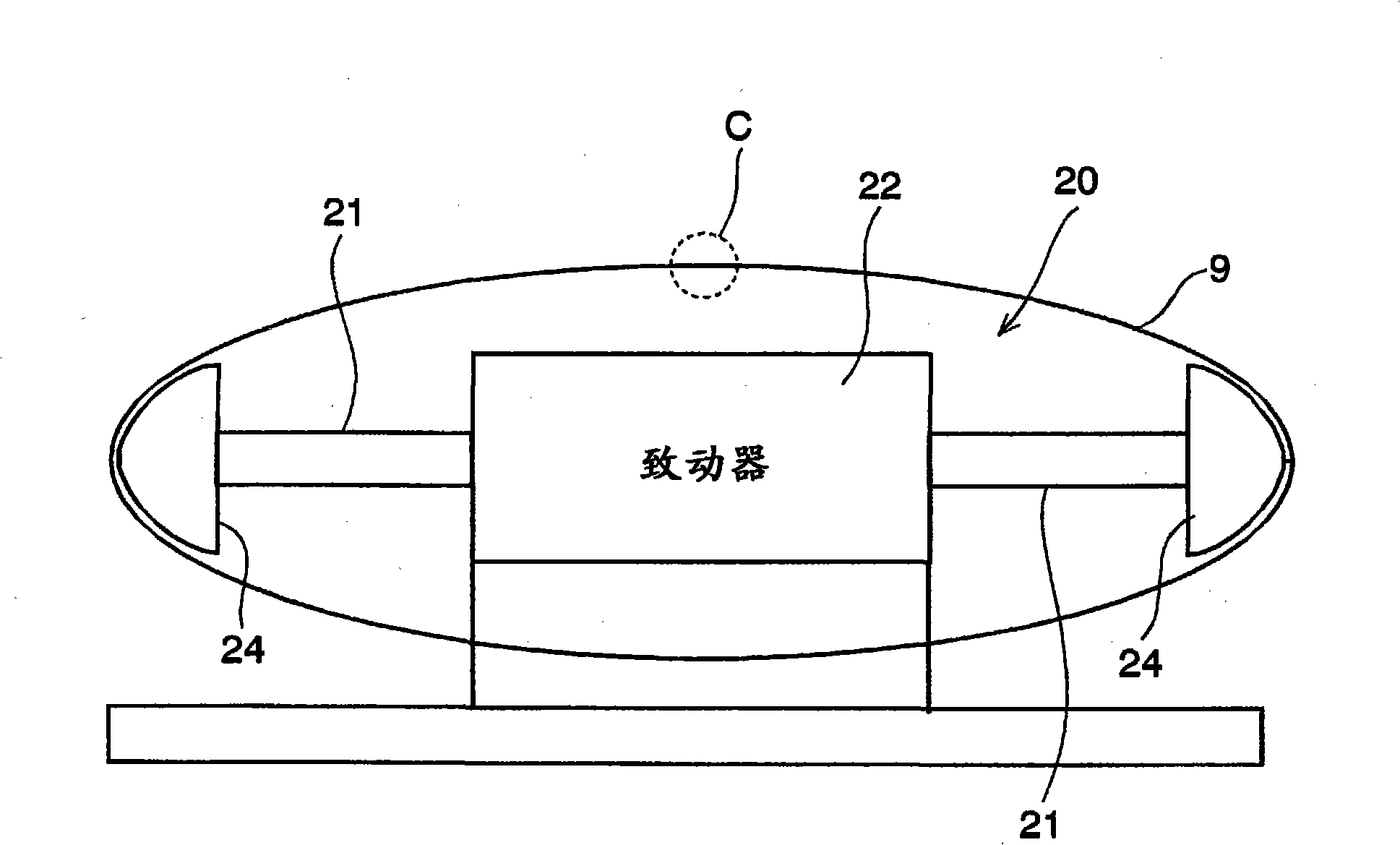

[0035] Next, specific examples of the present invention will be described. The belt is used in, for example, a continuously variable transmission, and is configured to be sandwiched in a V-shaped cross-sectional winding groove formed on the outer peripheral portion of the pulley so that the belt is transmitted by friction generated between the belt and the pulley. torque. An example of it is shown schematically in Figure 5 , the belt 1 is wound around a driving pulley 2 and a driven pulley 3 constituting a continuously variable transmission. These pulleys 2 and 3 are configured by arranging a fixed pulley and a movable pulley each having a tapered surface facing each other, thereby forming a winding groove 4 having a V-shaped cross section between these pulleys, and passing an actuator 5 such as a hydraulic cylinder. The width of the winding groove 4 is changed by moving the movable pulley back and forth relative to the fixed pulley.

[0036] The belt used in this way is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com