Molding machine for compressed nutrition pot

A nutrient bowl and forming machine technology, which is applied in the fields of application, cultivation, agriculture, etc., can solve the problems of difficult control of the amount of seeds and nutrient soil, low efficiency, slow working speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

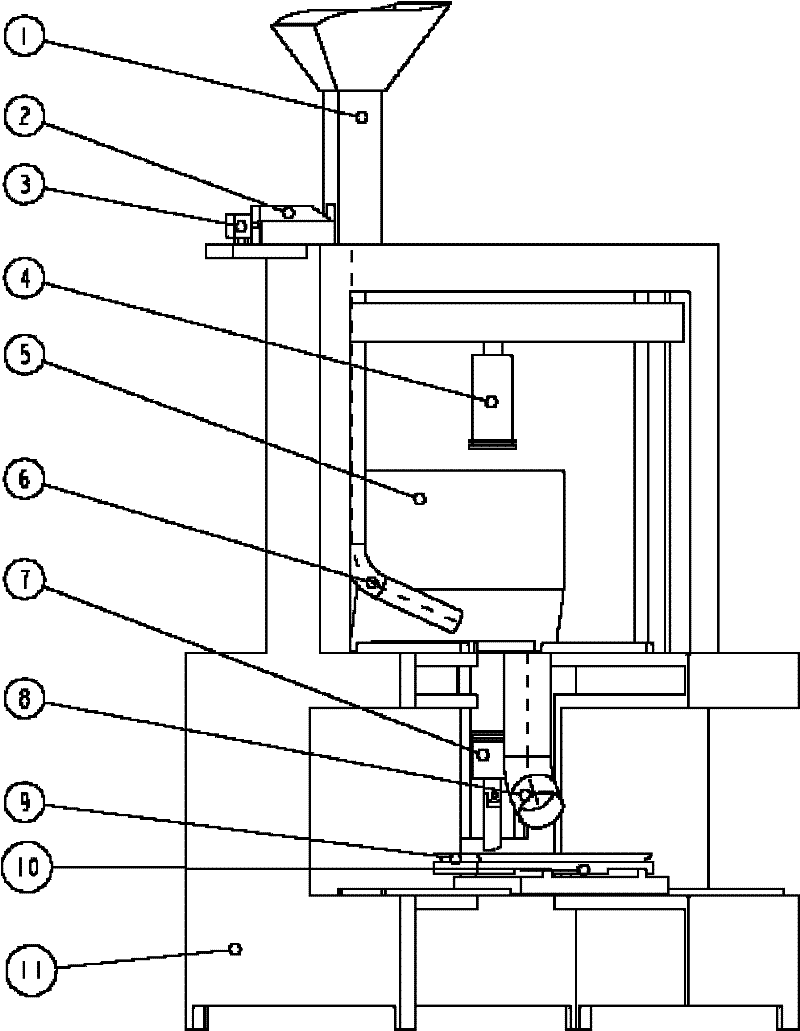

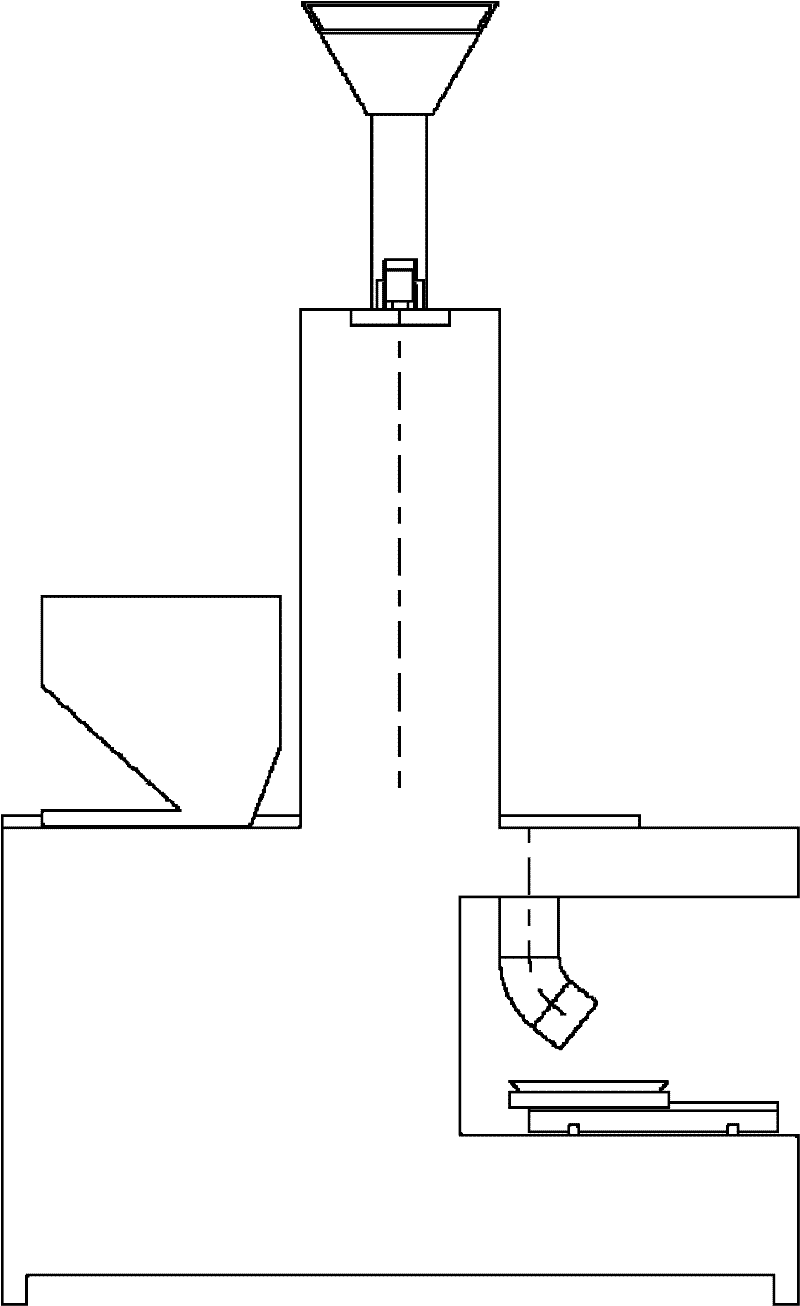

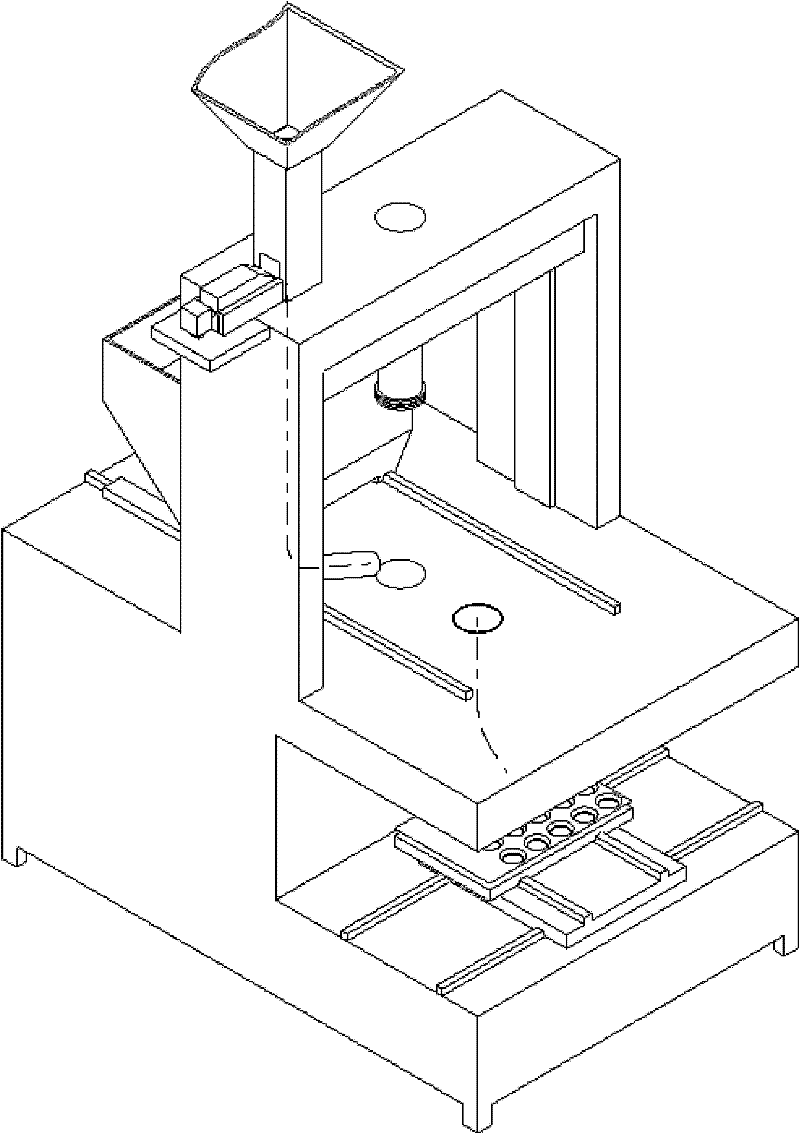

[0018] Markings in the attached drawings:

[0019] attached figure 1 Middle, 1—seed box, 2—shift fork, 3—electromagnet, 4—upper punch, 5—nutrition bowl base material box, 6—seed introduction tube, 7—lower punch, 8—nutrition bowl conduit, 9 —nutritional bowl tray, 10—mobile workbench, 11—rack;

[0020] attached Figure 4 , attached Figure 6 Among them, 12—the covering layer of the compressed nutrition bowl, 13—the seeds, and 14—the main body of the compressed nutrition bowl.

[0021] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0022] as attached figure 1 It is a schematic diagram of a compressed nutrition bowl molding machine, and its main components are: seed box 1, shift fork 2, electromagnet 3, upper punch 4, nutrition bowl base material box 5, seed introduction tube 6, lower punch 7, nutrition bowl catheter 8, nutrition bowl tray 9, mobile workbench 10, frame 11. The electrical control part is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com